CubeControl – new generation for high-speed trains

For years, Alstom has relied on Knorr-Bremse’s modular CubeControl brake control system in a wide variety of rail projects around the world. Now the French manufacturer is installing the latest generation of the platform on a high-speed train fleet soon to be running in Sweden.

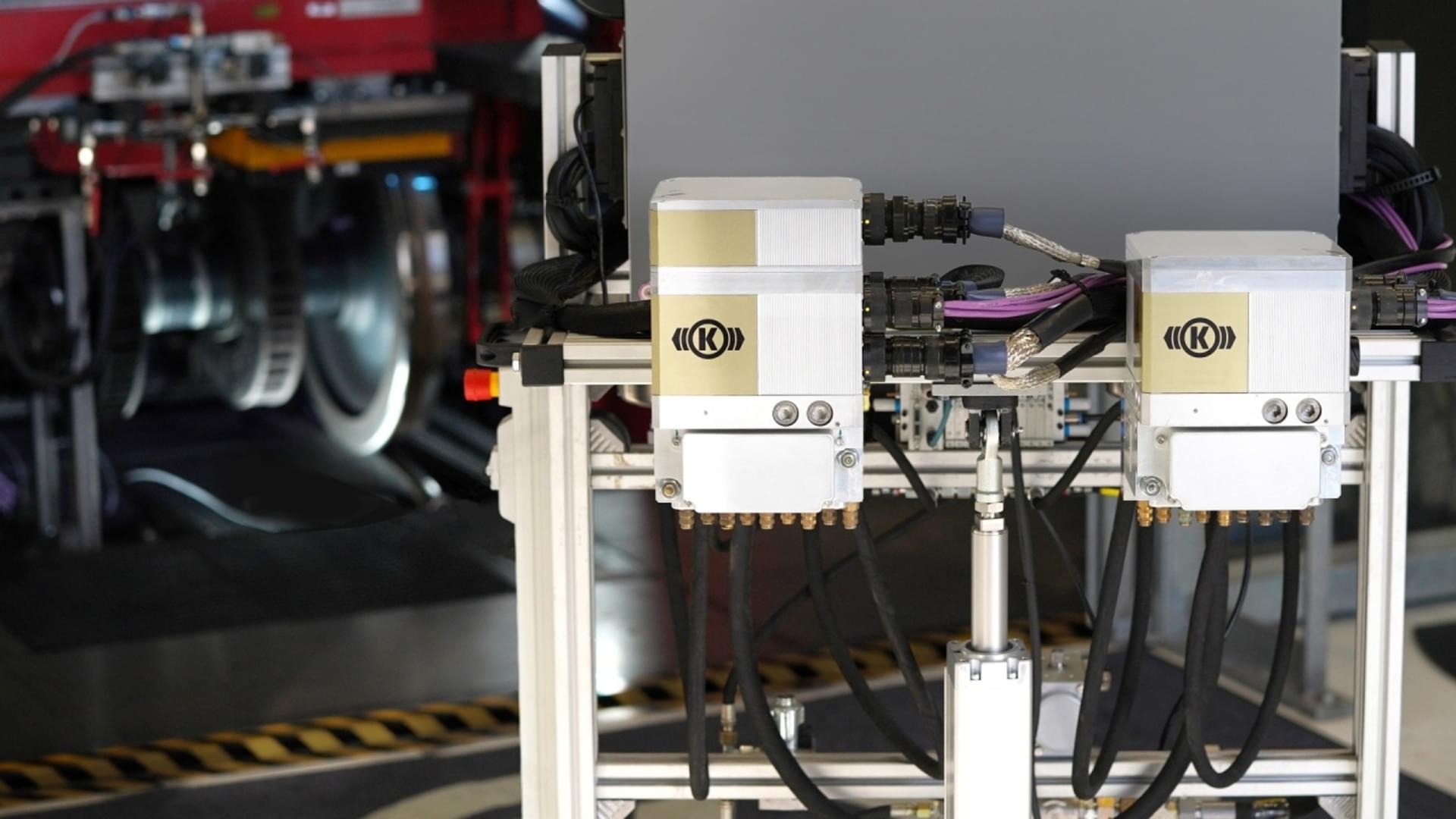

A brief recap: CubeControl had not long been on the market when Alstom had to make an important decision. Shanghai Metro had just ordered 12 Metropolis eight-unit LRVs from the French manufacturer for the West-Extension (as it was then) known of Shanghai’s Line 2, and the metro trains required a state-of-the-art control system capable of optimizing brake performance in any situation, based on multiple variables such as – to pick one example – passenger weight distribution. Alstom decided in favor of CubeControl, at that time still marketed under the product name EP 2002. Knorr-Bremse was ready to deliver immediately, so Alstom was able to install the first “Cubes” – each one a single mechatronic unit integrating all mechanical and electronic components – in the Metropolis rail vehicles back in 2007.

The manufacturer’s UK arm (then still known as Bombardier) had already installed CubeControl in vehicles destined for London’s sub-surface lines and underground Victoria Line (2005), and aboard the Aventra platform for the Crossrail project. To date, more than 130,000 CubeControl units have been delivered to over 350 projects worldwide. One of the main reasons for CubeControl’s popularity? Knorr-Bremse’s regular, ongoing upgrades of the brake control system.

Latest CubeControl upgrade delivers even better braking performance and dynamics

New Ethernet specifications have opened up connectivity to other systems and enabled condition-based maintenance (CBM). The system now includes functions such as Brake Disc Temperature Monitoring, which simulates the temperatures of the individual brake discs in real time and helps to avoid unnecessary speed restrictions. Optional integrations such as WheelGrip Adapt – the latest wheel slide protection (WSP) algorithm – can further reduce braking distances, even in extremely low-adhesion conditions. And increasingly, Deceleration Control (DCC) is decoupling deceleration from the highly variable conditions and tolerances typical of vehicles in operation. In future, the benefits of CubeControl will extend to other vehicle platforms such as regional and urban express trains, as well as high-speed intercity trains.

As the first manufacturer to order the latest generation of the system, Alstom is once again leading the way in the adoption of CubeControl – which Knorr-Bremse will now install on an Alstom-built fleet of Swedish high-speed trains over the next few years.

The new CubeControl upgrade integrates the various braking system components even more intelligently. Among other things, it enables more sophisticated synergy between electropneumatics, mechatronics, smart software and data. This further enhances braking performance and dynamics, making it possible to proactively avoid delays. And by combining several of the innovations described above, CubeControl’s latest upgrade will also enable Reproducible Braking Distance (RBD), a trailblazing feature slated to appear when the upgrade is launched early next year. Deliveries to Alstom will start in 2024 and are scheduled to continue into 2028.