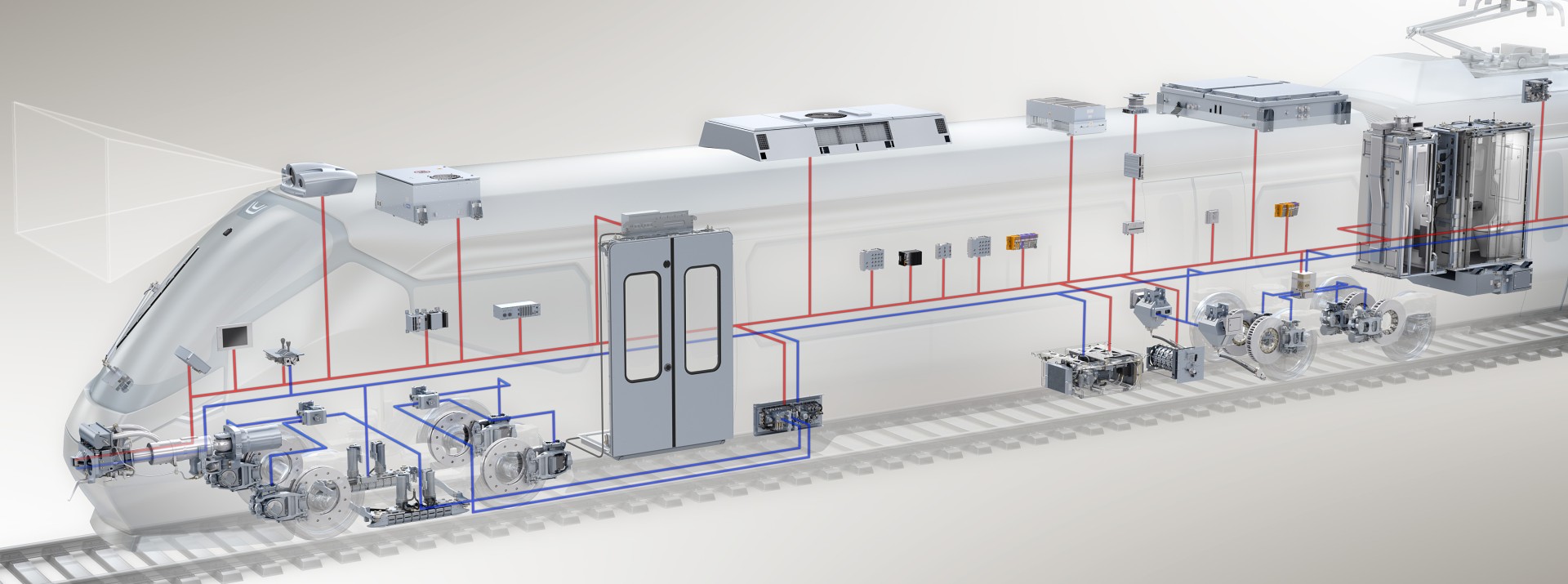

Regional trains bring commuters in to the city from the surrounding area and take holidaymakers and day trippers out into the countryside. Transportation associations run networks covering entire regions. They connect provincial stations to the high-speed network and provide a fast link between airports and city centers. The applications for regional trains are probably more diverse than for any other type of rail vehicle – and Knorr-Bremse is an experienced developer of many of their subsystems.

While operators demand reliability and cost-effectiveness, comfort is a priority for passengers – they have come to expect features like wide doors, inter-car gangways and Wi-Fi. Manufacturers supply different traction systems and train configurations depending on the exact nature of the route and the specific requirements. For high passenger capacities, they can either add center cars between the multiple units or design the train as a double-decker from the outset.

CONTACT

80809 München

Deutschland - Germany

sales.sfs@knorr-bremse.com

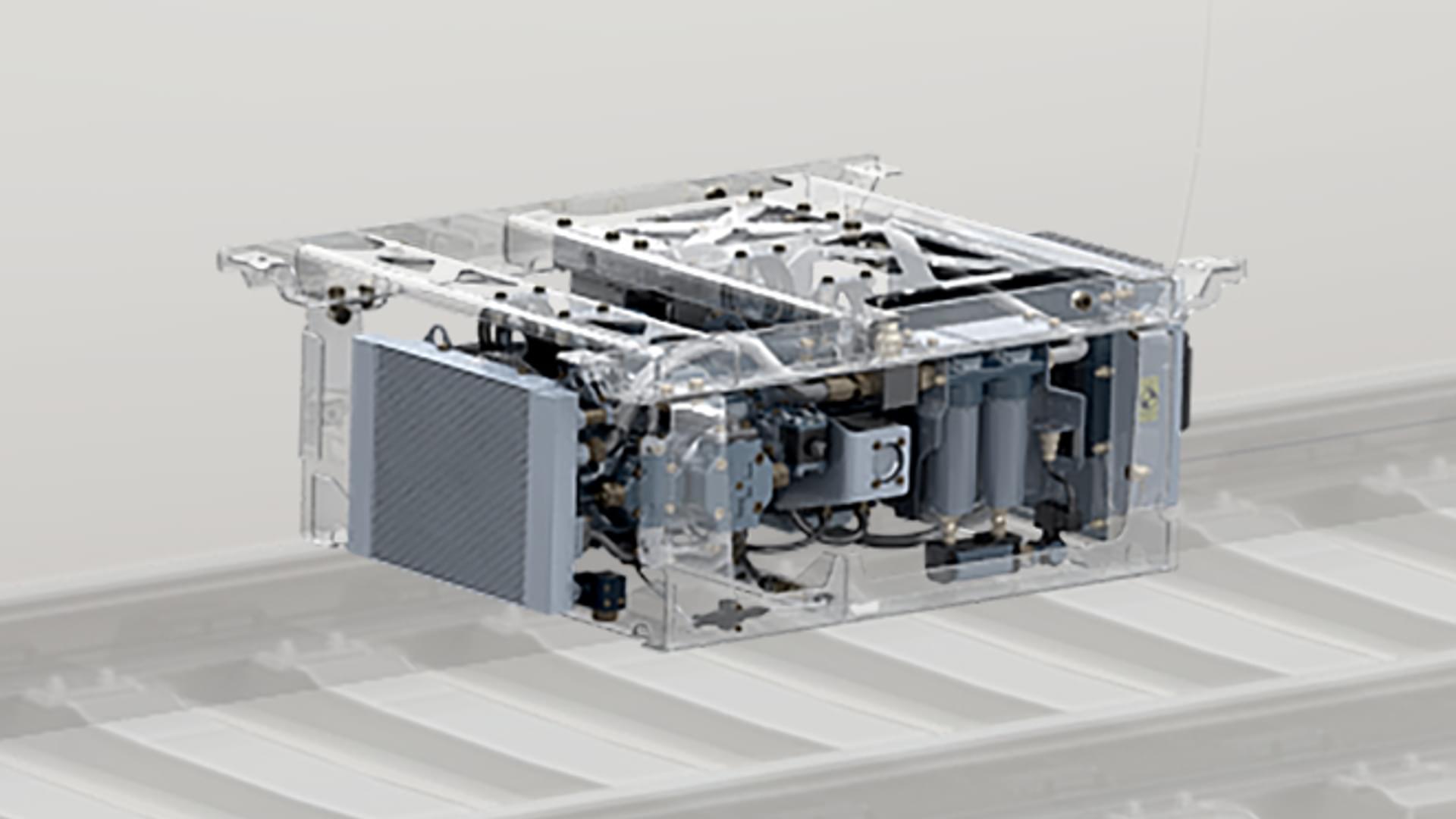

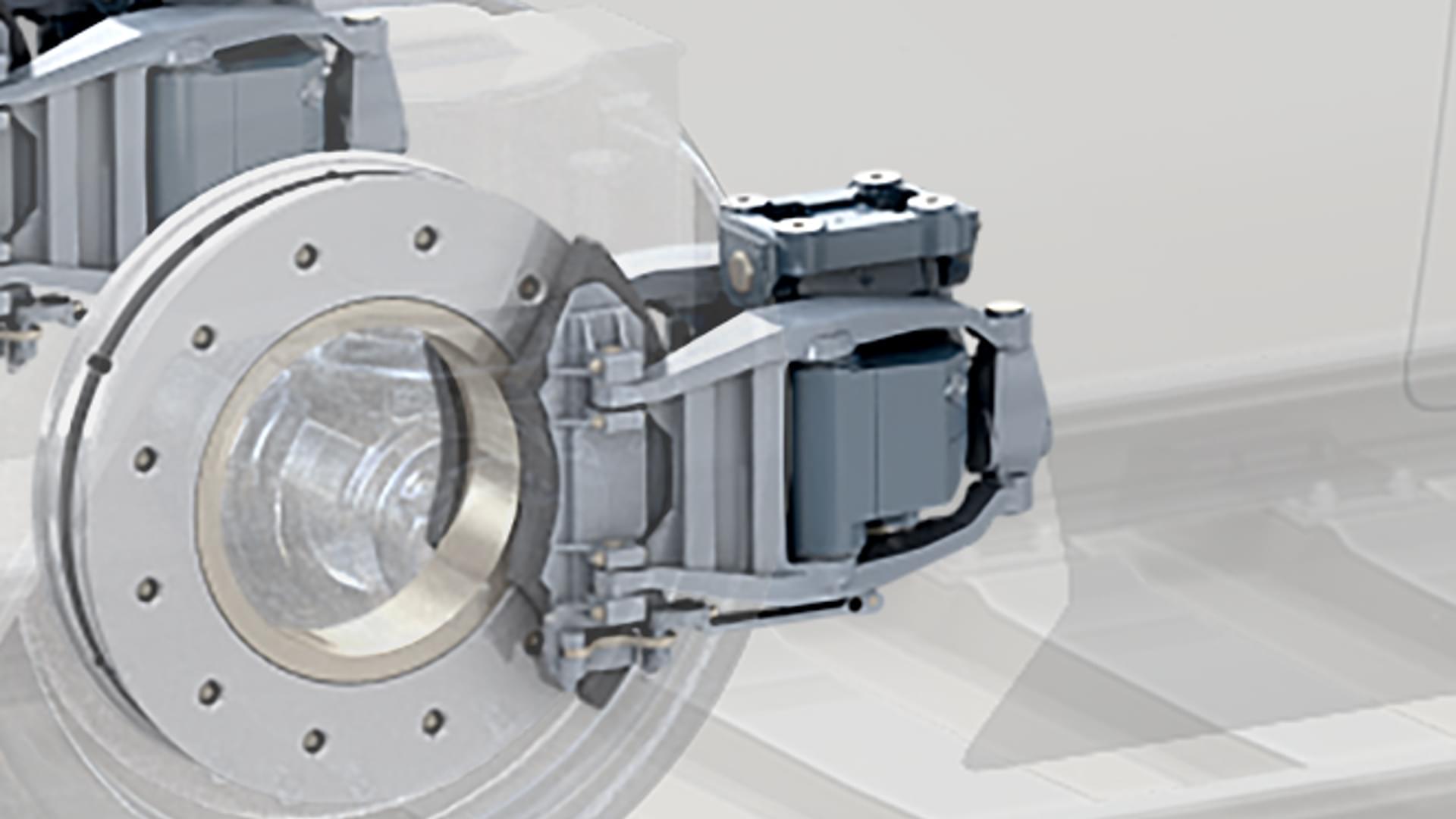

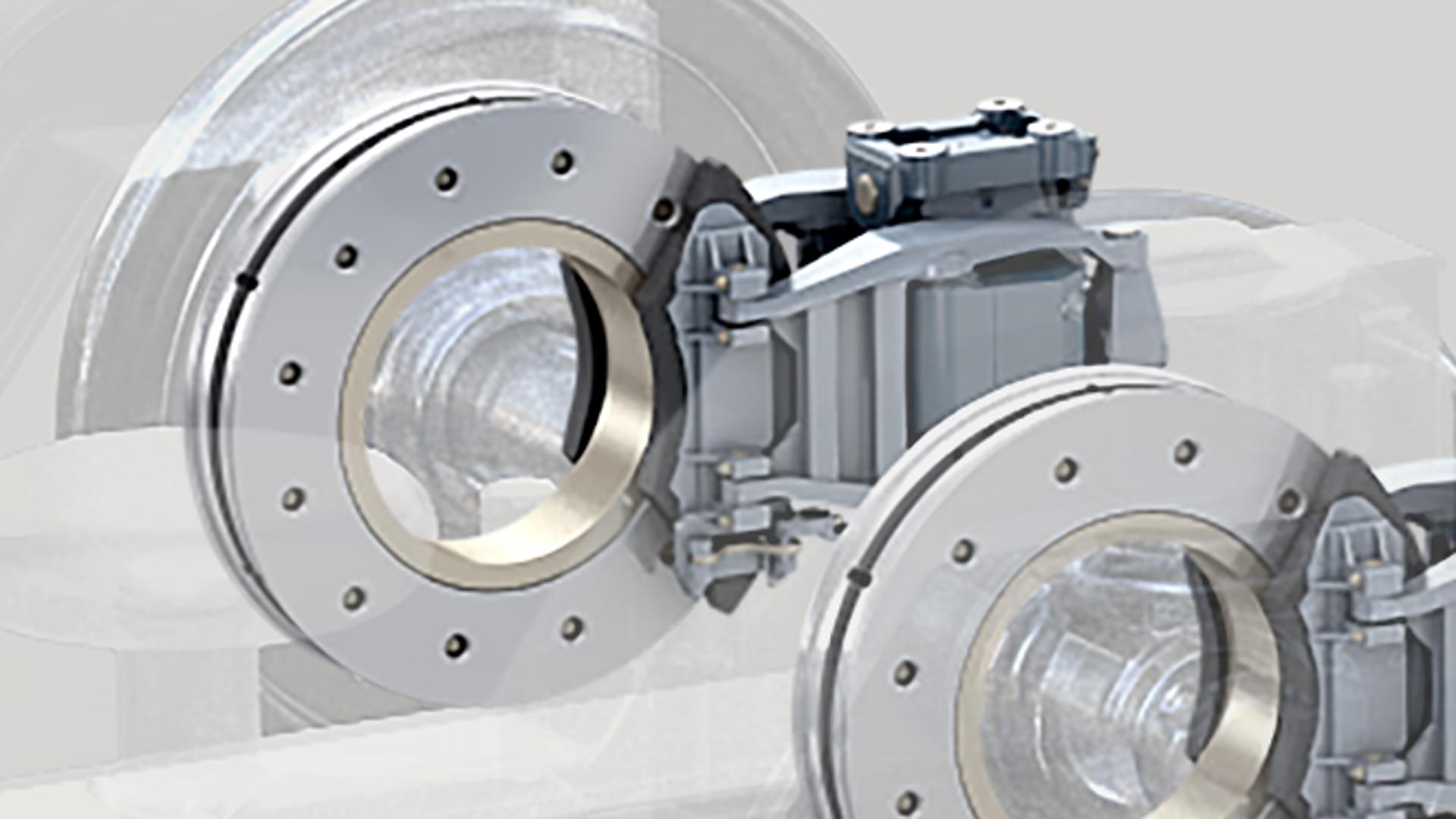

Take a look at the complete range of systems for rail vehicles, from the individual product to intelligent system solutions.

Read more