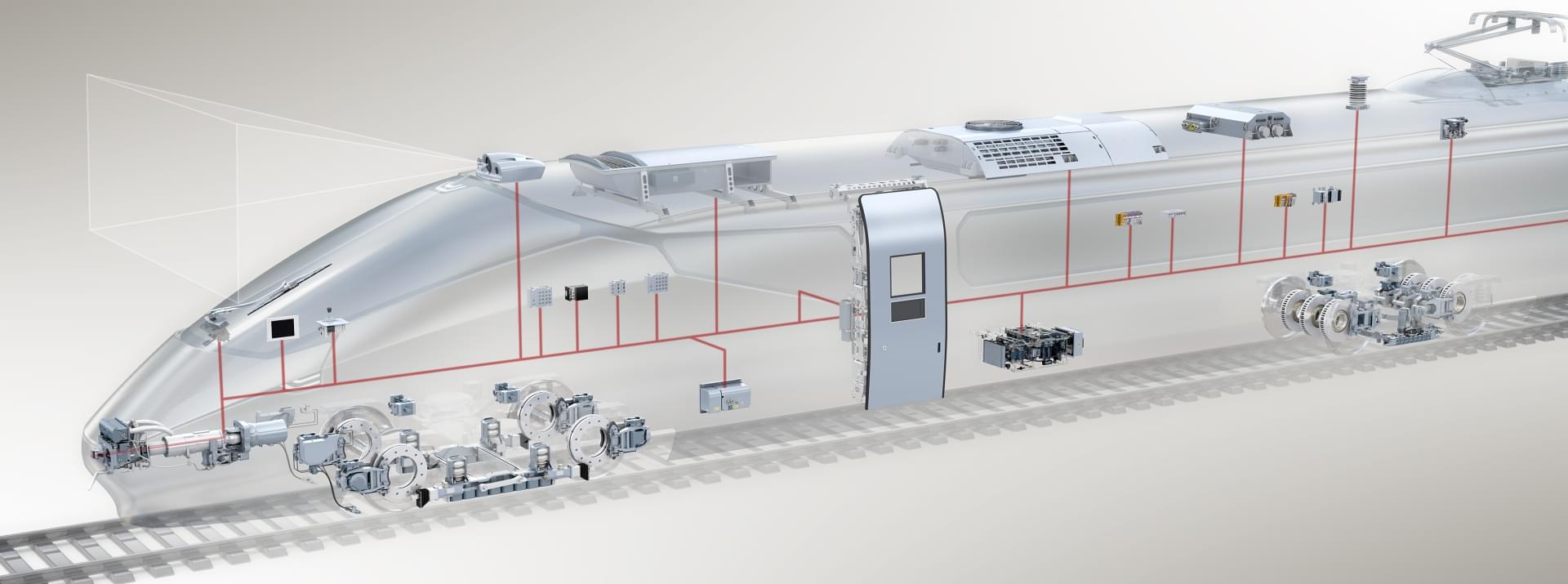

Modernizing vehicles often represents an economically attractive alternative to buying brand-new ones. But that’s not all. As far as passengers are concerned, a thoughtfully modernized train is the same as a new one. Four sample projects show just what extraordinary things Knorr-Bremse’s aftermarket and modernization specialist RailServices can achieve.

Certain popular upgrades have become “classics” – but they’re not the only options. Classic upgrades include, for example, retrofitting new braking systems, so trains can travel faster for longer and yet still stop in time. New entrance systems are another classic option, allowing passengers with limited mobility to travel comfortably by train.

But even leaving aside all the classic upgrades such as braking, entrance and HVAC systems, Knorr-Bremse RailServices offers an impressively broad, state-of-the-art portfolio of modernization options. Because even modest adjustments can elevate passenger safety and comfort to a whole new level.

This is where RailServices brings two major advantages to bear. First, a worldwide service network. And second, access to the expertise of the entire Knorr-Bremse Group. Two advantages that result in integrated, highly customized, highly reliable modernization solutions.

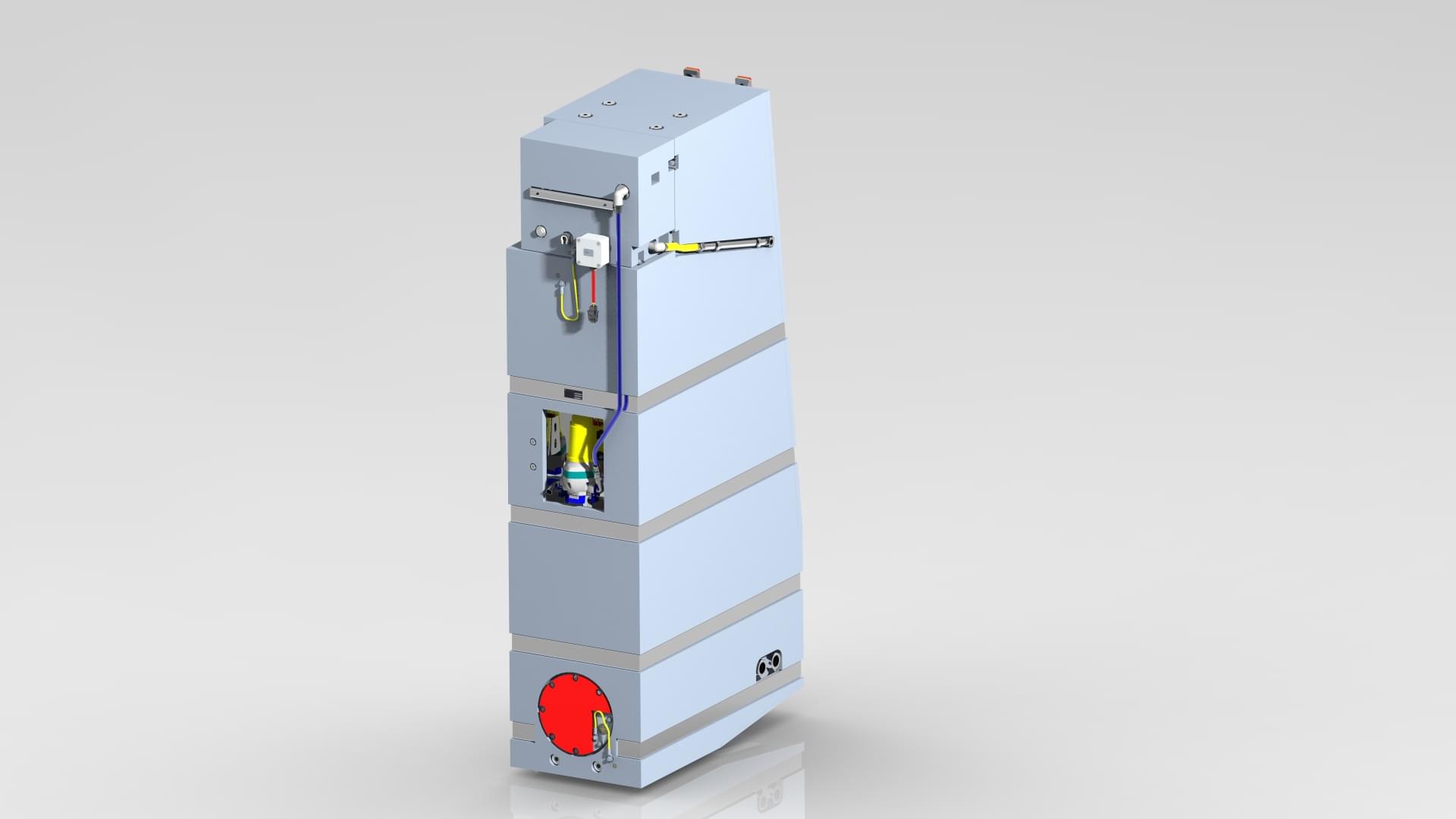

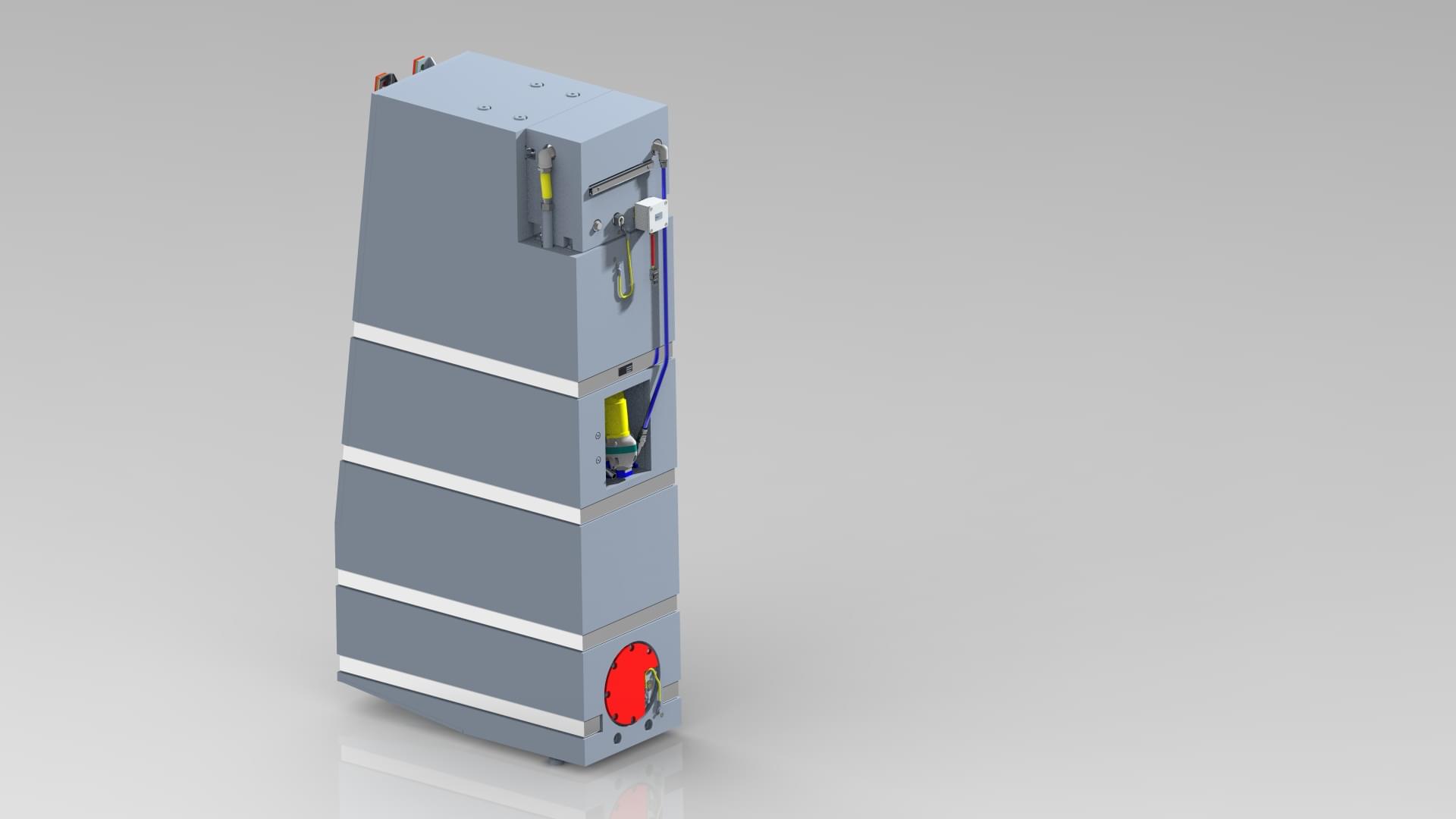

Clean and comfortable: new sanitary systems

Modern sanitary systems based on vacuum technology are very complex, providing clean, hygienic, water-saving and a proper disposal of wastewater. First, the various water and wastewater systems, customer-specific electrohydraulic kits and tanks must be integrated with each other, then with a control system directly linked to the Train Control & Management System (TCMS), and finally with the rail vehicle itself. As an experienced specialist, Knorr-Bremse RailServices covers every stage of this process – now with the further strengthening of Evac, Knorr-Bremse’s new brand specializing in integrated rail-vehicle sanitary systems.

RailServices successfully completed over the years modernizing VB2N commuter railcars operated by SNCF (France), as well as Vivalto and Minuetto commuter railcars owned by Trenitalia (Italy) by fitting closed, electronically controlled sanitary systems. The icing on the cake? The RailServices engineers successfully concealed all the water and wastewater tanks behind cabin walls or beneath the seating. And in trains run by private rail operator Trentino Transporti, based on the Coradia platform, RailServices replaced the existing manual toilet doors with automatic ones. Currently on going is also the replacement of the previously installed wastewater tanks of the Trenitalia High Speed Trains ETR600-610 with an improved solution based on new design.

Reliable and long-lasting: new on-board power converters

Together with Kiepe Electric, the Knorr-Bremse Group’s e-engineering specialist, RailServices has just upgraded the on-board power converters in 39 Alstom CITADIS C-Class vehicles operated by Yarra Trams in Melbourne. The modernization was carried out following a rapid decline in the availability of spare parts for the old converters. By replacing the components, RailServices improved the rail vehicles’ reliability and availability – but the modernization project also significantly extended their operating lives. RailServices and Kiepe Electric have carried out similar modernization projects on Siemens Combino D-Class vehicles.

Efficient and safe: new sanding systems

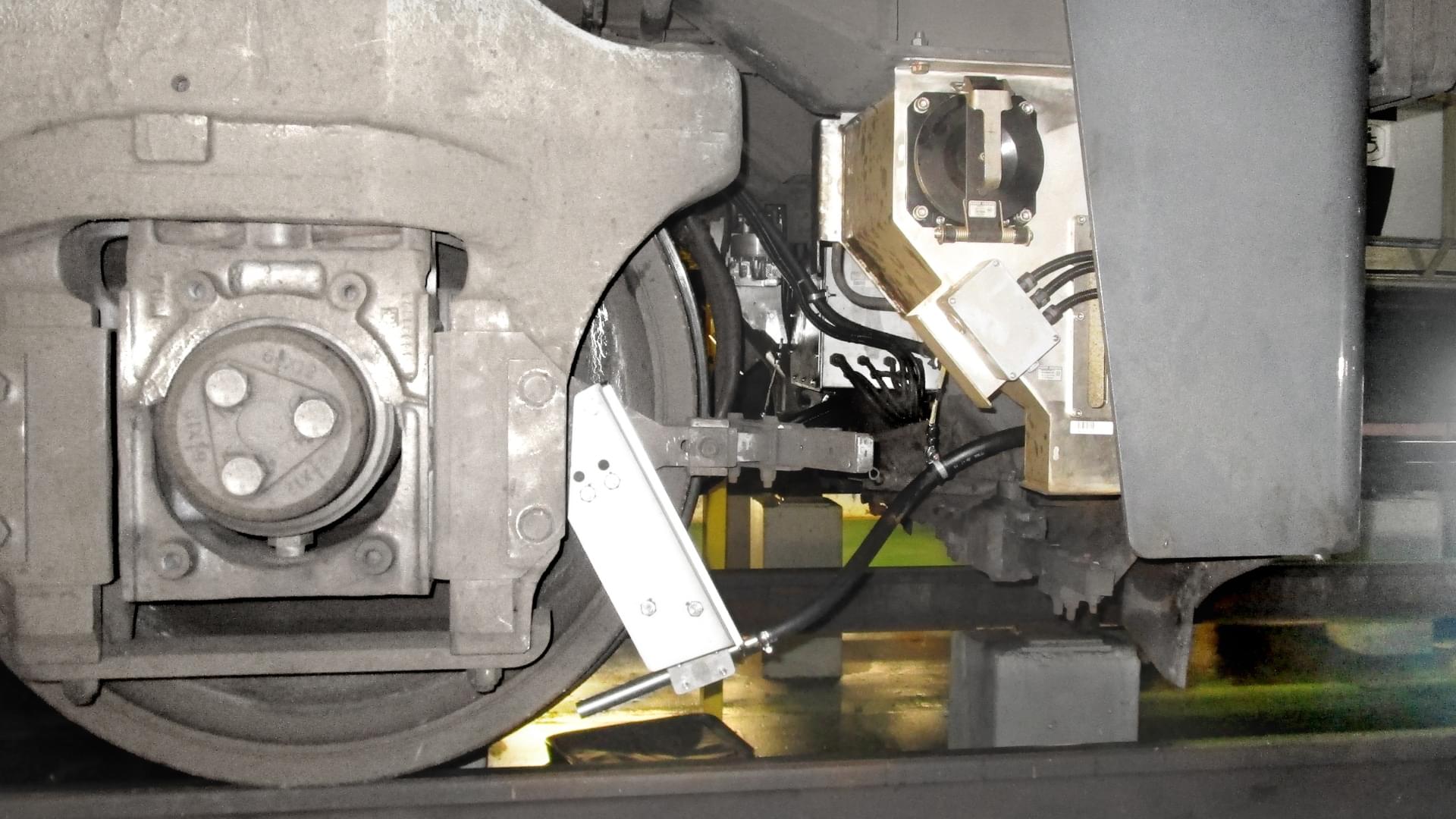

Autumn leaves are notorious: by covering rails in the fall, they dramatically reduce the level of adhesion between wheel and rail. Sanding systems are the answer – they use a jet of air to blow sand toward the point of wheel-rail contact, where it is ground up to produce its adhesion-enhancing effect. Sanding systems have also proved invaluable for radically improving friction coefficients when trains are moving off. This helps to reduce the intervals between trains, increasing service frequency.

Over time, yesterday’s crude sanding systems have evolved into today’s sophisticated high-tech systems featuring pressure-proportional application, sensors for monitoring sand levels and sand flow, air-drying systems for keeping hoses clear, and heated sand nozzles. Modern, speed-dependent sanding has become the benchmark – first, by reducing the quantity of sand consumed and the amount of fine dust produced, and second, by reducing downtime because sandboxes need filling less often. All of which has significant benefits for operators.

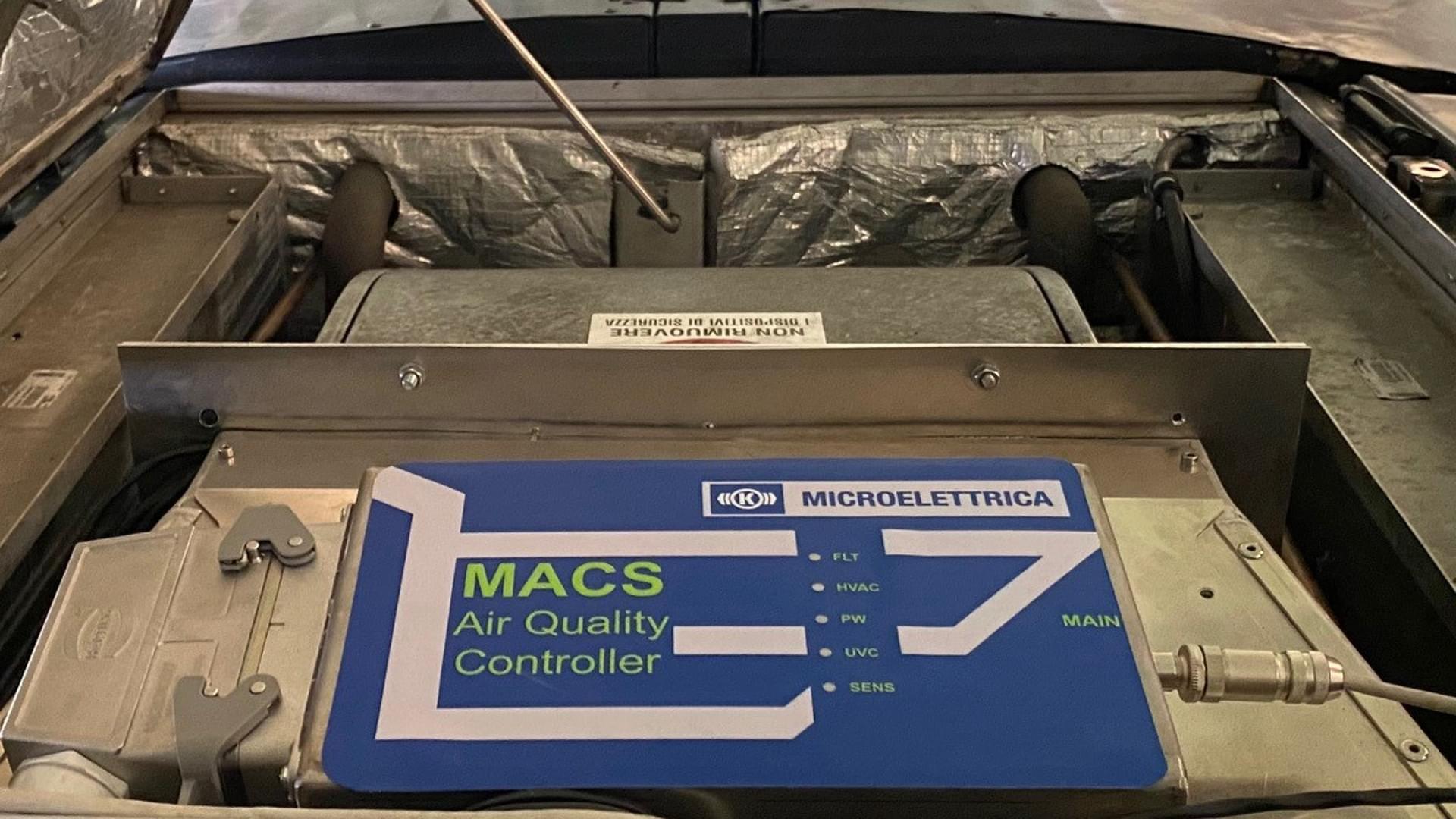

Invisible but invaluable: air quality monitoring system

Based on the same principle as their energy metering systems (for measuring energy consumption), Knorr-Bremse company Microelettrica has developed a system that measures air quality in trains. Easy to retrofit in almost any air duct, this plug-and-play solution provides passengers as well as operators with real-time feedback on the status of the air quality. At the same time, the system is also capable of monitoring the effectiveness of any disinfection measures. Microelettrica has already produced the first prototypes, which are currently undergoing field trials in Trenitalia’s Vivalto trains.