The manufacturing of individual spare parts plays a key role in the maintenance and repair of rail vehicles. Here, precision and quality are crucial for ensuring that rail vehicles can continue to operate safely, reliably, and in full compliance with industry standards.

Our workshops perform a wide variety of material processing operations, including metal cutting, welding and grinding, CNC machining, 3D printing of obsolete parts, and painting. These operations are vital for repairing or replacing damaged parts, thus ensuring that train components comply with the necessary standards.

Whether we are replacing entire side walls or individual structural components, our experienced technicians carry out structural repairs with the utmost precision.

Contact

2450 Copenhagen

Danmark - Denmark

Material processing – main areas of activity

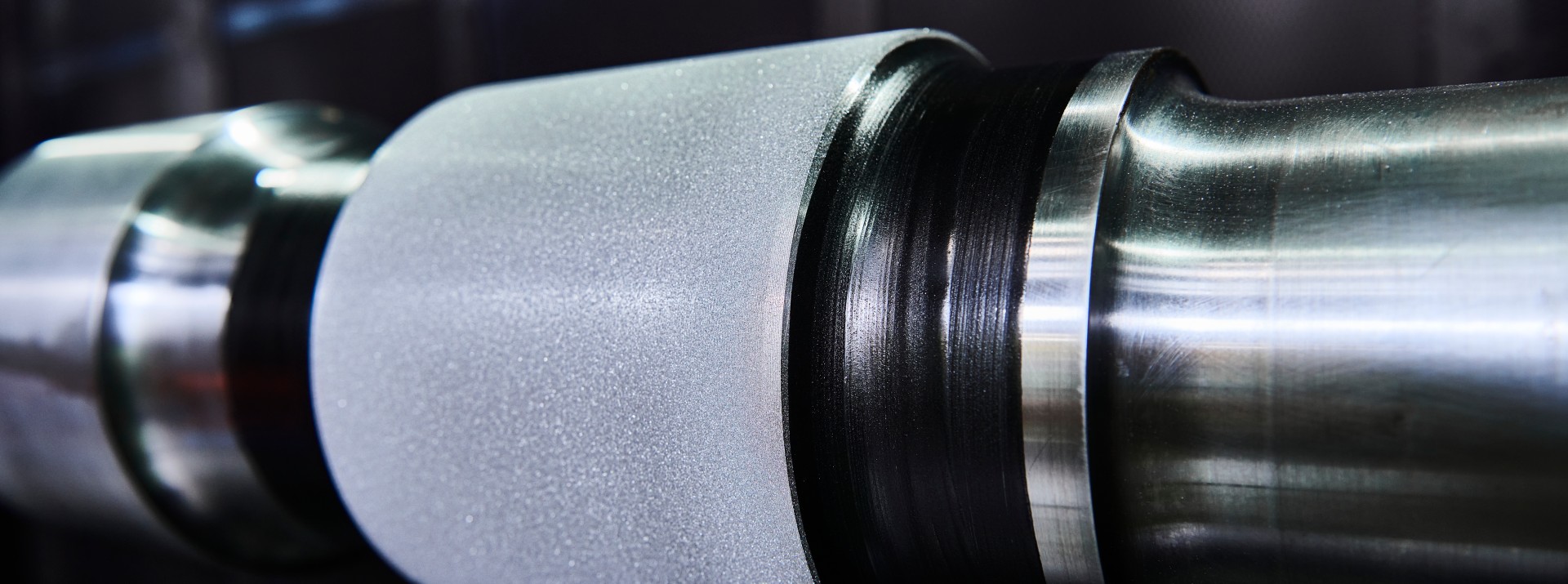

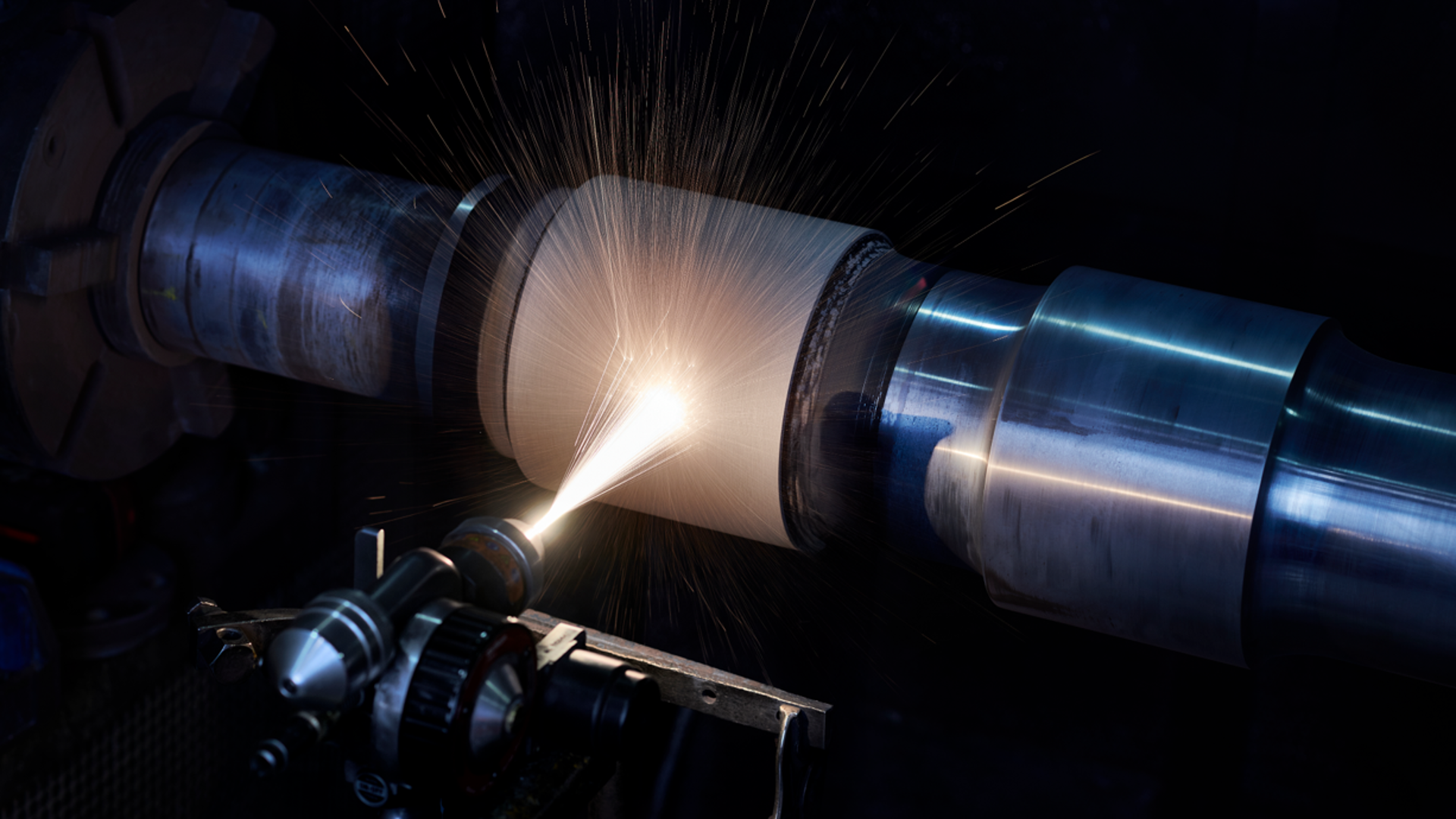

Thermal spraying

Using our thermal spraying techniques, we restore worn axles to their original specifications. We can restore components to their original specifications by the precise application of metal coatings, eliminating the need for complete axle replacement. Not only does this process extend the service life of components – it also helps to significantly reduce lifecycle costs and contributes to sustainable maintenance practices.

Welding

Our specialized welding services allow us to fully restore rail vehicles to their original condition. Whether replacing entire side panels or specific structural sections, our experienced technicians carry out structural repairs with exceptional precision. Thanks to our dedicated welding facilities and in-depth technical expertise, we reliably restore each vehicle’s structural integrity, boosting long-term fleet performance and operational safety.

Painting

Despite the many differences between mechanical components, most of them require a protective layer of paint to protect them from external wear and impacts. This work is carried out by specially trained personnel in our fully equipped paint shop. The scope of work ranges from small components and wheelsets to bogies and complete trainsets.

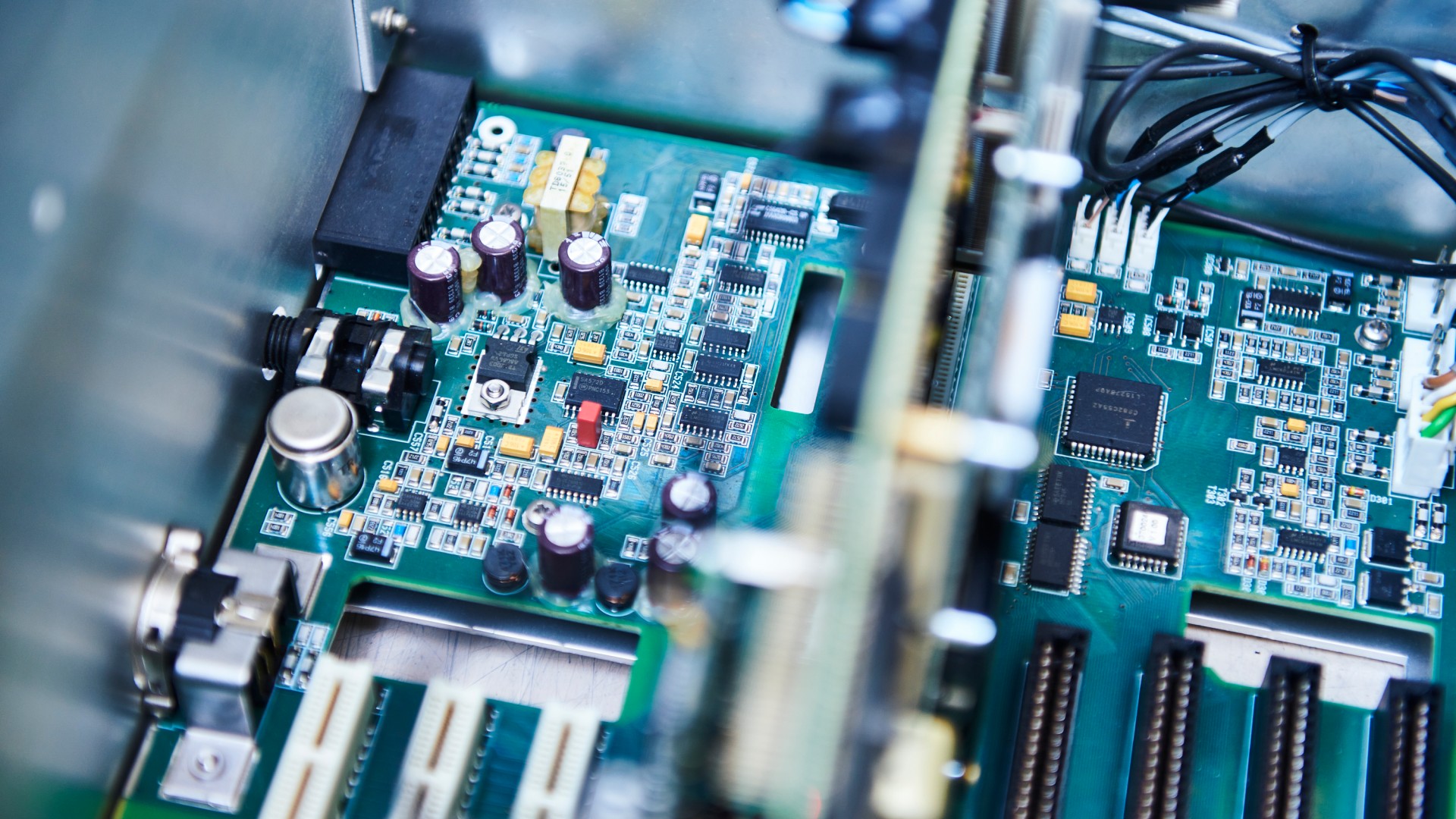

CNC machining

Our CNC workshop is equipped for high-precision machining processes and produces components to the tightest tolerances. Using CNC technology, we manufacture components for installation in the trains we overhaul on site, as well as for delivery to other Knorr-Bremse workshops across Denmark.

3D printing

We use 3D printing to produce selected rail vehicle components quickly and precisely. This technology allows us to manufacture small batches of customized parts that would be too costly to produce using conventional methods due to high setup costs. It is especially valuable for manufacturing obsolete or low-volume components, where traditional sourcing is no longer feasible or economically viable. By integrating 3D printing into our workflows, we gain additional flexibility in parts production and speed up turnaround times in critical repair processes.