Joleene Knight (fitter/tester) and Gary Davis (assembler) carry out maintenance on an HVAC system from a Chiltern Railways Class 168 diesel multiple unit at Knorr-Bremse Rail Systems’ HVAC facility in Calne, Wiltshire.

Knorr-Bremse Rail Systems has secured an extension of its HVAC repairs, spares and on-site support maintenance contract with Chiltern Railways for a further five years.

The contract cements the existing long term relationship between Chiltern Railways and Knorr-Bremse developed over the last decade. Initially focussed on supporting KBRS (UK) Class 168 HVAC systems, this agreement now encompasses all HVAC systems installed on the Chiltern fleet.

Paul Battams, Knorr-Bremse Rail Systems (UK) Ltd Business Development Manager, said: “This is great news for Knorr-Bremse. This contract solidifies our position as the unrivalled market leader for the supply of HVAC overhaul, repairs and spare parts and proves our commitment to long-standing customers. It also highlights our ability to work on HVAC systems produced by various manufacturers.”

HVAC is the heating, ventilation and air conditioning fitted to the trains. The work sees Knorr-Bremse responsible for 358 HVAC systems across Chiltern Railways’ Class 165 and Class 168 diesel multiple units as well as the operator’s ‘Silver Set’ Mk 3 coaches and driving van trailers. Under the contract, Knorr-Bremse will work with other maintenance providers such as Arriva TrainCare, which works with Chiltern Railways. Knorr-Bremse is conducting the overhaul work at their state of the art HVAC facility in Calne, Wiltshire, supported by a dedicated on-site repair team at Chiltern Railways’ Aylesbury depot.

Phil Andrews, Head of Engineering Commercial at Chiltern Railways, said: “We are delighted to have renewed our partnership with Knorr-Bremse. This is a well-established relationship put in place for the maintenance and repair of the heating, ventilation and air conditioning systems fitted to our trains which are crucial for our customers’ travel experience.”

If you would like to know more about HVAC overhaul, repairs, spares and modernisation within Knorr-Bremse Rail Systems (UK) for your HVAC systems, please visit: Knorr-Bremse Merak Website

For further information please contact

Melksham

SN12 6TL

United Kingdom

Paul.Battams@knorr-bremse.com

Local activities of Knorr-Bremse UK

Knorr-Bremse Rail Systems has collaborated on the new €3.5 billion (£2.92 billion) Metro scheme serving Thessaloniki which opened on 30th November 2024. The 9.6 kilometre-long line features 13 stations and has an expected ridership of 678,000 passengers per day, equalling 116.8 million passengers per year.

Read more

At just 12 years old, Elliott Drury is already making making a name for himself in the competitive world of karting. Supported by Knorr-Bremse, this young talent has shown remarkable progress and resilience in his first year of outdoor karting, setting the stage for an exciting future in motorsports.

Read more

We are proud to support "Rail Safe Friendly", a programme dedicated to promoting rail safety awareness directly to school children in the UK.

Read more

In the world of high-performance engineering, precision and dedication are paramount. These same qualities are exemplified by Regan Toop, not just in his role as an Engineering Technician Apprentice at Knorr-Bremse, but also in his remarkable journey as a competitive kayaker.

Read more

Knorr-Bremse Rail Systems UK is proud to present the remarkable achievement of installing the largest curved standing solar roof in the UK at our manufacturing site in Melksham. This ambitious project, completed in February 2023 with a capacity of 565 kW, underscores our unwavering commitment to sustainability and innovation in the rail systems industry.

Read more

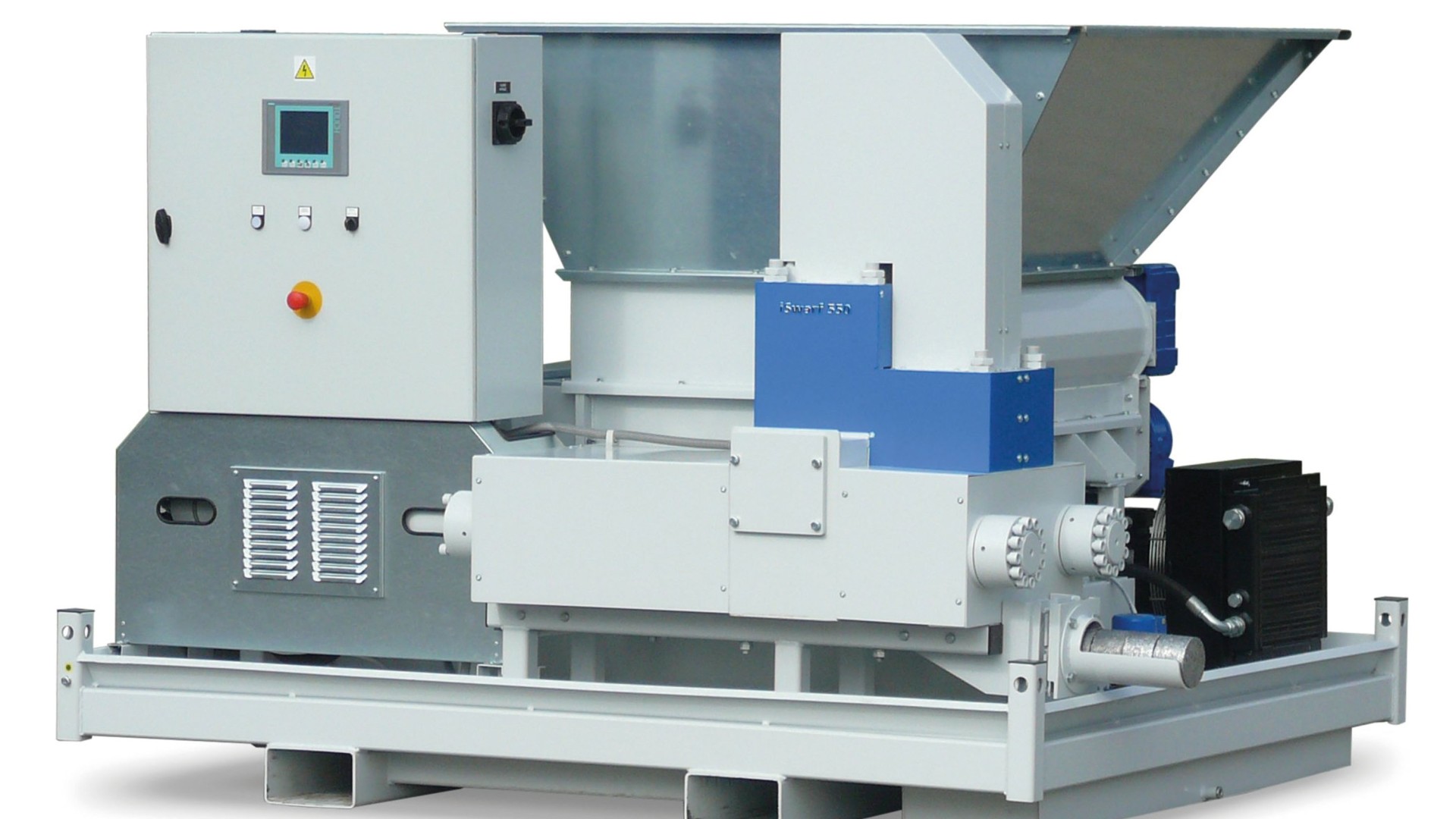

Waste management is a critical component of a circular economy, where valuable raw materials can be reintroduced into the production cycle, minimising environmental burdens. At Knorr-Bremse Rail Systems UK, there is a strong emphasis on waste prevention and recycling. By integrating a metal briquetting machine at their manufacturing site in Corsham, Knorr-Bremse have demonstrated their commitment to sustainability and resource efficiency.

Read more