Together, they’re driving forward the adoption of industrial 3D printing by the rail vehicle industry. As VP Production Rail, Bernhard Winkler in Munich is responsible for, among other things, Knorr-Bremse Digital Manufacturing, while Attila Kovács, Director Mechanical Design Engineering, masterminded the development of the first components produced by additive manufacturing at the company’s Budapest site.

Mr. Winkler, when we first talked about the potential of additive manufacturing in the rail industry, some four years ago, you brought a 3D-printed spare part to our meeting …

Winkler: … I did, didn’t I? We were very proud of it at the time – our first additively manufactured component to have actually been installed in a rail vehicle.

Tell us about it!

Winkler: Well, a major European operator was missing a very special spare part for an elderly, much-used vehicle that was actually still in good working order. The previous component had already been discontinued; there weren’t even any tools or jigs available for machining the blanks. So we used 3D printing to give the 40-year-old vehicle another few years of life on the rails. No question about it – a classic niche application. But our solution certainly got the job done!

Is it really as simple as that?

Kovács: Sadly, no! Just making it through to the prototype stage is very complex process, full of crucial questions: What’s the best design for delivering the required functionality? Which printing process is the best match for this specific application? And what about material composition? Finally, monitoring the actual printing process and its many parameters – such as temperature, printing speed, thickness of the layers and so on – is vital if you want to produce consistent, reliable components. And then, once you’ve finished printing, you need special test procedures to validate the mechanical properties, durability and performance of the printed product. Before we could finally install the spare part in that particular project, we put ourselves through an enormous, multidisciplinary learning process. So now we have a very good understanding of the technology, as well as the processes behind it.

But just manufacturing spare parts isn’t a great business case – or is it?

Winkler: Oh, I wouldn’t go so far as to generalize! If you want to produce small quantities of special components economically, your only realistic option is to use additive instead of conventional manufacturing techniques. While I’m sure additive manufacturing won’t replace existing processes, it can certainly bridge gaps in design scenarios that push traditional casting or milling processes to their limits.

Such as?

Winkler: For example, when you need to manufacture components with complex configurations that may have been optimized using bionics. Sometimes it’s apparently minor details that push conventional manufacturing to its limits – an air duct, for example, which needs be shaped in a particular way for a specific application and can’t be created by drilling. That’s the sort of situation where 3D printing comes to the rescue.

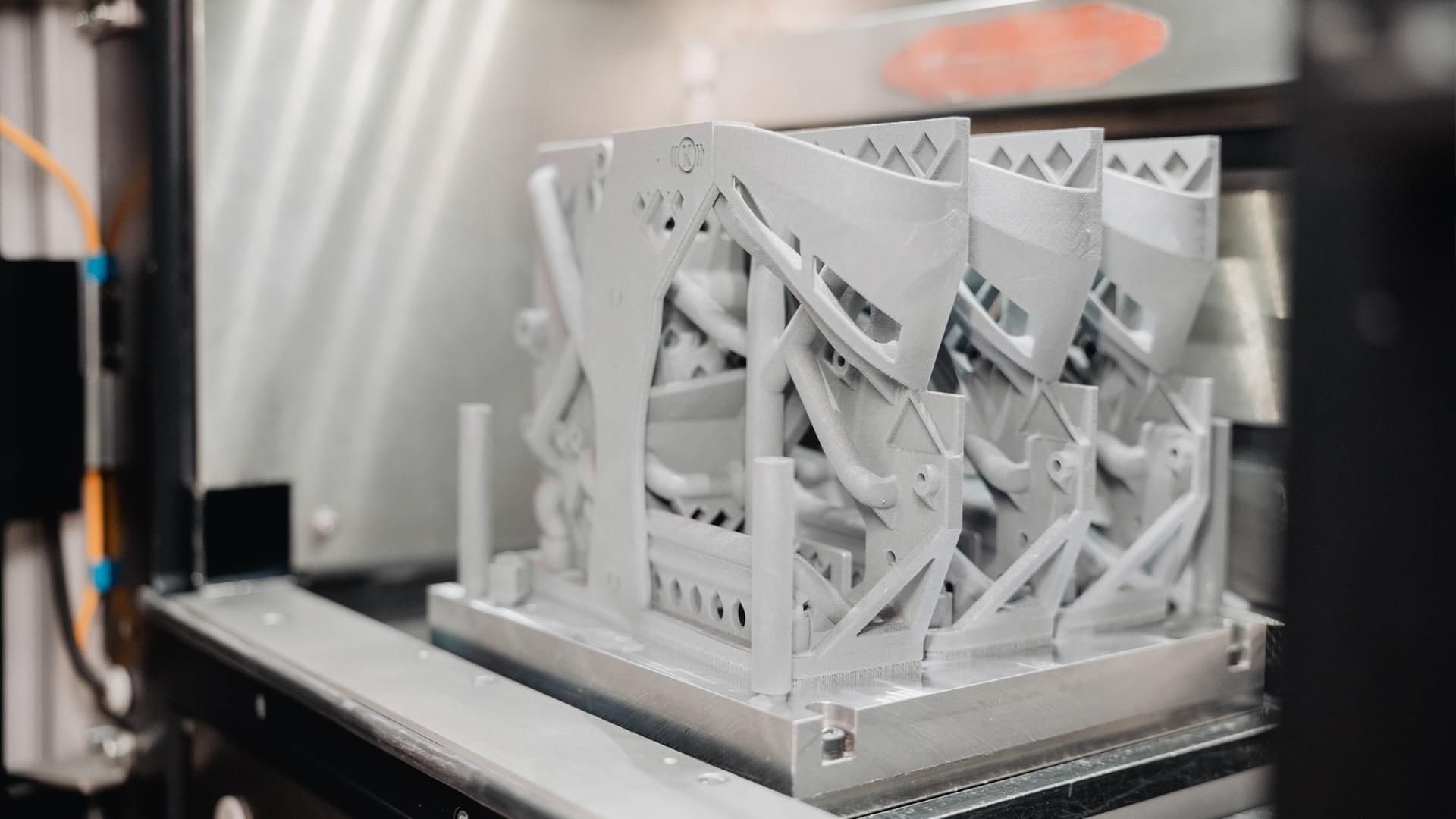

Kovács: Let’s be honest – we’re unlikely to be able to additively manufacture a complete brake disc in the foreseeable future, simply because brake discs have to cope with extreme stresses. Even so, by using this process, we’re turning classical manufacturing logic on its head. Instead of milling a workpiece out of a single block of metal, we use a laser to fuse together (“sinter”) a special metal powder, creating the required shape layer by layer. We call it our “design for function” approach, and it gives our development teams much greater freedom when they’re designing new rail vehicle components or optimizing existing components. Increasingly, the rail industry in particular wants complex, robust components that are also small and lightweight.

Kovács: Depending on the specific component, it’s not unrealistic to expect additive manufacturing to reduce its weight by anything up to 80 or 90 percent. Plus the other benefit: The component will be significantly smaller. We’re helping vehicle manufacturers to install increasingly advanced components in ever smaller spaces.

You’ve already supplied 3D-printed spare parts. So what’s the next step?

Kovács: Our colleagues in Budapest and Reims have just delivered the first pneumatic control module for a project in France. Again, it’s a retrofitting project, but it has enormous potential for our OEM business. One thing is certain: We’re now at the stage of moving on from purely

More function, less bulk: downsizing control panels

Industrial 3D printing is opening up interesting new possibilities for the rail vehicle industry. Knorr-Bremse will install its first additively manufactured auxiliary panels in vehicles for France’s SNCF.

Control modules have always been sturdy – mounted as they usually are on aluminum machined panels, they include various pneumatic and electropneumatic components, interconnected via numerous holes and air ducts. A manifold supplies each module with compressed air. “From a purely functional viewpoint, there’s quite a lot of superfluous weight and bulk in today’s rail vehicles,” explains Clément Coquerel, an industrial 3D printing specialist working at Knorr-Bremse France.

The same performance and strength as conventional panels – but 25 percent lighter and smaller

The control module that will be installed in an Autorail à Grande Capacité (AGC for short), a rail vehicle used by state-owned railroad operator SNCF, looks very different – it is substantially more compact, with an aspect more reminiscent of a lightweight cast part. Many of the ducts now run directly between the components rather than being drilled on several levels, as they were before.

“In terms of performance and strength, it’s a 1:1 match for the previous component,” asserts Coquerel. “But thanks to additive manufacturing, we’ve been able to slim it down so it’s purely functional and 25 percent lighter than conventional control panels.” The panels will be mounted with standard series equipment before being subjected to the full range of functional test sequences and approval tests on the train.

Info

In continuous operation for the sixth year running

In 2018, the “Approval in Rail” working group of the Mobility goes Additive e.V. network was formed with the aim of producing – for the first time – a safetycritical brake component for the rail sector using an additive manufacturing process, and then installing it in a rail vehicle. The component selected for this pilot project, a suspension bracket, connects the brake pad holder to the bogie frame. During the braking process, it absorbs the resulting tensile and compressive forces and transfers them from the brake pad holder to the bogie frame. Previously, Knorr-Bremse manufactured the component out of sheet steel using conventional oxyfuel cutting. For the additive manufacturing pilot, a new material was chosen: 1.4404 stainless steel. In summer 2019, the component was installed in a DT4 vehicle operated by Hamburger Hochbahn and is now in its sixth year of successful continuous operation.

Attractive scenarios include low-floor and high-speed applications

SNCF operates around 700 AGC vehicles across the French Republic in various configurations, including diesel, electric and dual-power versions. “The first of them went into service back in 2004. Now they’re being given a midlife overhaul, so it’s exactly the right time to install new components,” explains the engineer. Two control panels are installed on each train. In three trains, one of the two panels will be replaced by the new, 3D printed variant. The trial is scheduled to run for two years minimum – the first SNCF field trial to involve a component produced by additive manufacturing.

Although this is still a retrofit project, the situation is expected to change in the long term. “With this field trial, we aim to prove that these 3D-printed panels are just as easy to install in new vehicles,” says Coquerel, who is already looking forward to more ambitious projects.

The really important question here is whether 3D printing could also optimize other train components by reducing their weight and bulk. “We can easily imagine other attractive scenarios for this technology, such as the restricted installation envelope in low-floor vehicles or in future high-speed applications.”