Waste management is a critical component of a circular economy, where valuable raw materials can be reintroduced into the production cycle, minimising environmental burdens. At Knorr-Bremse Rail Systems UK, there is a strong emphasis on waste prevention and recycling. By integrating a metal briquetting machine at their manufacturing site in Corsham, Knorr-Bremse have demonstrated their commitment to sustainability and resource efficiency.

Briquetting Machine and Its Advantages

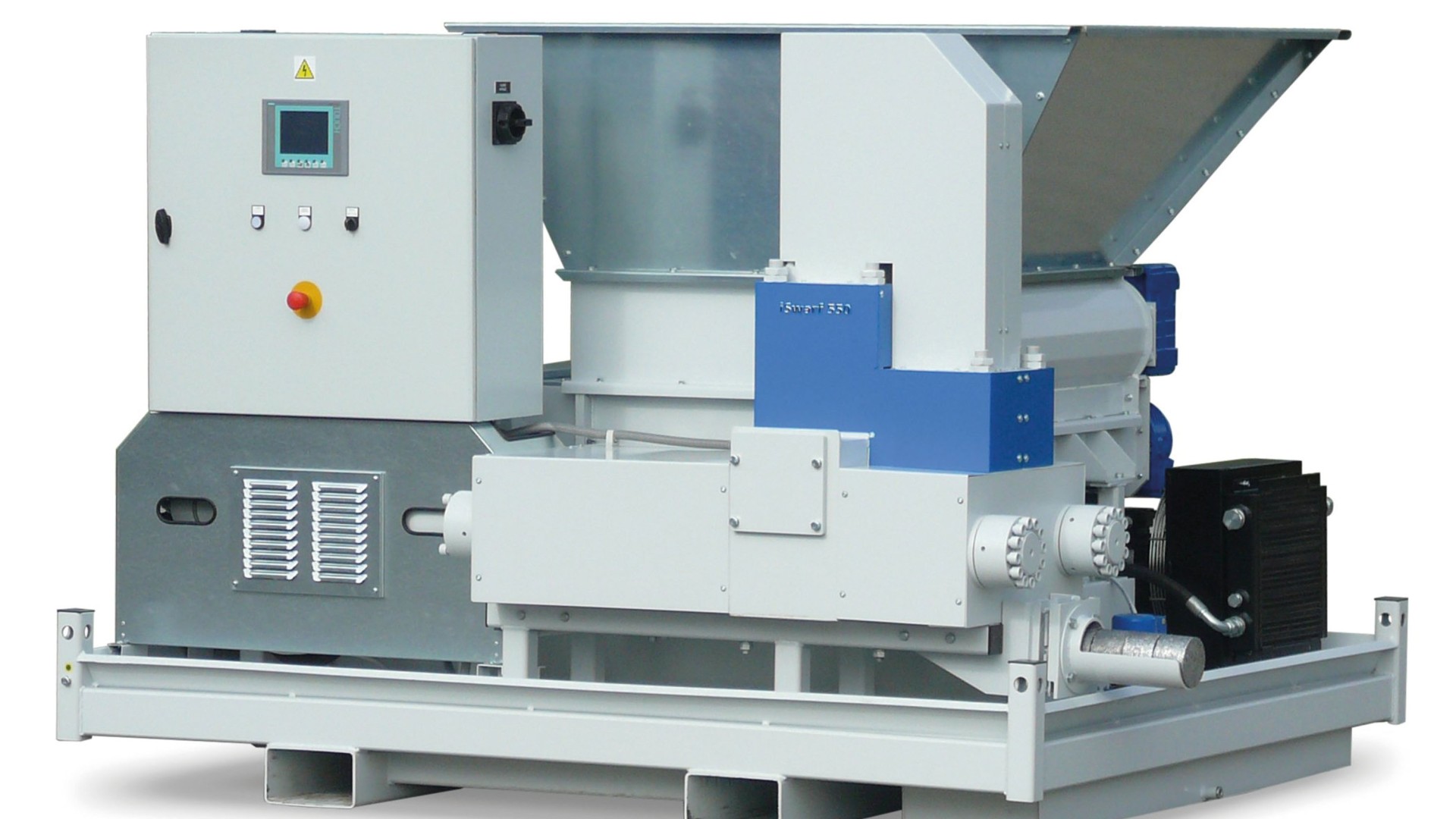

The newly installed metal briquetting machine compresses metal waste such Aluminium swarf and chips into dense, high-quality briquettes. This process, uses high pressure cylinders compacts a waste product into manageable and valuable bricks; it also removes residual cutting fluids which offer the opportunity for re-use.

The benefits of briquetting extend beyond waste reduction, offering several practical and economic advantages:

- Independence: Briquettes can be weighed on site and offered out to the market. This ensures the best price is achieved for any collection whilst giving transparency to all parties. Revenue Generation: The sale of briquettes opens new revenue streams. Currently, briquettes have a 44% higher value than traditional swarf.

- Waste Reduction: By significantly reducing the volume of waste, the need for disposal is minimized.

- Cost Efficiency: The briquetting process reclaims valuable cutting fluids , reducing coolant loss by an estimated 18%.

- Environmental Impact: Compacted briquettes facilitate easier and more efficient transport, cutting down on emissions and reducing the carbon footprint.

Operational Impact and Savings

Since the installation of the briquetting machine in January 2024, Knorr-Bremse has observed substantial operational savings and environmental benefits:

- Reduced Transport: Waste collections have been reduced from six to one per month, saving 160 miles of travel monthly, reducing emissions and wear on infrastructure.

- Economic Benefits: Over 71 days, the briquetting machine processed nearly 20 tonnes of material, yielding an additional £5.86k in revenue over swarf. Annually, this translates to an estimated additional income of £32k, with running expenses around £4.84k.

- Coolant Recovery: With the reintegration of reclaimed fluids, an additional £20.7k savings is anticipated.

Commitment to Sustainability

Knorr-Bremse’s waste management aligns with the principles of a sustainable circular economy. The company adheres to three core principles:

- Waste Avoidance: By optimising resource use, KB minimises waste generation.

- Substitution: Environmentally friendly materials replace less sustainable options, such as avoiding single-use plastics.

- Recycling and Reuse: Materials are recycled in environmentally responsible ways, promoting a circular economy.

The briquetting machine supports these principles by converting metal waste into reusable and sellable products, significantly cutting down on waste and enhancing sustainability efforts.

Knorr-Bremse’s Climate Strategy

In pursuit of sustainable mobility and climate protection, Knorr-Bremse has set ambitious goals aligned with the 2015 UN Paris Agreement. Their Climate Strategy 2030 focuses on:

- Energy Efficiency: Implementing measures to enhance energy efficiency and using low-carbon fuels.

- Renewable Energy: Investing in self-generated renewable energy and increasing the purchase of renewable energy.

- Scope 3 Emission Reductions: Aiming to reduce emissions from the value chain by 25% by 2030, focusing on key areas such as purchased goods, transportation, and the use of sold products.

Conclusion

The integration of the briquetting machine at Knorr-Bremse Rail Systems exemplifies the company’s commitment to sustainability and efficiency. By transforming metal waste into valuable briquettes, Knorr-Bremse not only reduces environmental impact, but also enhances operational efficiency and economic returns. This initiative is a significant step toward achieving their broader climate and sustainability goals, showcasing how innovative waste management can contribute to a sustainable future.

Your Knorr-Bremse Rail Systems UK-Team

Other local activities

We are proud to support "Rail Safe Friendly", a programme dedicated to promoting rail safety awareness directly to school children in the UK.

Read more

We are proud to present the remarkable achievement of installing the largest curved standing solar roof in the UK at our manufacturing site in Melksham.

Read more