Whether it is a freight train with several locomotives in North America, the trans-siberian railway in Russia or an intercity train in Europe, it will always need a workhorse to pull or push it along. Locomotives are as diverse as the trains they power. Knorr-Bremse has decades of experience to offer here.

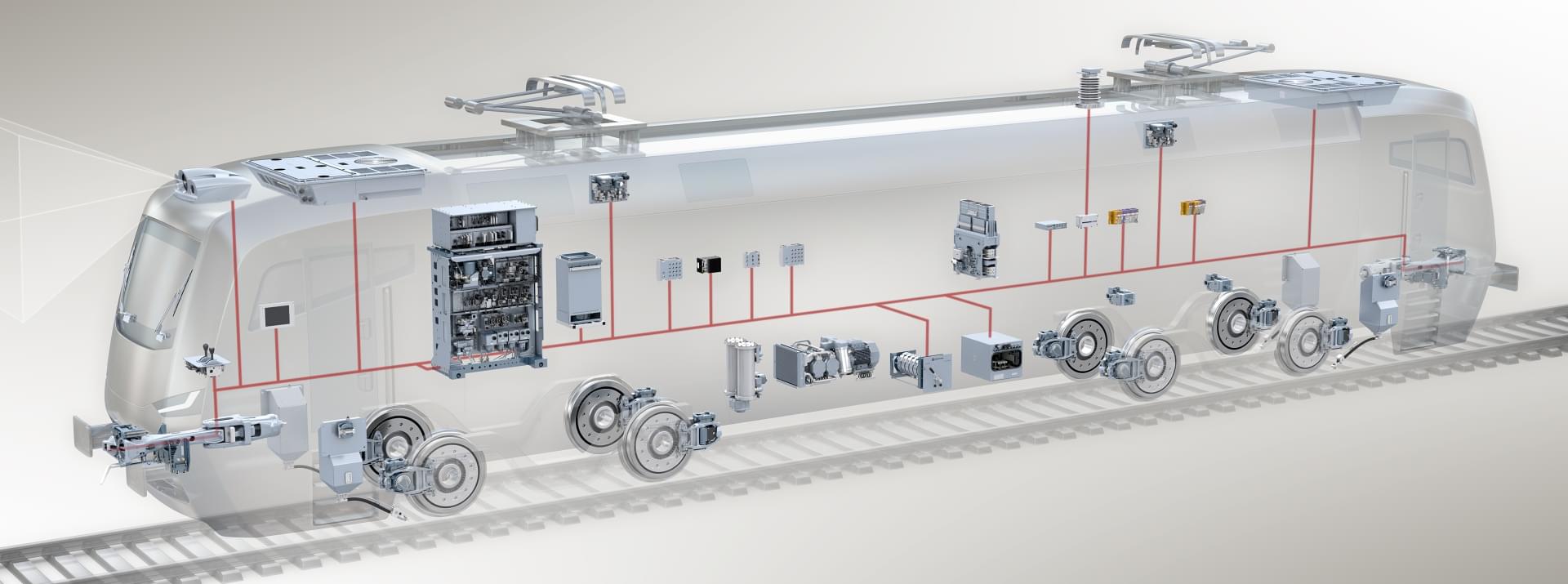

Manufacturers frequently employ a modular approach to develop customized solutions for specific customer requirements. Electric locomotives are widely used in Europe, where much of the rail network is electrified. In North America, on the other hand, diesel-electric locomotives are the norm. Multi-system locomotives combining different traction methods are the ideal solution for operators who use their locomotives flexibly for a range of applications.

CONTACT

80809 München

Deutschland - Germany

sales.sfs@knorr-bremse.com

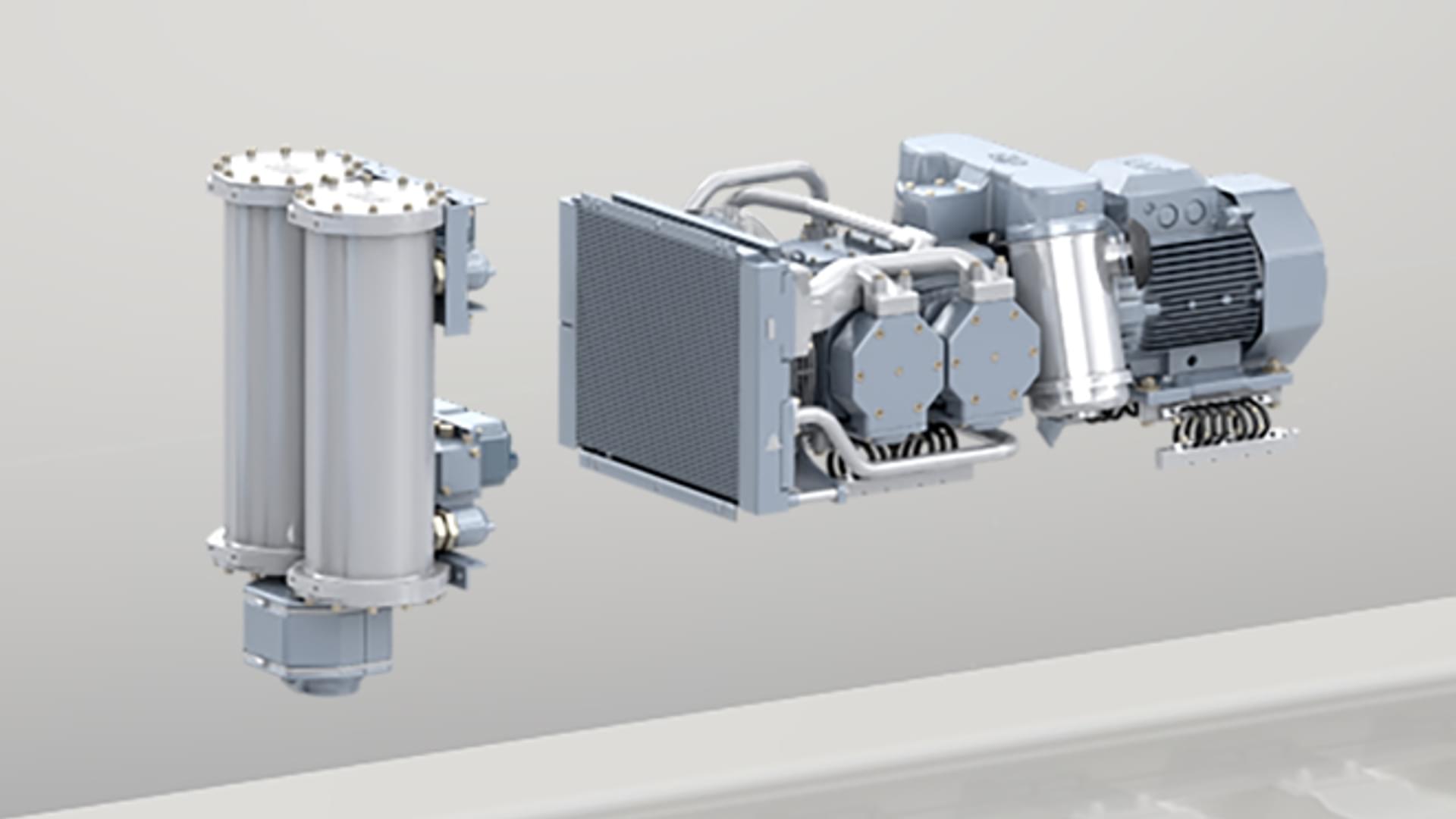

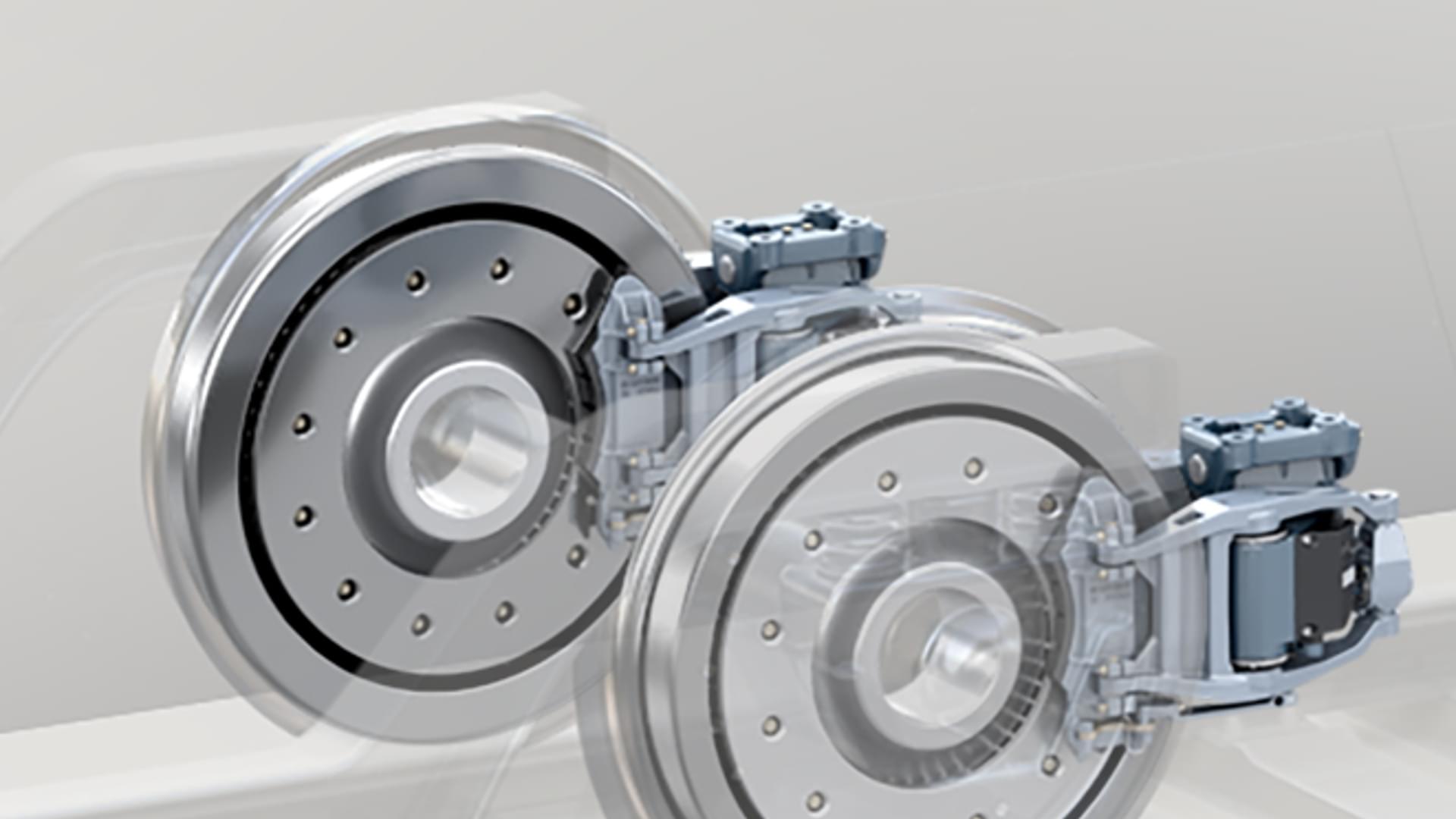

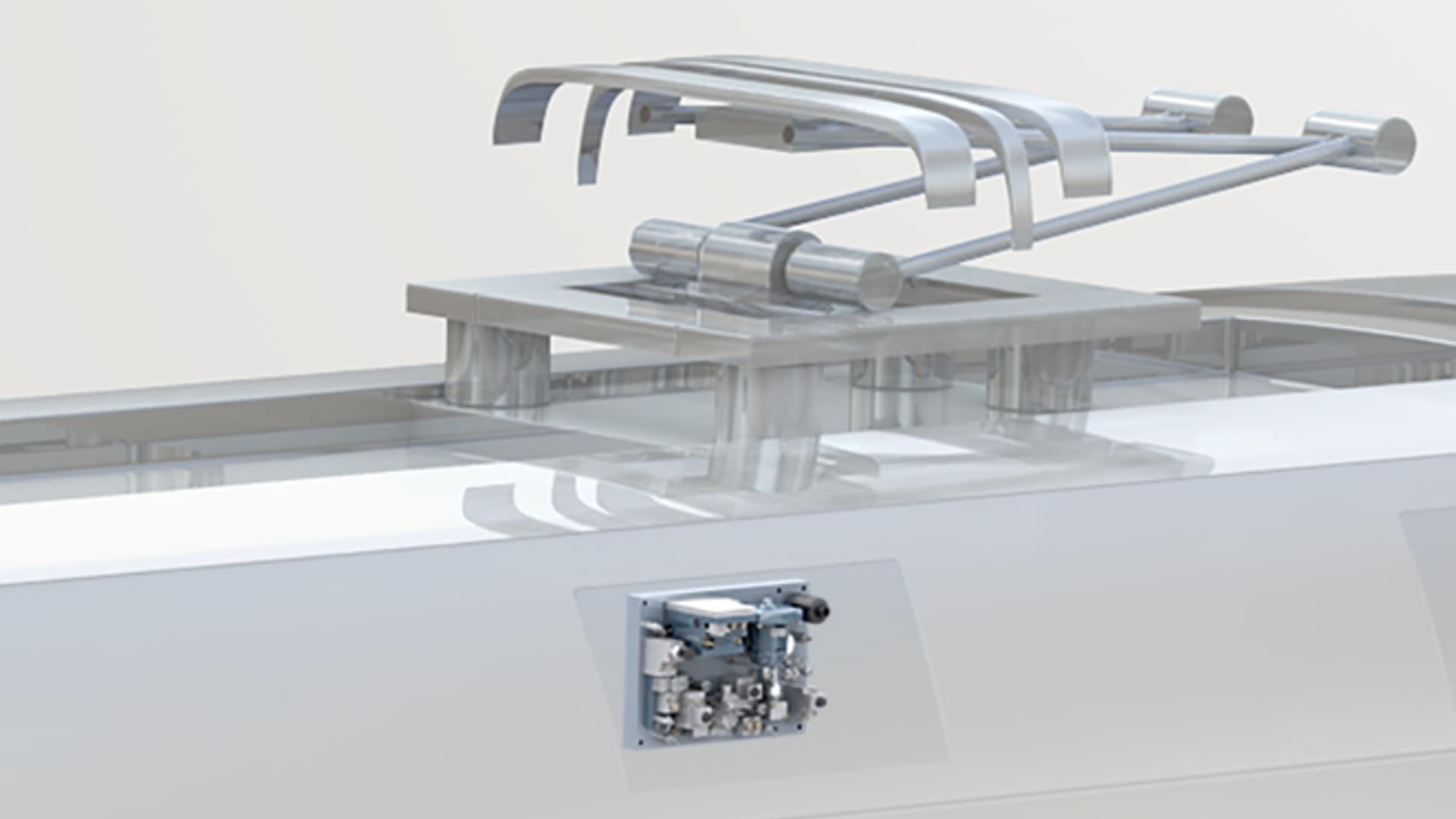

Take a look at the complete range of systems for rail vehicles, from the individual product to intelligent system solutions.

Read more