With more than 30 years of operational experience, the Engineering team at Knorr-Bremse’s Component Services unit in Denmark provides expert support for heavy train maintenance. We are committed to understanding our customers’ needs and delivering effective, targeted solutions.

To ensure the efficient and effective maintenance of our customers’ rolling stock over its entire lifecycle, our engineering team provides comprehensive maintenance services plus intelligent support for asset management strategies. In addition, our team handles modernization projects to improve passenger comfort or ensure that your rail vehicles can continue to be used for passenger transportation. We tailor each solution to the specific requirements of our customers’ systems, developing customized components or reworking existing ones as necessary.

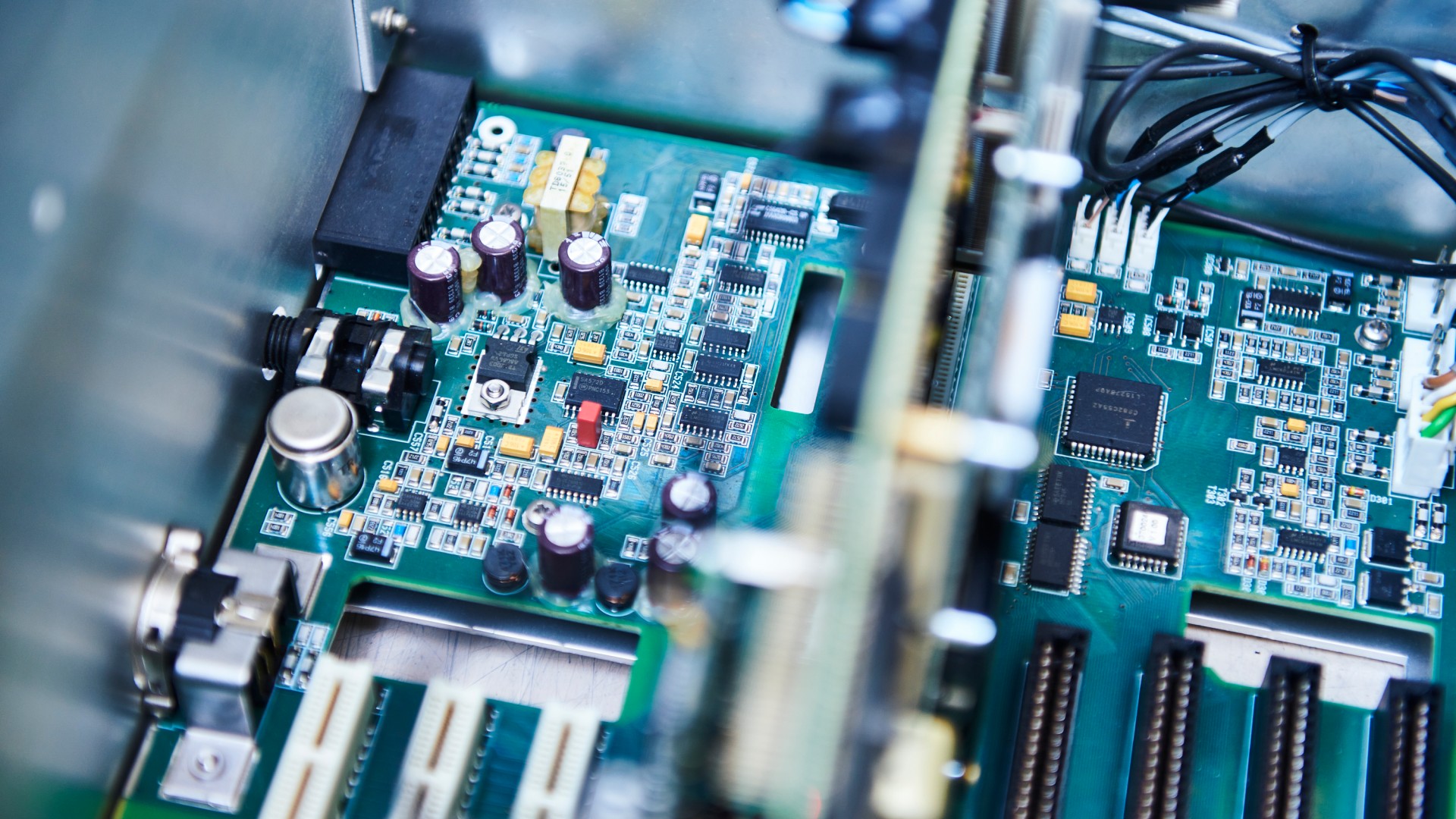

Our services cover the entire component lifecycle, offering comprehensive support at every stage. We conduct condition assessments of components, develop technical drawings and bills of materials, and prepare detailed supply and component specifications. Tailored solutions are provided for managing obsolescence and prolonging the service life of components. We carry out condition-based assessments and reverse engineering as needed to ensure continuing function and compatibility. In many cases, this approach supports the more sustainable use of existing resources. Our operations are fully compliant with EU regulations and industry standards, and we are certified under ECM F2.

Contact

2450 Copenhagen

Danmark - Denmark

Engineering services – main areas of activity

Maintenance optimization

We help customers to extend component lifecycles by combining condition-based assessments with continuous system improvements. By analyzing operating data from trains and systems, we identify wear and performance trends early on. This allows for timely, targeted maintenance that reduces downtime and cuts lifecycle costs. At the same time, small design enhancements and continuous system improvements help to optimize maintenance processes – ensuring long-term reliability and availability.

Obsolescence engineering

Managing the risks associated with discontinued components is ensured through tailored solutions. Typically, these include identifying suitable alternatives, re-engineering critical parts, and developing our own custom replacements. Structured obsolescence strategies safeguard long-term maintainability and operational continuity, even when original OEM parts are no longer available. Depending on the specific case, our in-house 3D printing capabilities enable us to produce replacement components quickly and cost-efficiently, ensuring critical parts remain readily available when needed.