Competitive rail freight needs railcars that support digitization and automation

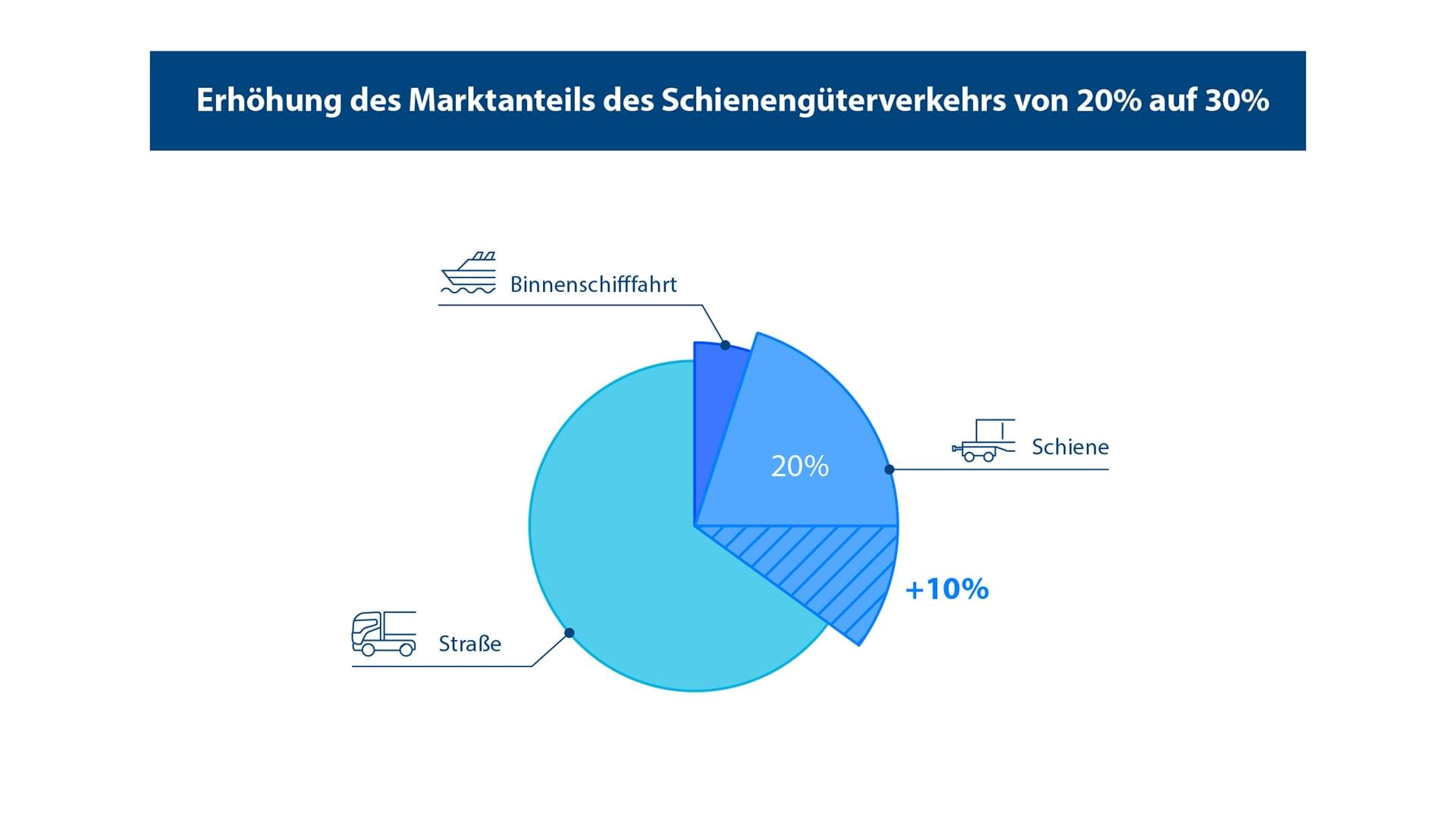

In the quest to reduce carbon emissions, it makes sense to focus on the transportation sector, which represents the largest energy consumer and third-largest greenhouse-gas producer in Germany [4]. Within the transportation sector, it makes equal sense to focus on rail. In tonne-kilometers, a truck emits about six and a half times more greenhouse gases than a freight train – approximately 111 grams, as opposed to just 17 grams [5]. These figures support the contention that the higher the rail sector’s market share, the more it will help to protect the climate. This is the premise for the EU’s ambitious target: to increase the proportion of freight transported by rail to at least 30 percent by 2030. In 2019, rail freight’s market share was still down at around 18 percent (Fig.1).However, as it stands, today’s rail freight sector is quite simply unable to support such an increase. Given the amount of time required to assemble freight trains, single-car routing in particular no longer meets twenty-first century requirements for flexible supply chains. The many manual processes involved in preparing, assembling and operating freight trains are a major reason why rail freight can no longer compete with transportation by road. The solution is to digitize and automate processes for trains and rail vehicles – but this requires railcars and locomotives that support end-to-end digitization and automation (Fig. 2).

Contact

80809 München

Deutschland - Germany

carina.smid@knorr-bremse.com

Abstract

To meet the goal set by the European Union (EU) – to increase the proportion of freight transported by rail to at least 30 % by 2030 (2019: approx. 18 %) [1] – the digitization and automation of the freight train (Digital Freight Train, DFT) is generally regarded as essential. The EU-sponsored Europe’s Rail Joint Undertaking (ERJU) [2] technology support program has given a correspondingly high priority to developing technologies for enabling the “shift” from road to rail, and to defining interoperability standards for rail freight vehicles. As the cornerstone of the DFT, the Digital Automatic Coupler (DAC) is especially important. In the near future, the DAC will automatically perform key processes that currently rely on time-consuming manual labor. It will also connect together power supplies and data communications along the entire length of the train. Several ERJU [3] work programs are now working hard to develop various demonstrators, including a reference test system.

ERJU makes freight car digitization and automation a top priority

Under the Europe’s Rail Joint Undertaking (ERJU) technology support program, the European Union and Europe’s rail industry have started to prepare the requisite technologies for market launch. The major players at rail operator and systems supplier level, including Knorr-Bremse, as well as research institutions and companies specializing in transportation infrastructure , are pooling their specific areas of knowledge and expertise to make this possible.One of the ERJU program’s Flagship Areas is dedicated to “Transforming Europe’s Rail Freight”, reflecting the importance Brussels has assigned to the comprehensive modernization of the rail freight sector. Within this Flagship Area, the program sponsor has clearly prioritized the digitization and automation of both freight cars and locomotives.Two work packages in particular will play a significant role in the near future. First, the “Digital Interoperable Freight Train” work package, which aims to build a manufacturer-independent market for automation solutions that will make freight trains both digital and interoperable. As part of this package, the vehicle control system manufacturers involved have undertaken to adapt their solutions to make them interoperable. The second work package, “Digital Automated Coupler Type 5”, is focused on making the various manufacturers’ coupling systems interoperable, and ultimately on automating them.

The Digital Automatic Coupler as enabler of the Digital Interoperable Freight Train

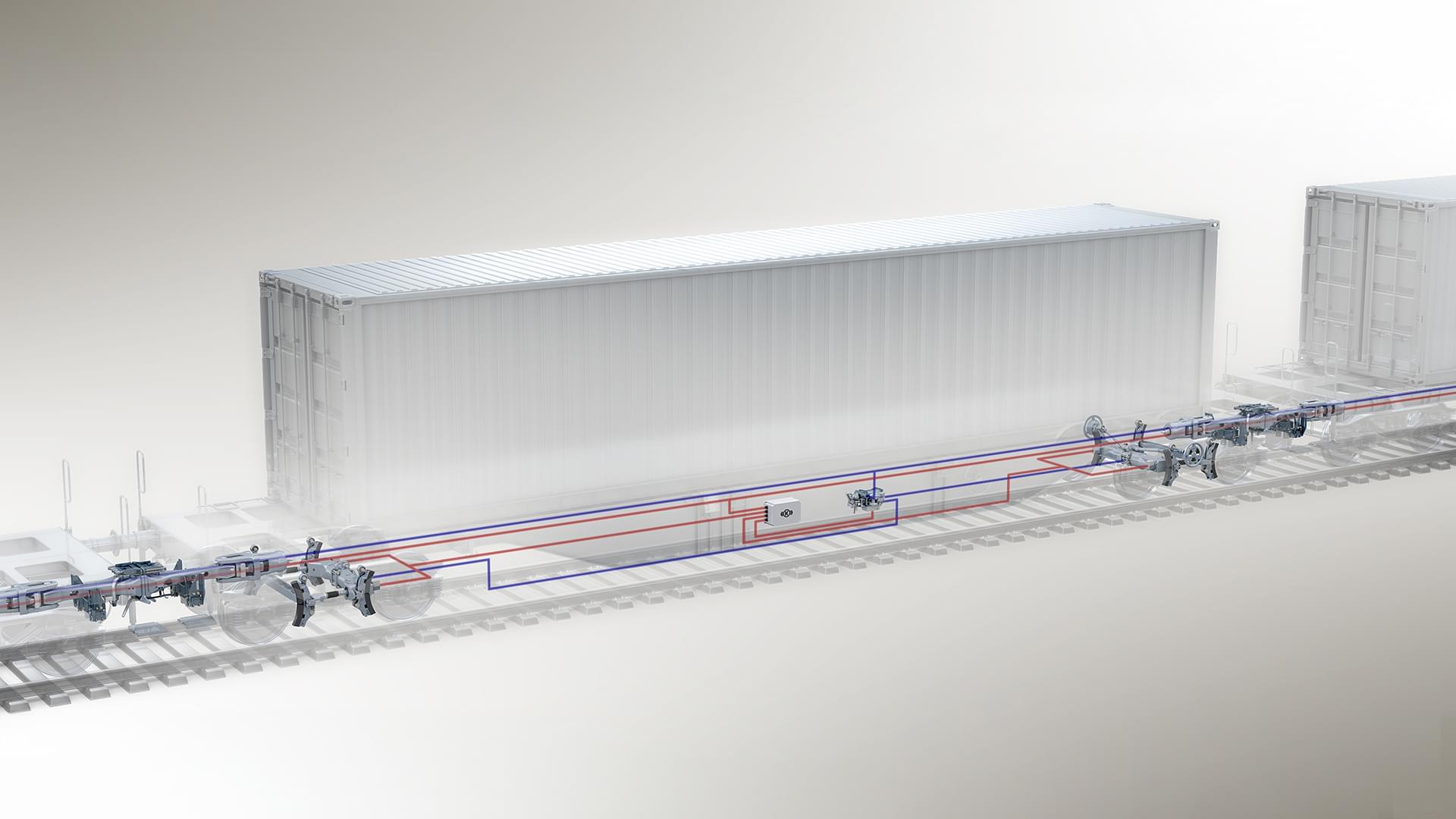

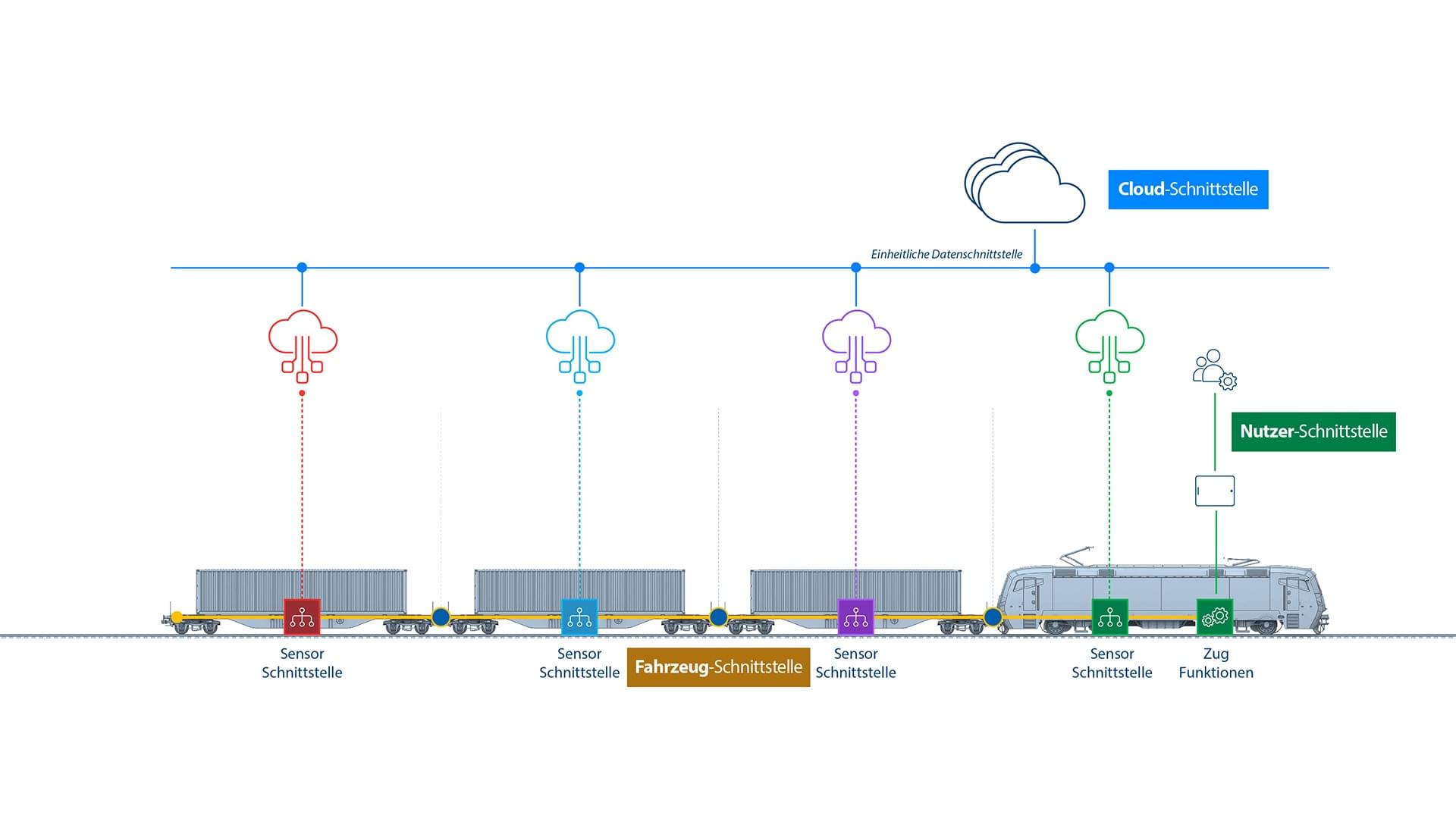

In all these projects, the Digital Automatic Coupler (DAC) acts as the key enabler. First, because it simplifies the enormously time-consuming manual coupling process by automatically establishing the mechanical and pneumatic connections between railcars and with the locomotive. And second, because it automatically connects the locomotive’s electrical power supply to the railcars and establishes a communications network along the entire length of the trainset. It is clear that the DAC can only deliver all its benefits if its various functions can be controlled directly from the driver’s cab.In addition to the DAC’s coupling and decoupling functions, three other functions are vital to efficient train operation. First, automated brake testing as a substitute for the labor-intensive, on-foot inspection of the entire trainset by shunting yard personnel. Designed as an end-to-end monitoring system, the brake testing system captures all relevant brake conditions and displays them on fixed or mobile digital devices in the driver’s cab in real time, via user-friendly interfaces. Second, automated train composition recognition and train integrity monitoring eliminate the need for end-of-train devices, speed up the train assembly process, and provide a basis for executing all the train’s safety-related functions. They also provide accurate information on the exact length of the train.Third, an automated parking brake will prevent railcars and groups of railcars from accidentally rolling away over an extended period of time by locking their wheels. And if the railcars are equipped with the appropriate control system and actuators (an additional requirement), it should also be possible to engage or release the parking brake from the driver’s cab.There are, of course, additional requirements to satisfy, such as energy management and secure communications within the trainset and to and from the cloud. In both cases, suitable measures for defending against cyberattacks must be put in place from the outset. Fig. 3 illustrates the DFT, complete with its digital and automatic functions and components. From left to right, these include the DAC, the Compact Freight Car Brake (TreadAct Freight), the Freight Control system, and the KEf distributor valve with sensor box.

ERJU work package to “establish functional interoperability”

The real-world value of digitized, automated rail freight transportation stands and falls on the basis of the European standards governing the interfaces between mechanical components, power supplies, data communications and thus the actual train functions. The keyword here is “interoperable vehicles”. The operational safety and security of these train functions must be defined as generically as possible for the whole of Europe’s rail freight sector (so should cover, for example, the specifics of the various regions, smaller and larger rail operators, etc.). This in turn will enable pan-European approvals and certification. This is why a standardized definition of operational processes for DAC-equipped vehicles is required.This definition of interoperability is currently being formulated in close consultation with the rail operators responsible for defining the standardized operational processes. According to the remit, the interoperability specifications for the DAC, the train’s locomotive-based power supply, the communication technology required for data transfers, and train functions in general, must be finalized by the end of 2023.Standardized operational processes are on the next level down from standardized train functions. In addition to the functional specifications, it is important to define interfaces for sharing data between vehicles, as well as between locomotives and users. In addition, a full test specification for validating functions in the course of laboratory and field testing is also required, as is the specification of a reference test system (Fig. 4).

Validation of manufacturer’s implementation of interoperability specifications

Implementation of ERJU specifications should be validated on the basis of field trials using real freight vehicles in the form of a train test lab, entailing the assembly of up to 100 freight cars and 4 locomotives in a single trainset. This work package includes the five following projects:

• Set up train lab and vehicles: Develop a demonstrator train to validate Digital Freight Train hardware and functions in a real-world operating environment.

• Reference test system: Develop a reference test system for end-to-end functional testing of all digitization and automation equipment intended for future freight trains to verify their compliance with the defined standards and interfaces.

• DAC functional train laboratory tests: Assure the interoperability of different types of DAC and investigate their suitability for migration, assembly and use in operation.

• Power supply and data communication train lab tests: Validate electrical power supply and data connections throughout the train and within individual vehicles.

• Train lab tests of train functions: Validate DFT train functions, including e.g. braking test, parking brake management, train composition recognition, train integrity monitoring, and usability of display and control elements.

Once the individual specifications have been successfully validated in the train test lab, as well as in other field-trial trains slated for operation starting in early 2025, the next step is to incorporate them into European standards. Like the EN standard for pneumatic braking systems, for example, that makes it possible to use distributor valves made by various manufacturers in a single trainset, similar sets of rules must be established for data connectivity, application profiles and power supplies.

Challenges prior to operational rollout

A vast project like this inevitably throws up a wide variety of challenges, of which the most significant – apart from the tight schedule for manufacturers – is probably the following: the hazard analysis to be performed, and the subsequent technical specification of coupling systems, power supplies, data communications and train functions. From the start, this process must result in sufficiently safe, reliable and interoperable technical solutions. Harmonizing the manufacturers’ various approaches to these solutions will also be challenging, and costs must be kept within specified limits.The certification of technical solutions will also play a key role on the way to operational rollout. This not only applies to the certification of the technical solutions themselves (under TSI and/or EN standards), but also and in particular to the broader requirement for an efficient, pan-European approval process. This is crucial for the effective migration of the solutions concerned, and will also apply to future new vehicles, as well as the subsequent validation of modifications to vehicle types already in operation.To achieve a standardized level of technology, the nature of the equipment to be fitted to vehicles during this migration must be defined as consistently as possible across the whole of Europe. Otherwise it would be pointless to invest in, for example, DAC5-equipped vehicles with the aim of coupling them to mixed trains that included DAC4-equipped vehicles. At this point, it is essential that policymakers in particular should take note of existing disparities in the availability of shunting personnel across Europe and engage in meaningful decision-making that transcends national boundaries. The migration of Europe’s rail freight fleet to a whole new level of technology must be planned and implemented in unwavering accordance with the harmonized target specifications. This requires the involvement of smaller rail operators, railcar suppliers, locomotive and rail vehicle manufacturers and their respective maintenance specialists across the whole of Europe.There will also be major changes in rail vehicle maintenance, because until now, electrotechnical/electronic maintenance in workshops has been confined to – for the most part autonomous – telematics systems. Here it will be important to pay particular attention to the technological paradigm shift during the introductory phase (Figs. 5 and 6).

Author: Steffen Jass

Litrature:

[1] Verband der Bahnindustrie in Deutschland (German Rail Industry Association, VDB): VDB-Klimabild 2030, Clean Mobility. Made in Germany. Discussion paper. (2019), p. 15.

[2] Funded by the European Union. The views and opinions expressed are, however, solely those of the author and do not necessarily reflect those of the European Union or ERJU. Neither the European Union nor ERJU may be held responsible for them.

[3] The project is supported by the Europe’s Rail Joint Undertaking (ERJU) and its members.

[4] Energy consumption by energy source and sector. Federal Environment Agency. https://www.umweltbundesamt.de , accessed March 30, 2023.

[5] Levels of greenhouse-gas emissions in German freight transportation sector in 2019 by mode of transportation. Statista. https://de.statista.com , accessed March 30, 2023.