© Siemens Mobility

To ensure train subsystems never fail, they’re usually serviced at manufacturer-specified intervals that include generous safety margins. While this makes the actual maintenance much easier to plan and process, it’s not the most efficient way to manage a fleet. To balance both sides of the equation, Knorr-Bremse and Siemens Mobility have joined forces in a world first.

No doubt about it – faulty air-conditioning systems that stop working in summer, just when they’re most needed, are a major headache for train passengers everywhere. So when manufacturers calculate the maintenance intervals for their systems, they tend to add safety margins large enough to ensure that even the most hardworking system doesn’t break down unexpectedly. The major disadvantage of this approach is that systems and components are often overhauled or even replaced “too early”, cutting short their still valuable service life.

Knorr-Bremse and Siemens Mobility are now making a major break with this long-standing tradition by launching the world’s first joint venture between a leading systems supplier and a leading vehicle manufacturer to digitally monitor the status of onboard HVAC systems. The technical term is “remote condition monitoring”!

Smart data analytics optimize operation and reduce energy consumption

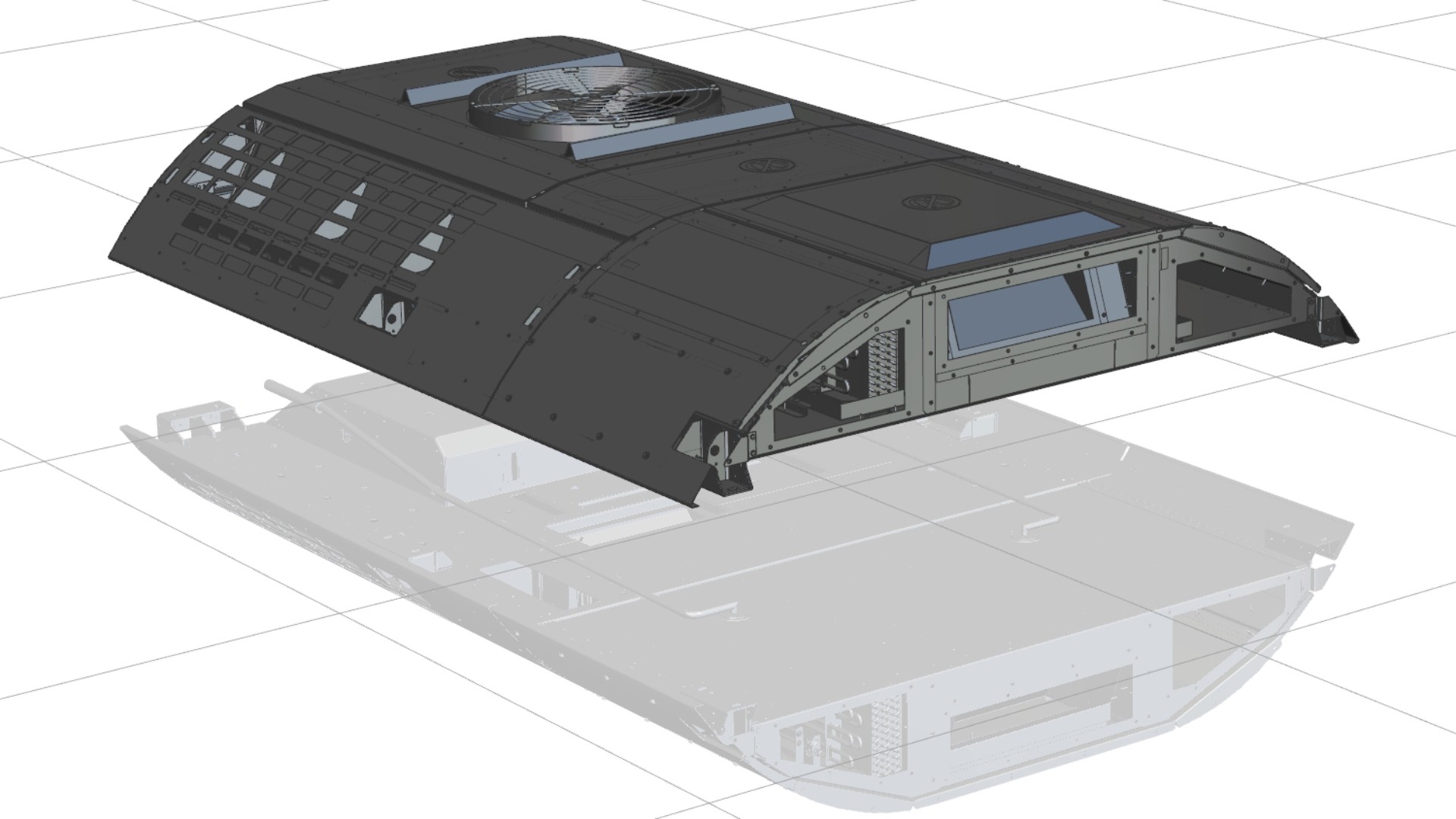

In their first project together, the partners will retrofit 733 HVAC systems on 172 regional trains run by UK operator South Western Railway with a kit featuring Knorr-Bremse’s digital solution for remote condition monitoring . The kits comprise hardware and software, an additional sensor unit that collects and records operating data from the HVAC systems, plus a cloud solution to intelligently analyze the data. From the resulting “big data insights”, Siemens Mobility’s service teams will quickly be able to identify a system that may soon need repairs through their Railigent® platform. This will allow them to respond proactively – long before an unscheduled repair jeopardizes vehicle operation. At the same time, this flexible approach makes much better use of each system’s remaining service life.

“We regard ourselves as a digital systems house,” explains Dr. Nicolas Lange, who chairs the Management Board of Knorr-Bremse Systeme für Schienenfahrzeuge GmbH. “That’s why we’ve been steadily expanding our digital services and enhancing our remote condition monitoring solutions in particular. So now we’re able to give South Western Railway’s fleet a major upgrade and bring it into the digital age.”

The partners started to install the new HVAC system kits in Q3 2021, aiming to finish by the end of Q1 2022. This means that the new solution should be ready to go into operation by the spring of 2022.

Demand-based air supply improves in-vehicle air quality

But there’s another benefit associated with retrofitting the new kits: a set of sensors in the HVAC systems that monitor the onboard air’s CO2 content. If the air quality falls below a certain level, more fresh air is fed into the vehicle. But improved air quality isn’t the only extra benefit of the setup. Because fresh air often needs to be heated or cooled, this demand-based air intake also reduces the train’s environmental footprint.