More mobility by rail: Boosting transportation capacity by optimizing adhesion performance.

As well as improving operational stability and punctuality, bringing trains reliably to a halt within defined stopping distances is also key to increasing service frequency and thus to boosting transportation capacity. To this end, the functional combination of an innovative deceleration control system and enhanced wheel slide protection with a wheel/rail adhesion management system that will in future be capable of adapting to different situations plays a key role in Knorr-Bremse’s Reproducible Braking Distance (RBD) concept. In order to obtain a comprehensive and accurate data base for the development of this functionality, DB Systemtechnik and Knorr-Bremse carried out a test program with the advanced TrainLab, funded by Shift2Rail. DB Systemtechnik also plans to use the results for advanced wheel slide protection and adhesion management system testing on its wheel slide protection test rig. In the future, it aims to use the test rig to replace operationally challenging in-vehicle testing and expand the testing conditions and criteria for extremely low wheel/rail adhesion conditions with a view to automatic train operation (ATO).

Contact

80809 München

Deutschland - Germany

carina.smid@knorr-bremse.com

Collaborative project measures adhesion conditions at wheel/rail contact

Rail transportation plays a key role in meeting today’s mobility and transportation requirements. However, its acceptance is particularly dependent on operational stability, i.e. factors such as punctuality and reliability. These factors are strongly influenced by braking distance reliability – in other words, how reliably trains come to a halt within an operationally defined range so that they do not overshoot signals or stations, for example. Taking both current and future signaling technology (e.g. LZB/ETCS) into account, the same applies to the prospect of improved rail infrastructure capacity utilization thanks to reduced headways, especially in the context of Automatic Train Operation (ATO). Here too, braking distance reliability plays a significant role, especially in reduced wheel/rail adhesion conditions, for example if the track is wet or there are leaves on the line [1].

As part of its Reproducible Braking Distance (RBD) concept, Knorr-Bremse is currently creating the first functional combination of an innovative deceleration control system, an enhanced wheel slide protection system, and a train-wide wheel/rail adhesion management system that will in future be capable of adapting to different situations. The end product is a seamlessly coordinated and optimized overall system. Adhesion management will initially be implemented through a sanding unit configuration specially designed to significantly improve wheel/rail contact adhesion values that have been negatively affected by track contamination and environmental conditions.

In October 2019, Knorr-Bremse and DB Systemtechnik carried out a test program as part of the PINTA2 project (EU Horizon 2020, GA number 826054) of the EU’s Shift2Rail program. The aim was to obtain an extensive data base in order gain a better understanding of the physical conditions that occur at the wheel/rail contact and to shed light on the relevant interrelationships by plotting concrete adhesion curves. As part of the EU program, the data are entered into an “adhesion catalog” that documents real-life wheel/rail adhesion conditions. The catalog is a key tool for developing and validating additional adhesion-related functions.

The program sought to address the relative paucity of operational data on very low wheel/rail adhesion values, especially due to black leaf layer, although basic measurements have already been carried out in research projects at the University of Twente and Delft University of Technology, for example [2]; [3]. More recently, a large-scale study testing the performance of sanding units (using two sanded axles) in low wheel/rail adhesion conditions on a four-car train was carried out by the RSSB (Rail Safety and Standards Board, UK) [4]. In this study, the track was prepared with paper tape in order to simulate the leaf layer. Paper tape was also used within the fall rail service operational optimization program in 2003 by DB Regio and DB Systemtechnik. Within this project, sanding unit and wheel slide protection algorithm optimizations where developed and tested [5].

Summary

As well as improving operational stability and punctuality, bringing trains reliably to a halt within defined stopping distances is also key to increasing service frequency and thus to boosting transportation capacity. To this end, the functional combination of an innovative deceleration control system and enhanced wheel slide protection with a wheel/rail adhesion management system that will in future be capable of adapting to different situations plays a key role in Knorr-Bremse’s Reproducible Braking Distance (RBD) concept. In order to obtain a comprehensive and accurate data base for the development of this functionality, DB Systemtechnik and Knorr-Bremse carried out a test program with the advanced TrainLab, funded by Shift2Rail. DB Systemtechnik also plans to use the results for advanced wheel slide protection and adhesion management system testing on its wheel slide protection test rig. In the future, it aims to use the test rig to replace operationally challenging in-vehicle testing and expand the testing conditions and criteria for extremely low wheel/rail adhesion conditions with a view to automatic train operation (ATO).

Extra sanding unit and measuring equipment installed on advanced TrainLab test train

The tests were carried out with Deutsche Bahn’s advanced TrainLab (aTL), a modified class 605 four-car diesel-electric multiple unit (2'Bo'+Bo'2'+2'Bo'+Bo'2') with a traction power of 1,700 kW (Figure 1).

An additional sanding unit (in front of the 3rd wheelset in the direction of travel), track watering equipment, and measuring equipment and sensors were installed on the vehicle during a week-long setup phase at the fleet depot in Halle/Saale.

The existing onboard sensors such as the pulse generators used to measure the vehicle’s speed were connected to the decentralized measuring system. Further sensors were installed to generate additional signals for parameters such as brake pressure, brake disc temperature and environmental conditions (temperature, humidity), and to determine the reference speed. All signals were read at a high-resolution update rate of 200 Hz. The test vehicle’s lead car was fitted with the relevant control and monitoring systems to enable real-time monitoring during testing and to control the required actuation functions such as parametrization and activation of the sanding system. In order to ensure that the tests were carried out safely, the monitoring systems also included measures to prevent wheel stoppage.

The fact that sensors and measuring equipment were installed throughout the train made it possible to detect track conditioning (changes in wheel/rail adhesion conditions caused by the vehicle/multiple wheelsets crossing the same section) across all wheelsets. The test data can be used to quantify effects such as cross-improvement.

As far as the vehicle itself is concerned, the initial speed at which braking was initiated and certain parameters of the additional sanding unit installed in front of the third wheelset in the direction of travel were varied during the test runs. By employing this experimental sanding unit configuration, which differs from that found on production vehicles, it was possible to use the first two wheelsets to obtain a reference measurement of the current initial wheel/rail adhesion value during each test. The installed sanding system and an additional controller for dynamic supply pressure adjustment were used to vary the sand output and the timing of sand delivery. Additional cameras mounted on the car body provided a view of how the test was progressing under the vehicle.

Black leaf layer for realistic environmental conditions

In terms of infrastructure, extremely low adhesion values (µ < 0.03) at the wheel/rail contact were simulated on the 500-meter test section near Plau am See (Mecklenburg-Western Pomerania) by manually preparing the line with both leaves and paper tape. The aim of depositing leaves on the line was to create a black leaf layer, recreating environmental conditions that, while rare, do sometimes occur in an operational setting (Figure 3).

In conjunction with the watering equipment installed on the vehicle, this made it possible to achieve the requisite low wheel/rail adhesion values.

At the beginning of each measurement, the train was accelerated to initial speeds of 40, 70 and 100 km/h. When the vehicle entered the test section, (pneumatic only) emergency braking was initiated, and time- or speed-dependent quantities of sand of 400g/30s +100g (v < 140km/h) up to a maximum of 7.5g/m were delivered onto the wheel/rail contact. It was also possible to choose between two sand pipe diameters and to vary the sand pipe delivery position, allowing additional aspects to be investigated. The measuring system was equipped with a time stamp, enabling pooled and synchronized storage of all recorded measurements for analysis at a later point in time.

Tests were carried out alternately in both directions of travel, with and without deployment of the sanding unit. This made it possible to measure both the reference conditions at the wheel/rail contact and the modified conditions after sanding. The use of two unsanded wheelsets (the first and second wheelsets in the direction of travel) to provide reference measurements of unsanded conditions even when performing measurements with active sanding proved extremely useful both when carrying out the tests and for the subsequent analysis. A total of more than 250 individual measurements were made during the testing program.

Analysis and application of recorded measurements

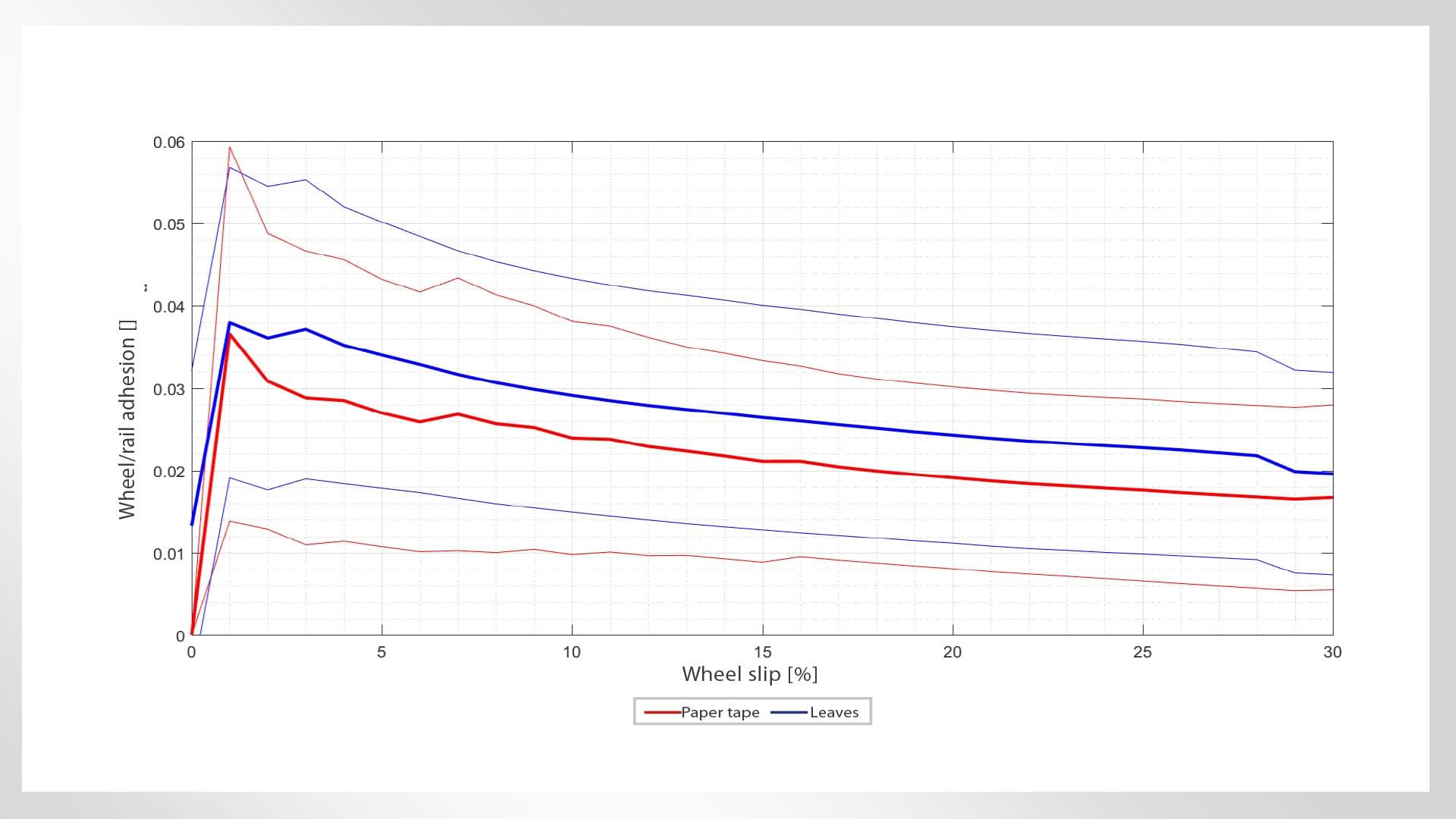

The recorded measurements demonstrated that the wheel/rail adhesion values that can be achieved with wet paper tape are similar to the natural adhesion values that occur with wet leaves. The curves were very similar in both cases, showing the characteristic peak at very low slip values and a progressive drop in adhesion as slip values increase. While there was some variation in the individual values depending on the number of times that the same track preparation was crossed, they were all of a similar magnitude (Figure 4).

The braking tests also sought to investigate the relationships between wheel/rail adhesion values and sand output. It was found that a sand output of 400g/30s (as stipulated by ERA/ERTMS/033281; [6]) has almost no effect on the braking performance of the entire train, especially when braking from an initial speed of 100km/h. However, it is precisely in this relatively high speed range that most of the braking distance increase would occur when braking in real operating conditions (“loss” of braking performance).

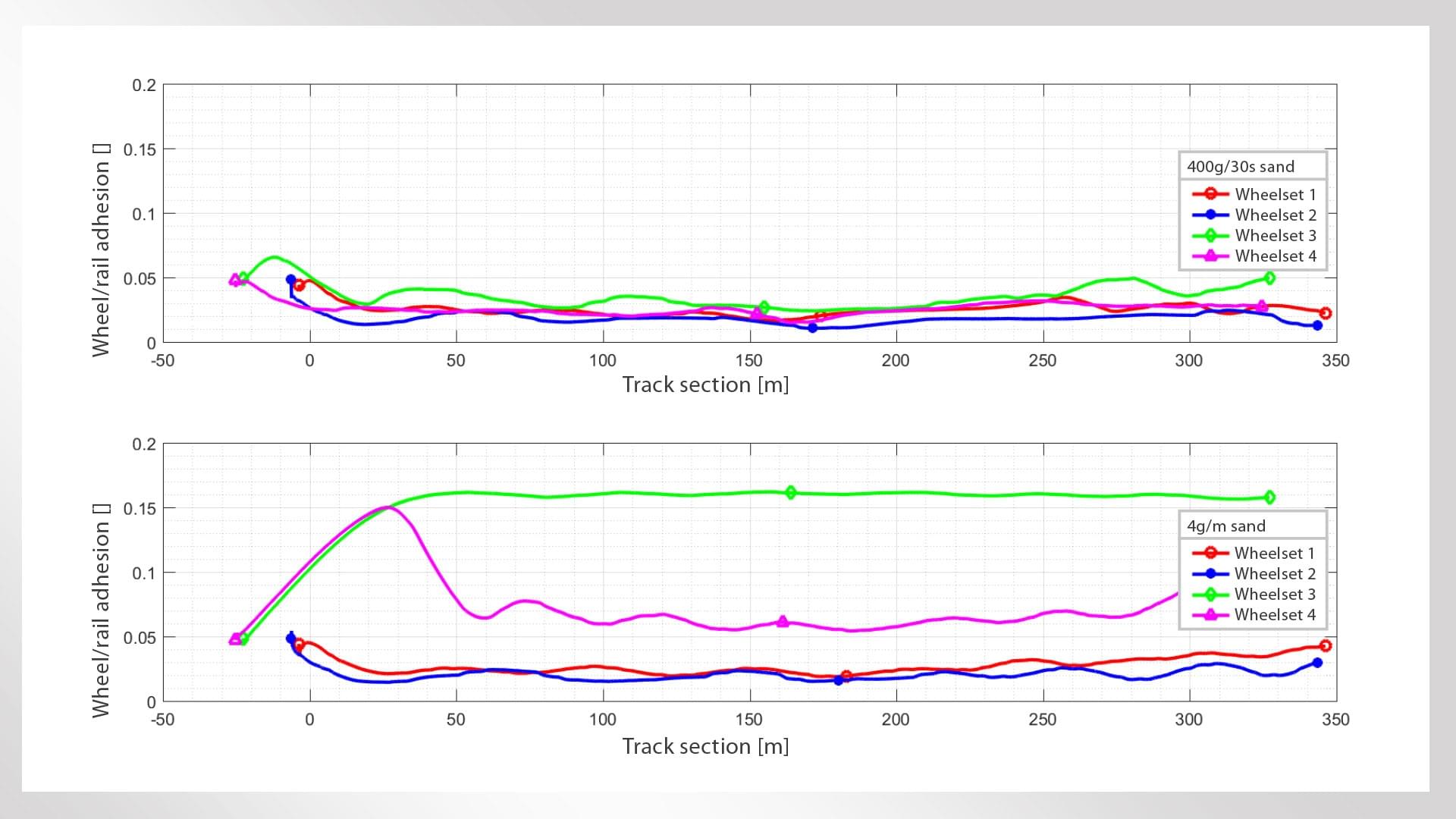

At these constant sand output values, the sanding effect gets progressively stronger at lower speeds. Effective increases in sand output (e.g. 2g/m, 4g/m, 7.5g/m) generate a much more pronounced effect, even creating essentially dry wheel/rail adhesion conditions for individual wheelsets (Figure 5, third wheelset).

The preliminary analysis suggested that changing the sand output from a time-dependent 400g/30s to a distance-dependent 2g/m, 4g/m or 7.5g/m increased the wheel/rail adhesion available for braking by 150%, 210% and 310% respectively compared to time-dependent sand output.

However, due to the different numbers of tests from the different initial speeds, the statistical robustness of the results is variable. These preliminary estimates are now being refined, and the effect of different sand pipe positions and changes to other parameters is still being analyzed.

The adhesion-related data sets from the measurements (reference conditions and values after sanding) provide a body of data that can now be used in various ways by the participants in the test program.

At Knorr-Bremse, the test data are being used to inform the development of adhesion management concepts as part of the Reproducible Braking Distance (RBD) project. The data sets also provide information that can be used in the design of the sanding systems themselves, for instance with regard to the optimal sand output or different ways of installing the sanding units. The data can also be used to carry out a cost-benefit analysis with a view to optimizing the overall system in terms of operation (adhesion), infrastructure (wheel/rail wear, track superstructure contamination) and maintenance (sand consumption).

The measurement data also complete the picture for tests that have already been carried out on Knorr-Bremse’s ATLAS (Advanced Test Laboratory for Adhesion Based Systems) dynamometer. The values recorded during the in-vehicle testing can be used to validate previous test rig measurements (deceleration, braking distances, etc.). At the same time, the adhesion data from the in-vehicle tests can also be used to define the reference conditions when setting wheel/rail adhesion conditions on the test rig.

DB Systemtechnik is using the results of the data analysis to simulate extremely low wheel/rail adhesion conditions on its wheel slide protection test rig. They hope that by combining test rig and in-vehicle testing they will be able to test the control behavior of wheel slide protection systems over a wider adhesion range without the need for additional in-vehicle testing. It may even be possible to replace some operationally challenging wheel slide protection tests entirely with tests carried out on the test rig.

A knowledge of vehicle braking distance safety under low and extremely low wheel/rail adhesion conditions is particularly important in the context of ATO. It may be necessary to supplement the established UIC 541-05 and EN 15595 standards with additional criteria. To this end, the measurements recorded during the test program provide valuable input data for the wheel slide protection test rig.

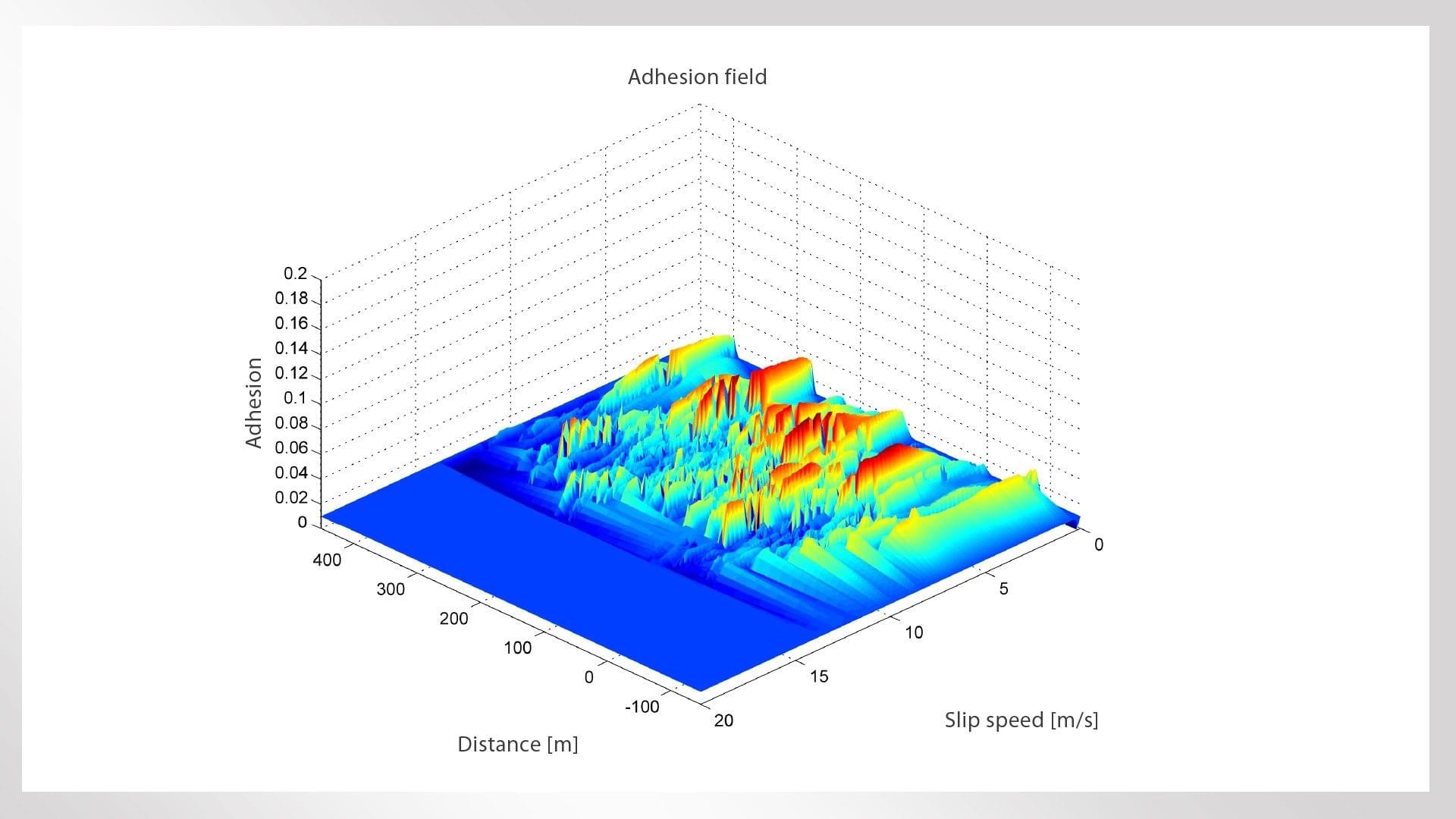

The wheel slide protection test rig uses distance- and slippage-dependent adhesion windows as a data base for simulating the wheel/rail contact. These must first be generated from the recorded measurement data. Since wheel/rail adhesion was not measured directly, it is calculated on the basis of the recorded values, taking into account the vehicle parameters as a function of slip speed and the distance covered. Thanks to the high number of individual measurements carried out during the test runs, it is possible to generate a wide range of adhesion profiles for the wheel slide protection test rig (Figure 6).

By modeling variations in the natural conditions that occur during the fall, these profiles provide the basis for test rig testing with extremely low wheel/rail adhesion values.

The reference braking maneuvers when the sanding unit is not activated are of particular interest for this use case. The fact that all the wheelsets in these braking maneuvers were directly affected by the adhesion conditions generated by the track preparation makes it possible to quantify the conditioning effect (i.e. how wheel/rail adhesion is affected when several wheelsets cross the same section).

Critical analysis

Regardless of whether measurements of physical effects such as the wheel/rail contact are carried out on test rigs or during in-vehicle testing, the multiple constraints and the many different parameters that need to be taken into account generally mean that it is not possible to fully answer all the questions that a particular test sets out to investigate. This is also true of the tests described above, which were carried out as part of the development of a wheel/rail adhesion management system that will in future be capable of adapting to different situations.

For example, the fact that the prepared test section was limited to a usable distance of 500 meters for the measurements described in this paper meant that it was not possible to bring the train to a complete halt from high speeds. Factors such as the amount of work involved in preparing the track and the target number of repetitions for individual tests meant that this could not be done in the time available. However, it is possible to partially compensate for these types of constraint by combining measurements from different initial speeds once the tests have been completed.

It was not possible to determine the electrodynamic braking forces at wheelset level during the tests. Consequently, only electropneumatic braking force generation was used to brake the vehicle. The vehicle architecture thus limited the maximum braking force that could be generated on individual wheelsets, meaning that on some wheelsets the available adhesion could not be determined at every timepoint, especially for high sand outputs. However, this did not compromise the analysis, since the tests generally focused on extremely low adhesion levels, and it was possible at all times to record reference values without sanding.

One manifestly positive aspect of the choice of test vehicle is that test series of this type can essentially only be carried out on track sections that have had extremely little use and are thus unlikely to be electrified. Moreover, the fact that braking was performed differently for different wheelsets made it possible to simultaneously analyze different adhesion-slip curves in a single test.

Authors: Dr. Marcus Fischer, Kurt Haselsteiner, Dr. Ferenc Szekely, Sebastian Heinz, Felix Kröger

References

[1]: RAIB Rail Accident Report, Autumn Adhesion Investigation Part 3: Review of adhesion-related incidents Autumn 2005. Report 25 (Part 3)/2006, January 2007

[2]: Popovici, Radu Ionut. Friction in Wheel - Rail Contacts, PhD Thesis, University of Twente, 2010.

[3]: Arias-Cuevas, Oscar, Low Adhesion in the Wheel-Rail Contact. PhD Thesis, Technical University Delft, 2010.

[4]: RSSB Trial of Sander Configurations and Sand Laying Rates, T1107 Report. Issue 1, 2018.

[5]: Dr. Spiess, Peter. “Schmierfilm auf den Schienen – Systemlösungen für das Herbstproblem”, ZEVRail Tagungsband Schienenfahrzeugtagung Graz 2005

[6]: Interfaces between the Control-Command and Signalling Track-side and other Subsystems. ERA/ERTMS/033281, Version 4.0. 20.09.2018