Reducing the weight and noise emissions of rail vehicles is becoming an increasingly high priority. Here, AirSupply Smart is setting new standards. Thanks to intelligent, adaptive functionality and a compressor design with a sound profile optimized using innovative development methods, Knorr-Bremse has been able to achieve noise emission targets previously unattainable by a non-soundproofed piston compressor.

Contact

80809 München

Deutschland - Germany

carina.smid@knorr-bremse.com

Frequency inverter paves way for adaptive control system, reducing both weight and noise emissions

A paradigm shift is currently taking place in the field of air supplies for rail vehicles – driven by AirSupply Smart. What was previously a component that always operated in simple stop-start mode has been transformed into an intelligent system with a frequency inverter that acts as both its main power supply and control unit. For the first time, the inverter makes it possible to manage speed – and therefore power – independently of the train’s own power supply. To achieve this, AirSupply Smart combines several functions in a single, multifunctional unit, simplifying the system as a whole and achieving a wide variety of benefits thanks to an adaptive control system.“Boost Mode” is a good example. If there is a sudden high demand for air, the frequency inverter can increase the compressor’s operating speed and reduce train setup times by boosting the rate of delivery. In critical situations, this has an immediate impact on the operational quality of the entire mass transit network. When, for example, a large number of passengers disembark simultaneously at a central transit hub, causing the air suspension to consume large quantities of air, the boosted airflow reduces the time required to prepare the vehicle for departure. And thanks to Boost Mode, in many cases trains will be able to use smaller compressors without compromising the reliability of the air supply.

In turn, this “downsizing” not only helps to reduce weight and installation space, it also helps to substantially reduce noise emissions: A smaller compressor essentially means less noise pollution. Furthermore, this approach has ecological benefits: with less mass to accelerate, trains consume less energy. And if they emit less noise, environmental noise pollution also falls. Yet another benefit lies in the fact that the size of the compressor is no longer determined by peak demand; instead, the main criterion is that the compressor should run optimally in normal (non-boosted) operation.“Silent Mode” is another benefit associated with the adaptive control system. By deliberately reducing the compressor’s operating speed whenever less air is required, noise emissions can also be reduced. This mode helps rail operators to comply with increasingly stringent noise regulations and protect areas of particular environmental sensitivity – at night, for example, when trains are parked near residential areas or in stations. The positive impact of Silent Mode is impressive, as shown by the example of the VV120T compressor: By adjusting its operating speed based on demand, it can cut noise emissions by up to 75 percent. Thanks to this ability to regulate its operating speed, AirSupply Smart is able to reconcile various conflicting goals that were previously very difficult to resolve: delivery rate, soundproofing, and the flow of cooling air within the compressor. If the system produces less noise, soundproofing encapsulation can be reduced. And if less soundproofing is required, it becomes possible to simplify the cooling concept, which in turn reduces the complexity of the air supply system.But operating speed management is not the only thing that makes the overall package so attractive. The frequency inverter also delivers significant benefits when integrating the unit into the system as a whole. For a rail vehicle’s electrical engineers, compressors are complex components. Their rotational irregularities and high starting currents place significant strain on the train’s 3-phase power supply. The vehicle’s auxiliary power converter must be capable of providing the necessary reserve power and is consequently oversized. And in terms of energy management, it is important to ensure that the onboard power supply is not overloaded by the simultaneous startup of several compressors. All these issues are associated with corresponding labor and cost overheads. The smart solution: The unit’s frequency inverter buffers the starting currents and is also capable of directly processing the auxiliary power converter’s DC voltage. This completely eliminates the compressor as a 3-phase consumer – and the concomitant elimination of the auxiliary converter’s inverter stages makes the latter more energy-efficient.“Pantograph Mode” is yet another feature that has a direct impact on the complexity of the vehicle’s systems. Many electrically powered vehicles are equipped with a battery-powered auxiliary air compressor in addition to the “main” air compressor, so that pantographs can be raised even when the vehicle is depressurized. In “Pantograph Mode”, the frequency inverter converts the direct current from the vehicle’s battery into three-phase (AC) current and operates the compressor with a reduced starting current, at lower speed. The resulting drop in the power required makes it possible to run the “main” air compressor from the vehicle’s 110-volt battery for short periods of time without overloading the battery. Once the pantograph makes contact with the overhead line, the control system switches back into conventional recharging mode. This removes the need for a second, auxiliary air compressor – the entire assembly becomes superfluous, with all the resulting benefits in terms of space, weight and maintenance costs.

Among the concept’s other strengths are innovative digital features. Designed from the ground up as a sophisticated platform, the frequency inverter has the interfaces required to add new functions via software updates. A condition monitoring package already keeps an eye on essential system functions and reports any functional impairments. Early fault detection, avoidance of major secondary faults, and reduction of maintenance and repair overheads are just some of the benefits that have a positive impact on the unit’s operating costs. The new air supply is also capable of processing data from up to eight additional sensors, even for demanding diagnostic activities such as monitoring oil or moisture levels.The synergistic effects are also noteworthy, because the system can use existing rail-vehicle electronics for monitoring purposes – no need for additional interfaces or housings, and no need for additional hardware validation such as EMC tests for electromagnetic compatibility, or shock and vibration tests.Another example of the system’s flexible, modular support for functional expansion is the electrically controlled fan used in the latest generation of Knorr-Bremse compressors. In conventional systems, the fan is rigidly mounted on the shaft. The electric fan, on the other hand, is managed directly by the inverter, with no additional control electronics. The necessary inputs and outputs are all part of the package, meaning that the control software is also easy to install.From an ecological perspective, the adaptive ability to adjust to different operating conditions and compressor performance requirements has significant benefits in terms of the air supply system’s weight and noise emissions, as well as reduced complexity, consumption of materials, installation space and life cycle costs.

Smart development methods pave the way for noise-optimized compressors

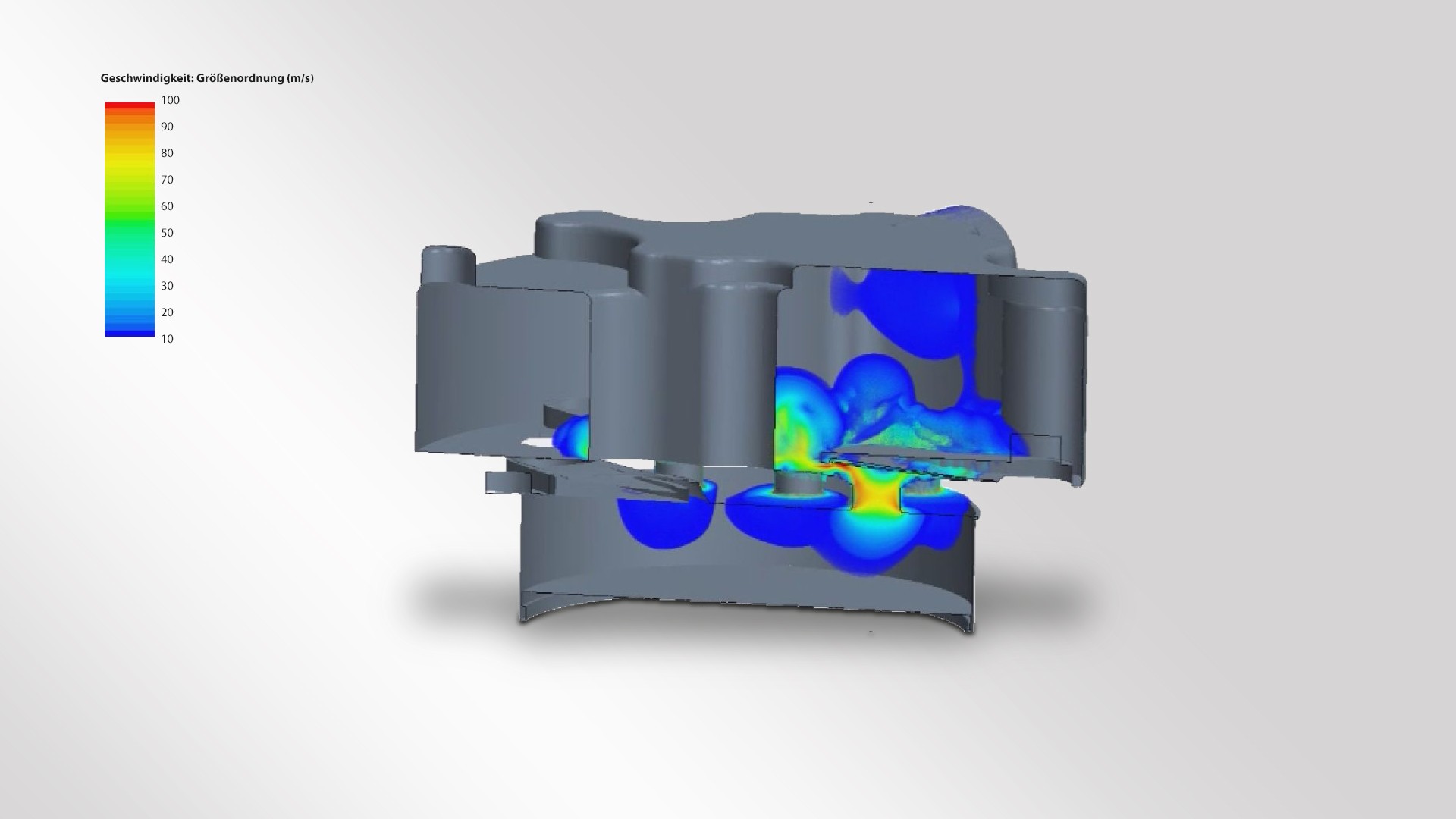

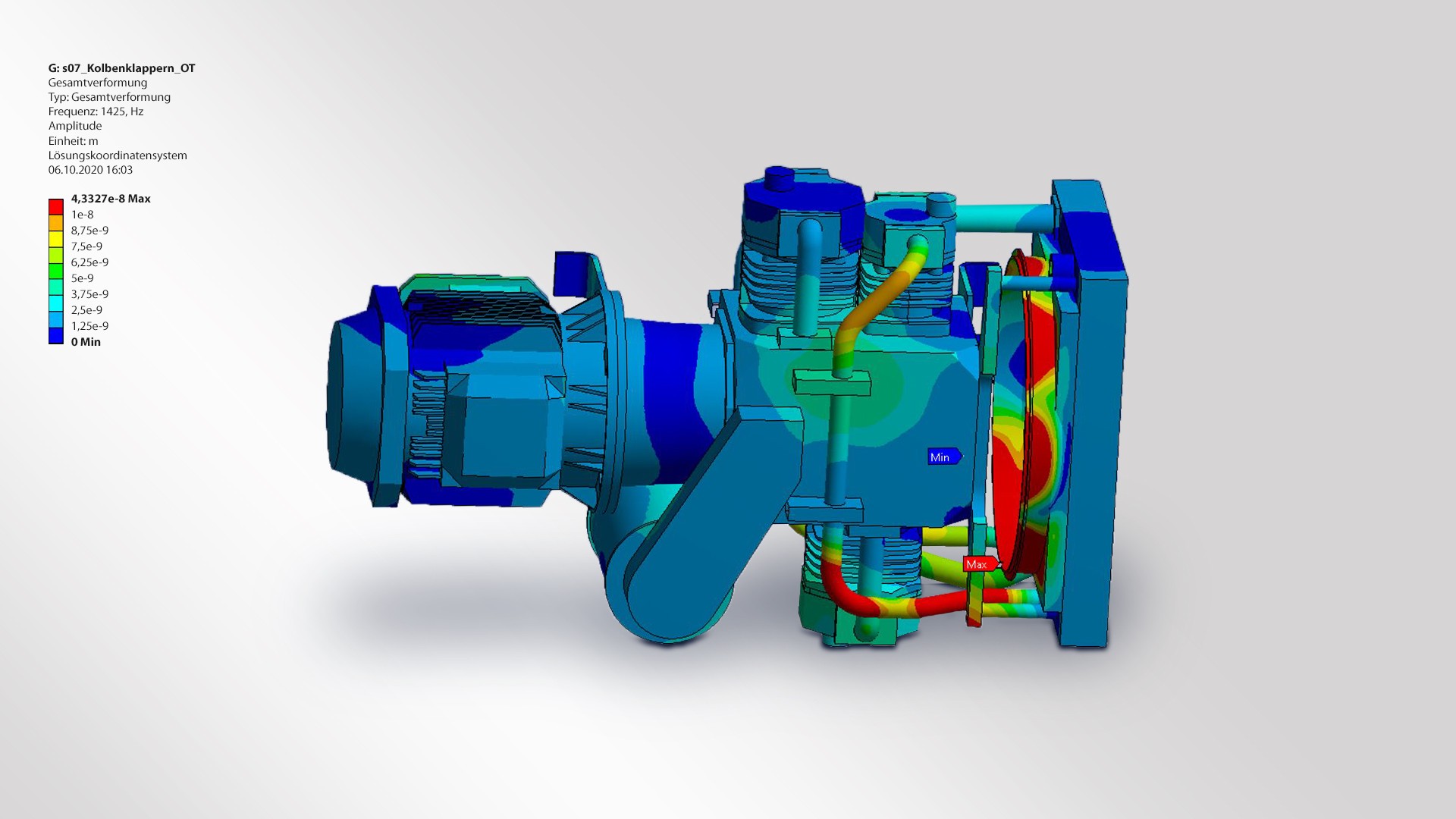

Today’s projects sometimes require extremely low noise levels that cannot be achieved even by the mighty tool of “Silent Mode” or situational speed reduction. To meet such rigorous noise emission specifications, the compressor must be further optimized, over and above its already sophisticated functionality. By making clever improvements to noise-emitting compressor components such as valves, pistons, bearings and filters, structure-borne noise and noise pollution can be further reduced both in and out of Silent Mode. The phenomena involved are complex, however, and characterized by interdependencies. What operating conditions cause which components to emit specific sound-wave components? When conventional acoustic measurements are used, the limits of this analytical method are swiftly revealed – which is why Knorr-Bremse’s engineers are taking a new approach. The first step is to accurately identify all sound-generating components. By combining multiple simulation methods such as modal analyses, harmonic analyses, explicit structural simulations and flow simulations, it is possible to efficiently identify the relevant sources of sound waves. It is instructive to view the VV120T through a “virtual” acoustic camera: Part of the critical sound is emitted by a filter valve, a small component just four centimeters long and weighing just 20 grams. When agitated in operation, the component acts like a tuning fork, radiating sound over the compressor’s surface. A more detailed analysis of these acoustic emissions

The next step is to define and test optimization approaches. In this case, mere attempts to make improvements at the level of individual components will not be enough, because optimizing one area can cause deterioration in three other areas. Smarter methods are required, such as modal analyses based on the finite-element method (FEM).These offer an alternative – and above all, practical – option for simulating the values of the natural frequencies of sound-emitting components by using their CAD (Computer Aided Design) data. To determine their – equally important – vibration amplitudes, it is once again necessary to carry out explicit FEM simulations to extract the amplitudes over time. Once these have been transformed into a frequency range, it becomes possible to quantitatively agitate the modal model. In this way, various modifications and their impacts on noise emissions can be simulated and virtually tested. The third step is to design and validate the most efficient way to optimize them. Returning to the example of the filter valve: The result, in the form of the Silent Valve System (SVS), damps the impact of the valve vanes on the valve itself; a solution which must now undergo an obligatory hardware test for final validation. A similar approach is taken to optimizing the design of other noise-influencing components such as fan cowlings or piston rings – and so, step by step, the air supply system’s noise emissions are minimized.By combining adaptive speed management with compressor optimization, the engineering team was able to ensure that the AirSupply Smart VV90-T is the quietest piston compressor in this size range ever launched by Knorr-Bremse that does not require complex soundproofing encapsulation. To the human ear, a conventional compressor of comparable performance is twice as loud as the AirSupply Smart VV90-T in “Silent Mode”.

Conclusion

These results show that the potential for reducing the emissions associated with air supply systems for rail vehicles has not yet been exhausted; there is still room for innovations that further improve sustainability and reduce noise. Even so, thanks to its adaptive control system and the use of effective development techniques, the AirSupply Smart VV90-T has been able to position itself as the quietest piston compressor without soundproofing encapsulation ever supplied by Knorr-Bremse in this output range.

Authors: Dr. Martin Schmid; Martin Schmid; Ludwig Obermaier