Designing, testing and validating rail vehicle braking systems is a complex business for all concerned, including developers, certification agencies and operators. Freely available to everyone, the Train Brake Calculation (TrainBraC) program provides valuable assistance throughout the process and has become established as the rail industry standard for performing braking calculations and verifying in-house computations. Ten years after the program was first rolled out, it has just received a comprehensive upgrade: TrainBraC Next Generation.

Efficient tool demystifies increasingly complex process of designing and validating braking systems

Back in 2002, when Knorr-Bremse Systeme für Schienenfahrzeuge GmbH, Siemens Mobility GmbH and DB Systemtechnik GmbH first decided to join forces and develop TrainBraC, the entire rail industry was still using a wide variety of proprietary brake calculation programs. The industry’s future needs were already exposing the weaknesses of existing calculation tools, with their widespread use of empirical defaults and mean values. At the same time, new vehicle developments were being commissioned at a time of profound transformation, just as the liberalization of the rail market was starting to take hold. National guidelines were being replaced by international ones (EN14531), and standardization projects were the order of the day.

A new tool was needed to handle the many different dependencies and parameters such as time, speed and load level, and to enable the development of complex, physical vehicle configurations that take due account of braking technology. The programmers also wanted to make it as easy as possible to share design calculations both internally and externally – within companies, between project partners or certification authorities, and across multidisciplinary teams engaged in research and development. Last but by no means least, it was also important to significantly improve both efficiency and error mitigation in the braking system design process. The development of TrainBraC, with its modular program structures, promised to achieve all these objectives. As a result, a cross-company, multinational team was assembled under the leadership of Knorr-Bremse Systeme für Schienenfahrzeuge GmbH.

Contact

80809 München

Deutschland - Germany

carina.smid@knorr-bremse.com

TrainBraC as integrated calculation program for technical brake certification

Since 2012, the tool has provided essential support for designers of efficient, reliable braking system designs intended for individual and platform vehicle development projects in the mainline rail, LRV and metro markets. Instead of working with multiple “dedicated programs” for system design, certification preparation and operational verification, designers can now use TrainBraC, which bundles all these functions together in a single coherent, integrated calculation program.

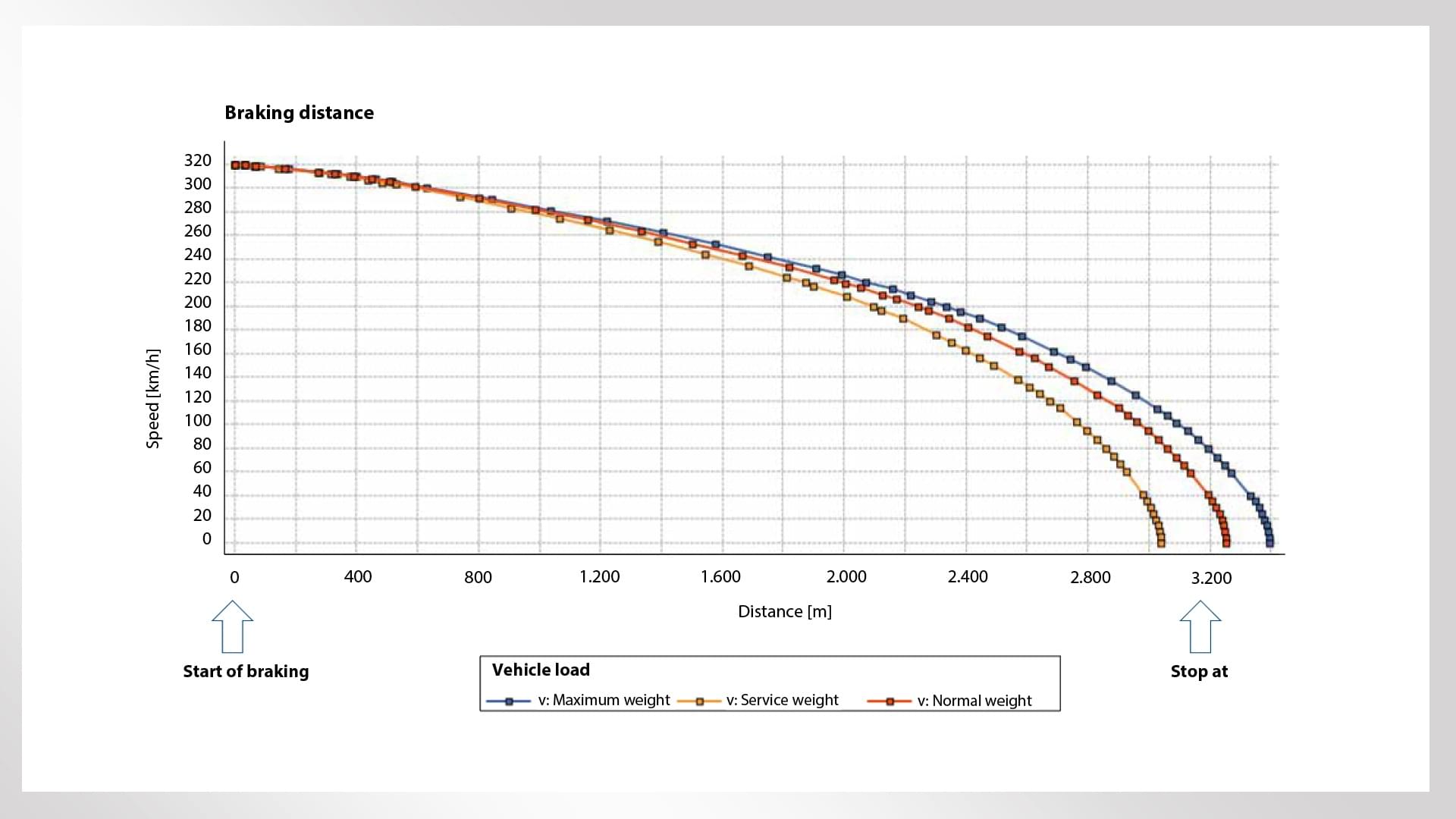

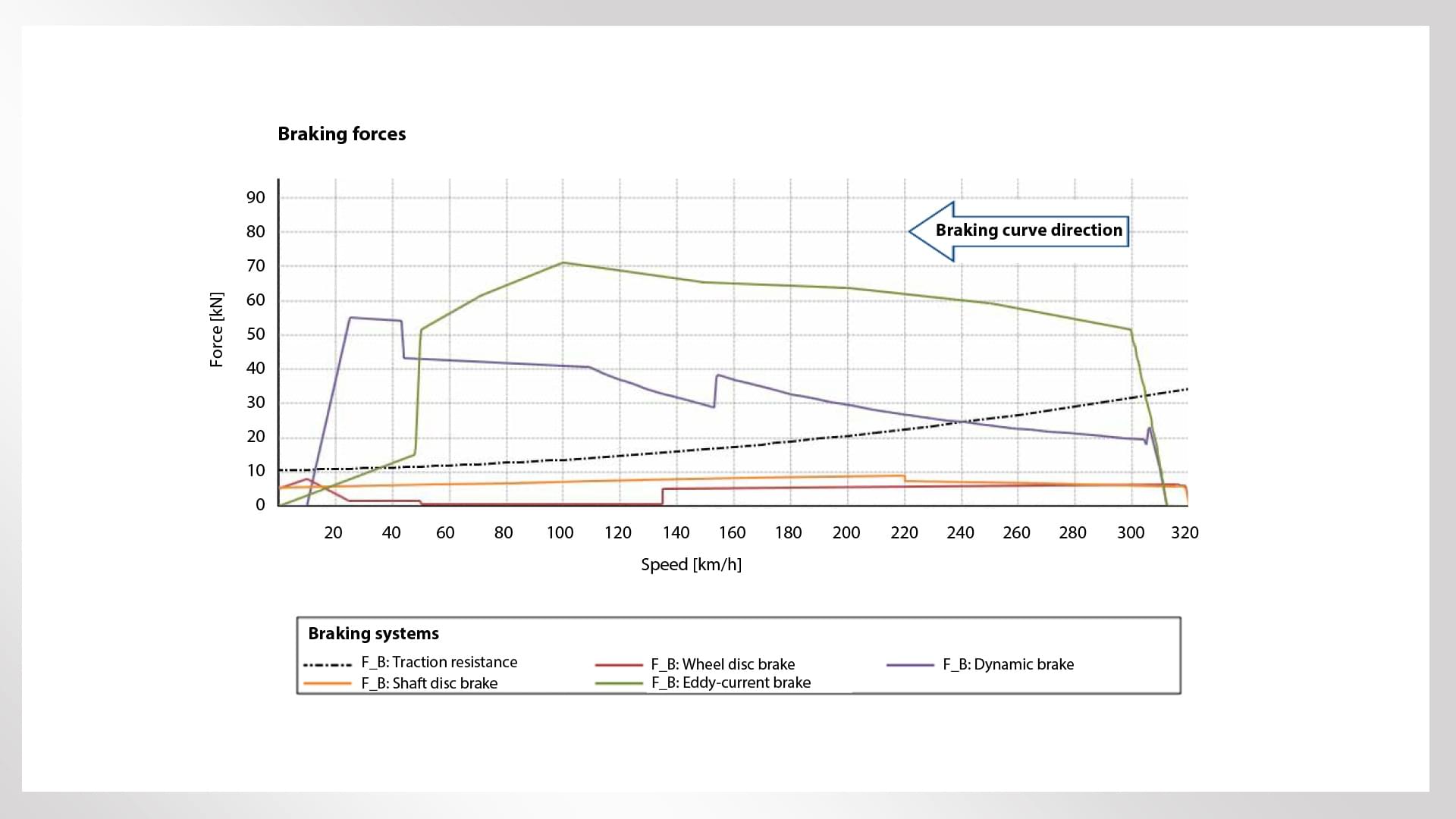

The value added by the tool is especially evident when designing modern multiple-unit concepts involving complex braking force distribution vectors and blending strategies – typically, in projects where braking should result in as little wear as possible and as much braking energy as possible should also be recuperated for supply to other vehicles in the mobility network. The developers also ensured that the results of the calculations required by the LOC&PAS TSI satisfy braking certification test criteria. At the same time, the system is capable of drawing comparisons between calculated and measured braking curves.

Further development based on proven software architecture

More than ten years after it was first rolled out, TrainBraC has now been given a comprehensive makeover that builds on the tried-and-tested architecture at its core:

- Standards-compliant calculation methods for mapping and analyzing braking processes based on a single-mass equation of motion with a punctiform vehicle mass model

- Time-step integration method for analyzing the prevailing physical values at each discrete moment in time

- Calculation of vehicle behavior over the full range of operating conditions and triggered braking actions (e.g. service, high-speed and emergency braking, including failure scenarios)

- Inclusion of an extensive set of different braking systems, together with their inherent properties and characteristics, implemented as dynamic-link libraries (DLLs) at operating-system level

The reasons for retaining this approach are as relevant today as they were when the tool was first developed. The rail industry as a whole benefits from greater efficiency in vehicle dimensioning, as well as the standardized data exchange of basis values and results. The lives of users working for the various players involved in vehicle development (vehicle manufacturers, operators, supervisory authorities, etc.) are made easier by the tool’s facilitation of time-consuming, highly repetitive activities.

Tool’s further development introduces determining links between vehicle parts and braking system components

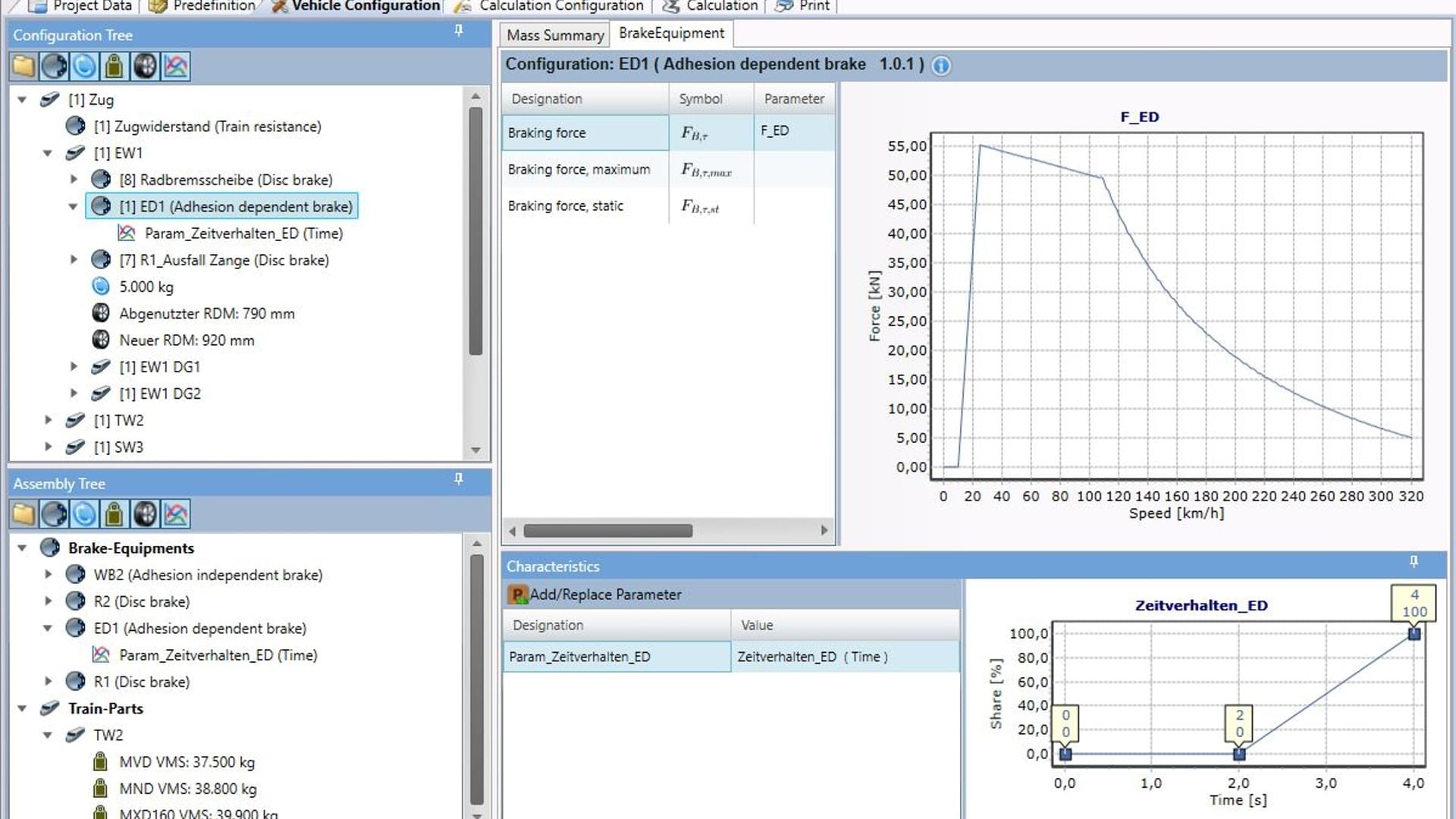

The more complex the computation, the more sense it makes to represent the vehicle structure as a (hierarchical) tree structure. This makes it possible to build a model of the vehicle broken down into its finest structural elements, right down to the individual wheel. There are no restrictions on the number of elements or levels of structure that can be depicted.

While the first version of the tool could only portray vehicle configurations in a hierarchical structure, TrainBraC Next Generation distinguishes between the vehicle configuration and the templates for individual vehicle parts. This approach adds particular value when tackling multi-car vehicles or vehicle platforms: Structural elements such as train parts, cars or bogies can be defined using the relevant braking system components, and these definitions can then be reapplied in a very user-friendly way.

Thanks to the simple, clear way in which vehicle parts and braking system components are linked to the vehicle configuration, brake setups can now be flexibly copied from one project to another using standard drag-and-drop techniques. Even better, users can make precise adjustments to individual parameters at any time. Users can also open and edit multiple projects simultaneously, and create variations based on different deceleration speeds. In addition, the use of identifiers for braking cases means that the system will soon be able to generate different print outputs for different audiences – e.g. internal or external – from the same master file. If necessary, the outputs can be digitally signed. The algorithms used are based on the EN14531 series of standards, and will be further developed as the standards themselves evolve. The program can also produce ISO 20138-compliant brake calculations.

Next evolutionary stages will include use-case contexts

In exactly the same way as the rail vehicle industry, rail vehicles and rail vehicle sub-systems continue to evolve as they keep pace with technological progress, the consortium plans to continue with the ongoing development of TrainBraC. Indeed, the inclusion of such future developments has already been anticipated in the software architecture, in the form of support for appropriate software containers that can be docked to the program (to generate e.g. ETCS, Monte Carlo or thermal simulations).

The freely downloadable demo version of TrainBraC helps users to understand existing calculations by providing insights into the structural, functional and analytical options available. To use the professional version of the tool, which includes the complete range of functions, users must purchase a license together with the appropriate training course. A read-only function is provided free of charge. Training courses can be ordered from the consortium via the www.trainbrac.de website.

Summary

Over many years of operational use, TrainBraC (the Train Brake Calculation program) has become established as the rail industry standard for performing physical calculations in braking scenarios. For more than ten years, rail vehicle developers have used it to efficiently design, analyze, test and validate the performance of braking systems. The latest version, TrainBraC Next Generation, is based on the same proven calculation methods and architecture as its predecessor, but adds a slew of new functions accessed through a redesigned, state-of-the-art user interface. To support the ongoing evolution of rail technology, the software is now ready for future modular extensions.

Authors: Ralf R. Schmid (Knorr-Bremse SfS), Toni Schiffers (Siemens Mobility GmbH), Marie-Christine Gobin (Siemens Mobility GmbH), Robert Karbstein (DB Systemtechnik GmbH)