Urbanisation and new requirements for efficient and highly flexible local transport call for innovative solutions. Against this background, the Knorr-Bremse subsidiary IFE is expanding its portfolio of entrance systems with the LIFEDrive linear motor (Linear motor IFE Drive). For the first time, this product allows two door leaves to be driven independently of each other, offering enormous advantages especially when it comes to tight underground railway schedules.

Contact

3331 Kematen/Ybbs

Österreich - Austria

ingo.wild@ife-doors.com

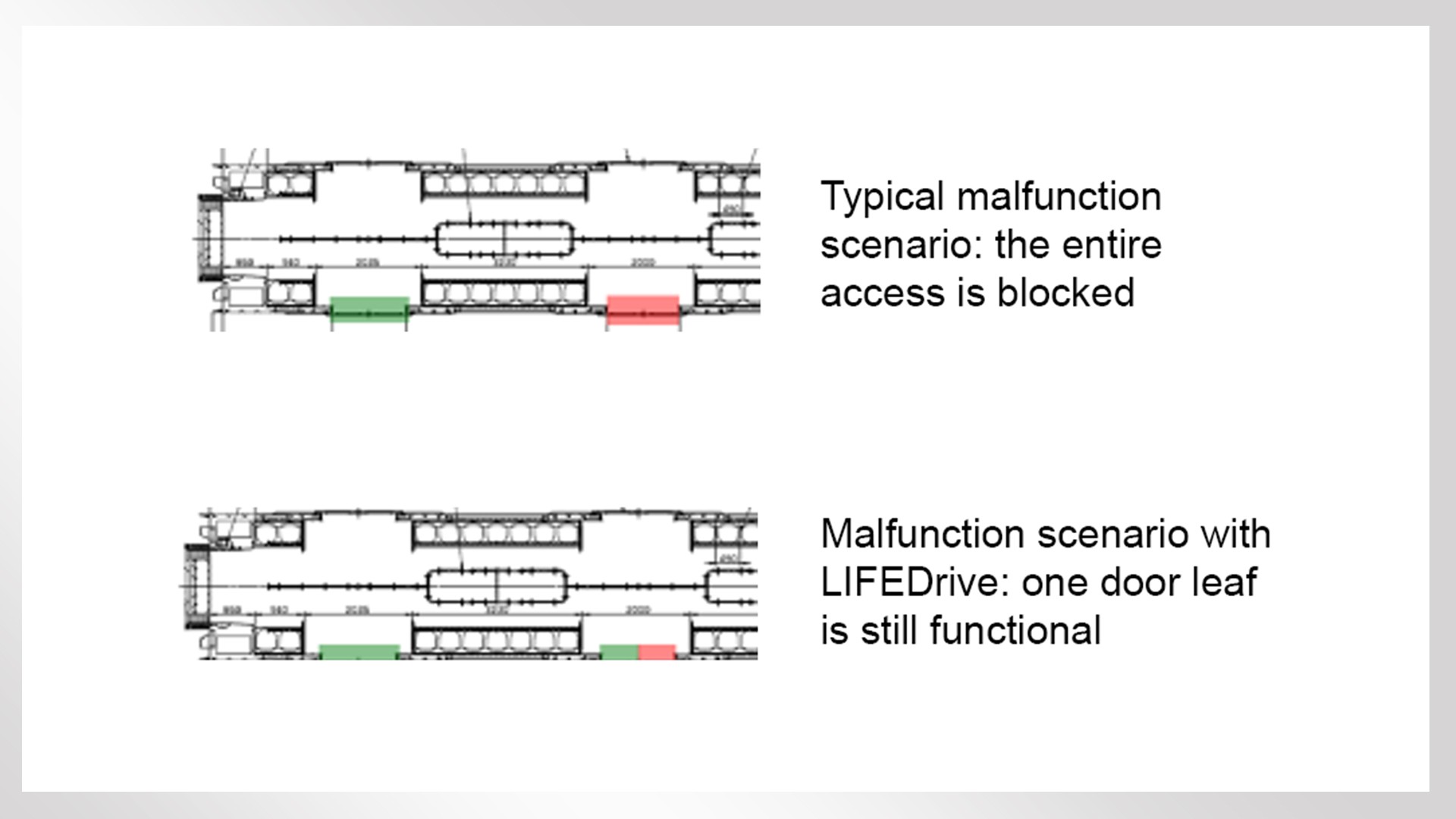

Even if passenger numbers are currently lower than before Corona period, the need for rail mobility – keyword climate change – will see increases worldwide in the long term. Fast and efficient boarding and deboarding therefore play a central role in handling large numbers of passengers – and thus also in avoiding technical bottlenecks. For example, a scenario where a train door suddenly becomes blocked can have serious consequences for smooth operations. “On the platform, passengers then have to move to the nearest boarding point, and in the vehicle they have to walk through the crowds in the central aisle to the next exit – which is then often used as the boarding point from the platform,” says Hans Gold, head of IFE's ‘Urban’ business segment, describing the problem.

In the case of a high-speed train, whose timetable already includes a platform stop of several minutes, the scenario can be disregarded to a large degree. But on a tight underground railway schedule during rush hour with train headways of 2-3 minutes or less, the situation looks very different. If a train is blocking the tracks in a station, the following train is also not able to enter. The risk of the so-called accordion effect increases considerably – a scenario familiar to motorists that involves a flow of traffic that seemingly stalls on its own due to constant acceleration and deceleration – compromising the scheduling.

Ready to depart after 37 seconds instead of 60

The new IFE linear motor drive addresses the root of the problem, the door – which is possibly only blocked due to a defective limit switch. Instead of the conventional set-up of driving two coupled door leaves together, the LIFEDrive controls the two door leaves separately. “If it becomes necessary, passengers can enter and exit through the remaining door leaf,” Gold explains. Although the process would then be somewhat slower, this would make the time-consuming paths to the next door or through the central aisle unnecessary. If worst comes to worst, this saves valuable time – and helps to ensure the reliability and dependability of the timetable.

In order to be able to quantify the effect, IFE and Metro Delhi started a pilot project. To do this, they sent a metro with appropriately modified boarding systems into the field and lengthened the stop time, i.e. the total time for boarding and deboarding, using either one or two open door leaves. If one of the two door leaves could still be operated, the duration of the boarding and deboarding time was around 40 percent lower than with two blocked door leaves. Instead of 60 seconds, the train was ready to depart after only 37 seconds.

Optimised timing at rush hour

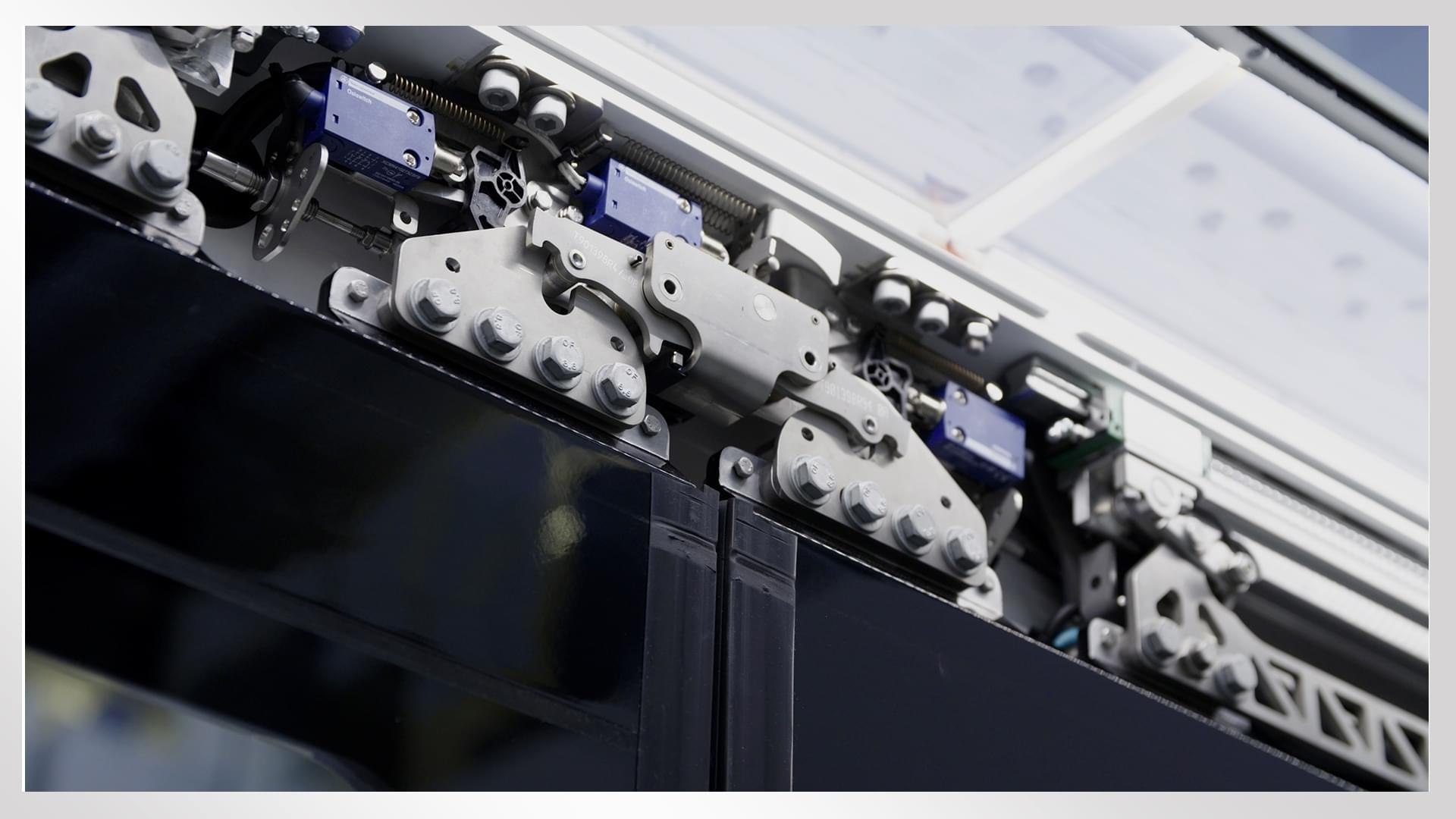

Inconvenient malfunctions should be extremely rare, however, because the LIFEDrive is also notable for its particularly high availability and reliability. In all test series, significantly fewer critical errors occurred than with comparable systems. In daily operations, the fast opening and closing times of 2.5 s (+/- 0.5 s) with a double-leaved entrance width of 1,400 mm are impressive. Entrance widths of up to 800 mm for single-leaf and up to 1,600 mm for double-leaf boarding also make it easier for passengers to change trains, especially during the usual rush hour traffic on metros, allowing opera-tors to optimise timetables on busy lines.

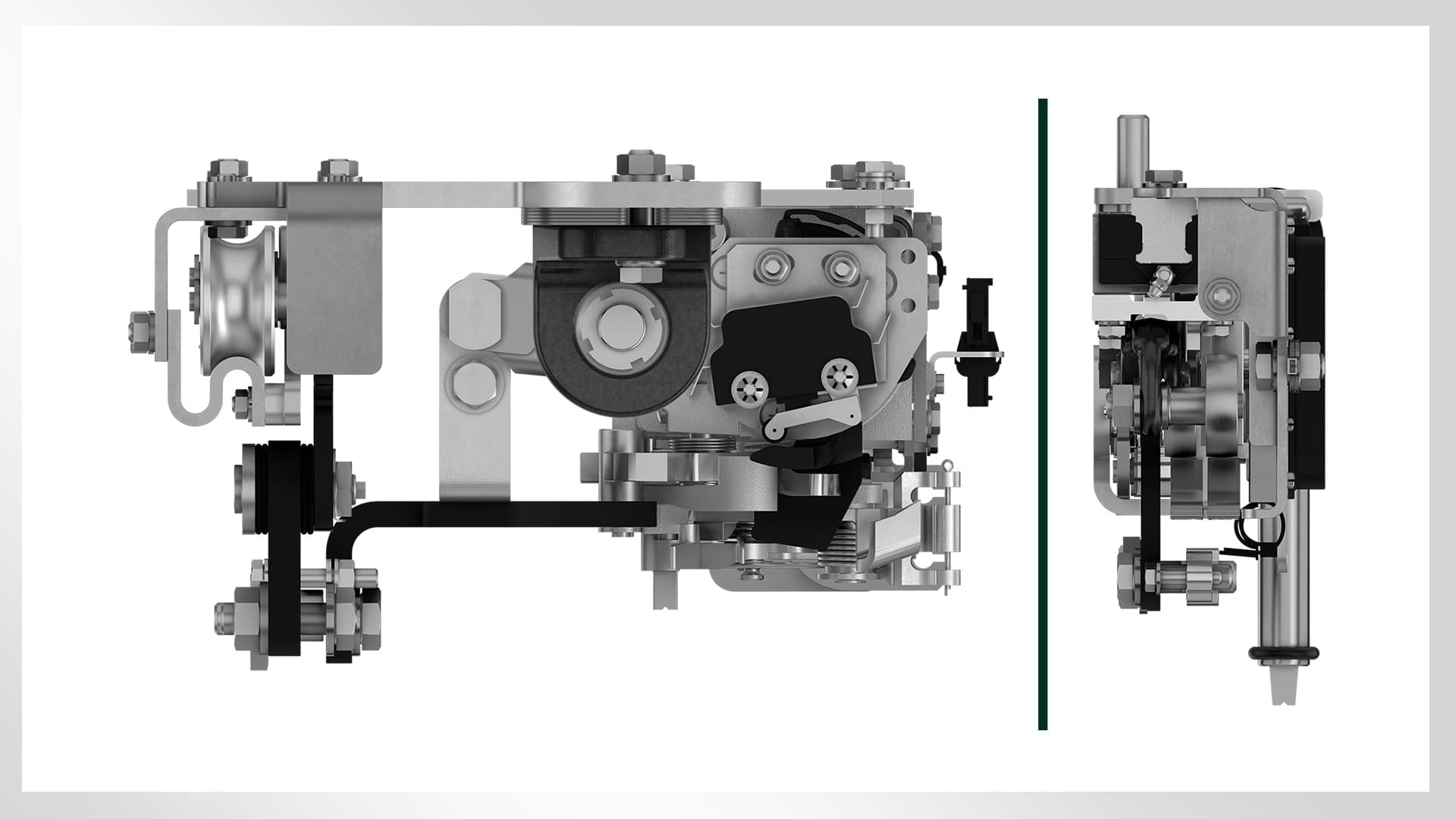

Customisable modular design

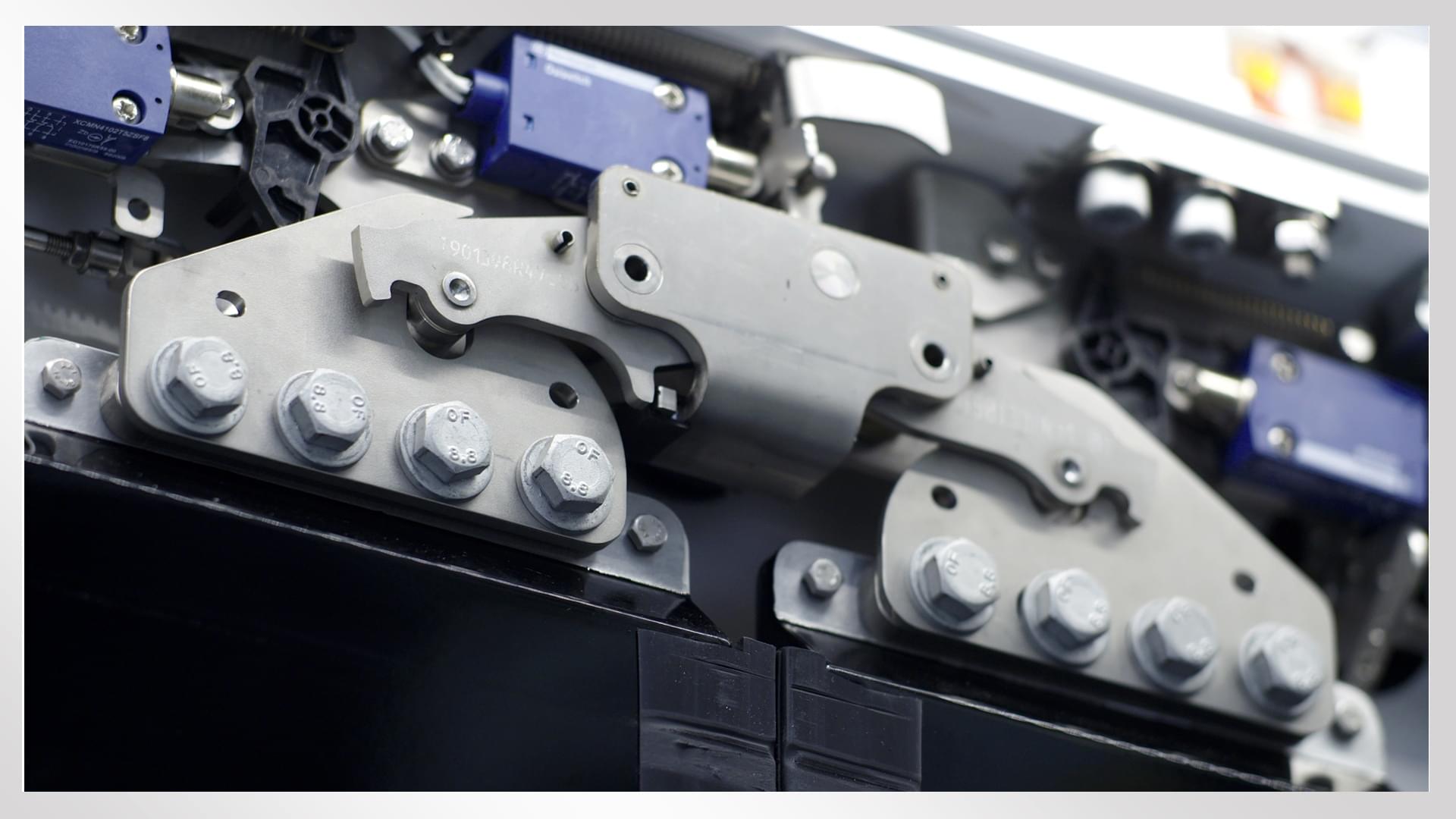

“The LIFEDrive is the most modern sliding door on the market,” according to Oliver Schmidt, Chairman of the Executive Board of Knorr-Bremse GmbH in Austria and responsible for IFE's worldwide door business, classification of the new drive. “However, it is not to be seen as a competitor to the existing portfolio. Rather, this system is allowing us to expand our range.” Developed for use in the underground, the LIFEDrive contains a number of adapted, proven, and maintenance-free components.

A circumstance that is also reflected in the low life cycle costs: “Compared to conventional systems and calculated over 30 years, we can reduce these costs by about 30 percent by using the LIFEDrive,” says Schmidt. In addition, the system can also be adapted to specific customer requirements, for example in terms of entrance widths or the optionally available SmartSlide function for improved acoustic insulation. To increase passenger safety, the door drive can also be equipped with anti-drag & push-back functionality. These are features that prevent passengers from getting trapped in the doors.

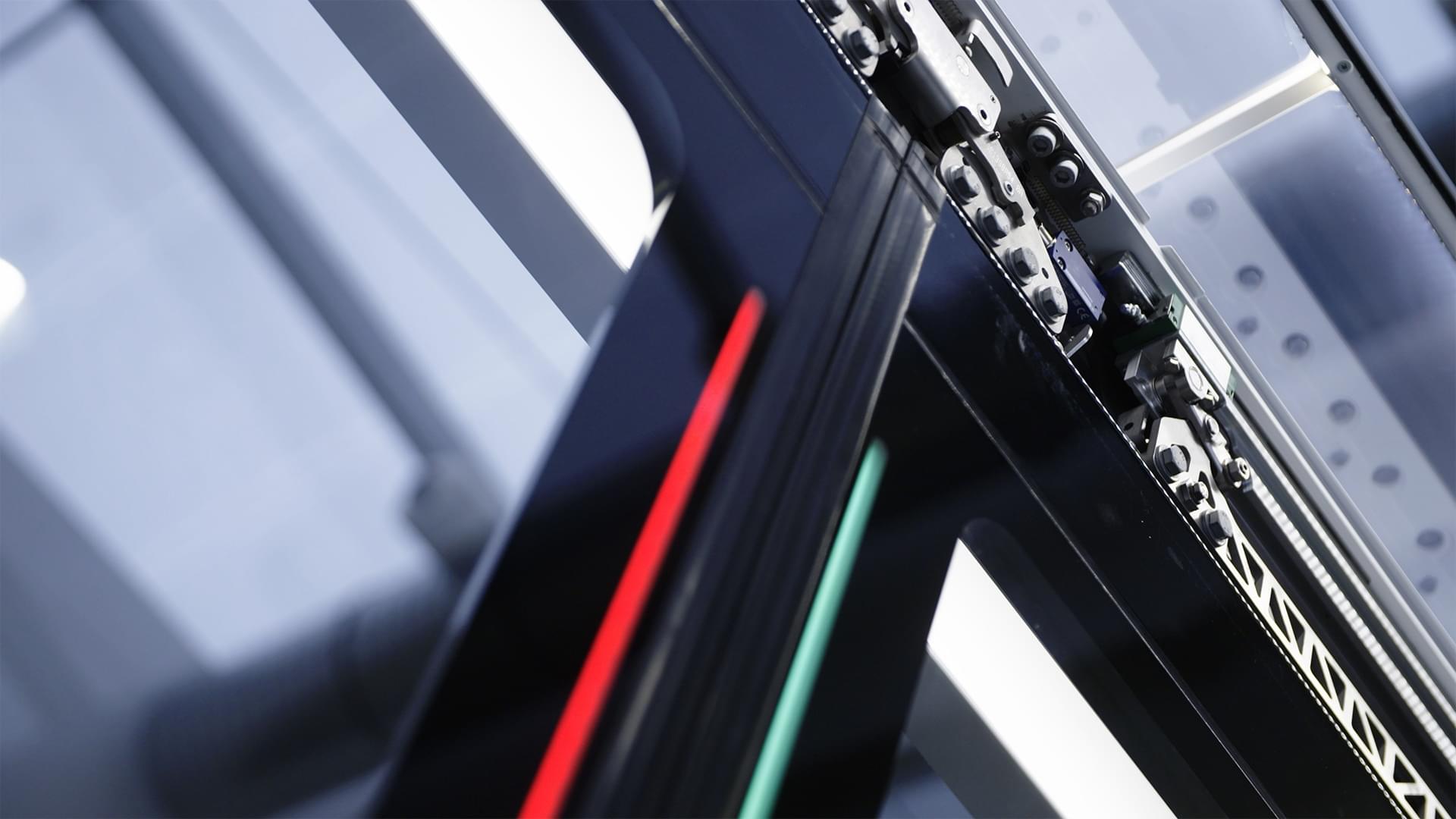

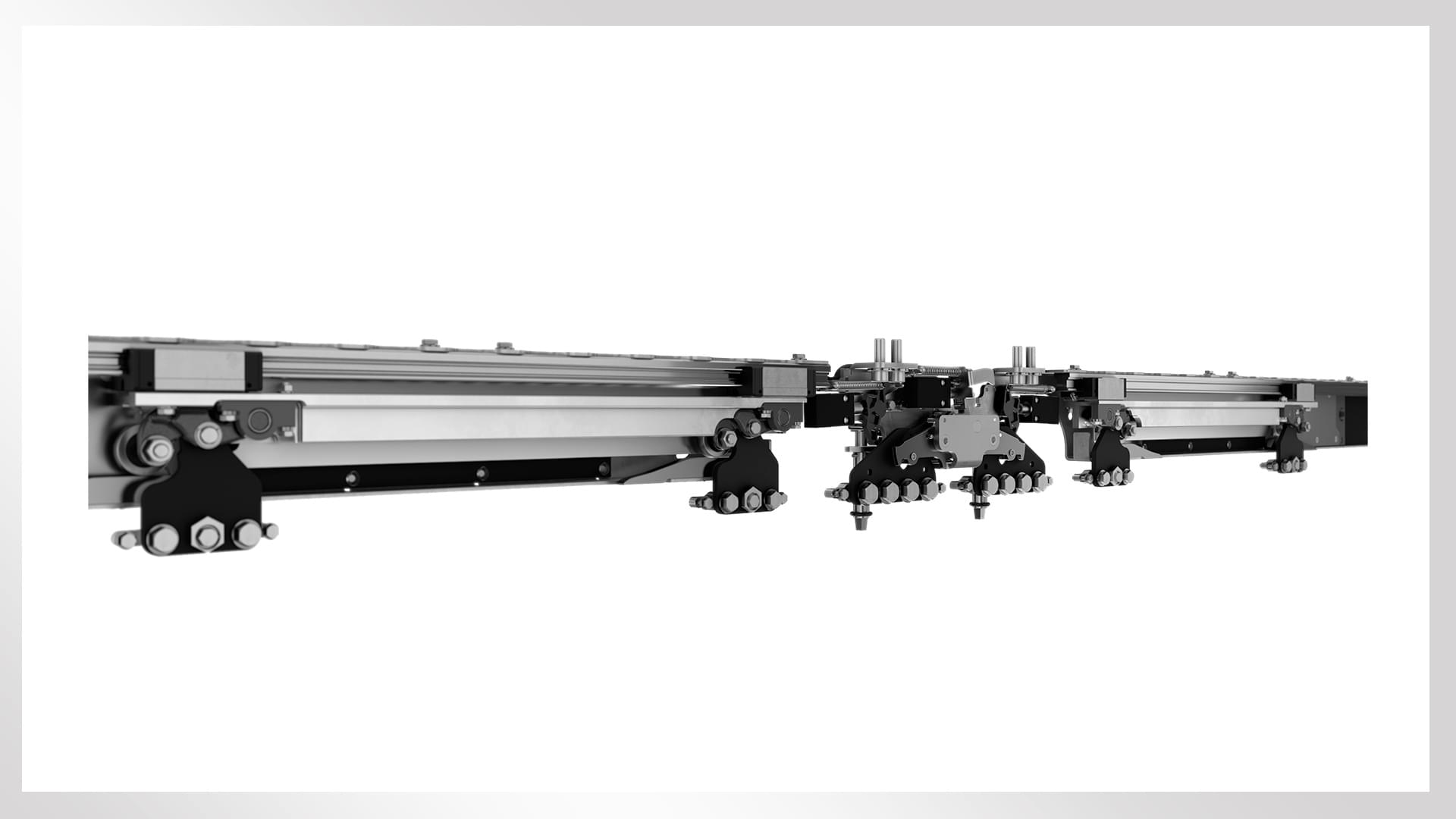

Smallest & lightest drive

LIFEDrive has another decisive advantage: its extremely narrow installation space. For the first time, the door drive of an exterior sliding door can be installed completely outside of the car body. This design allows for greater flexibility in the interior and creates space for passenger displays, for example. The advantage is best described by the reduced cross-sectional area of the drive. Compared with other common sliding doors, this has been reduced from 113 cm² to 77 cm², i.e. by 32 per cent. A relatively small component – but with a significant effect when it comes to creating available urban mobility.

LIFEDrive - the technical data

- Available as an external and pocket sliding door

- Smallest (70 x 110 mm cross-section) and lightest (35 kg) door drive on the market

- Use in driving operation up to 120 km/h

- Single-leaf entrance width: 650 to 800 mm

- Double-leaf entrance width: 1,300 to 1,600 mm

- Individual door drives for independent opening & closing

- Fast opening and closing cycles: 2.5s (+/- 0.5s) with a double-leaf entrance width of 1,400 mm

- High availability and reliability

- Lowest LCC and maintenance

Videos

Data transmission to YouTube

This video is embedded on our website via YouTube.

Data is only transmitted to YouTube when you click on “Agree”.

Please refer to the privacy policy of YouTube for more details.

More Information