Compressed air is used to press brake shoes against the brake disc and also in pneumatic suspension, sanding and windscreen wiper applications. The air is supplied by a complex system that distributes it intelligently throughout the rail vehicle via an extensive branched pipe network. In the past, compressors were treated as a standalone element of the train topology, responsible for providing a source of pressure. Today, however, their performance is optimized through an integrated systems approach.

Contacts

80809 München

Deutschland - Germany

sales.sfs@knorr-bremse.com

The ideal system for every application

The trend towards lighter and more compact vehicles with ever higher safety and performance standards poses a challenge for every manufacturer. It means that innovative concepts are required for supplying compressed air to rail vehicles. As an established systems supplier, Knorr-Bremse can draw on extensive resources when designing its air supply systems. The portfolio encompasses a wide range of compressors of different performance categories and designs that can easily be combined to deliver a variety of functionalities, with the aim of designing the ideal system for the relevant operating conditions.

Alongside other factors, one particular feature is also increasingly key to public acceptance of rail transportation. The ability to vary the compressor speed means that the new air supply systems can operate significantly more quietly in critical locations, for instance when vehicles are parked in standby mode in sensitive residential areas or when a train enters a station. These modern systems also ensure a quieter, more comfortable ride for passengers.

Info

Download Product Brochures

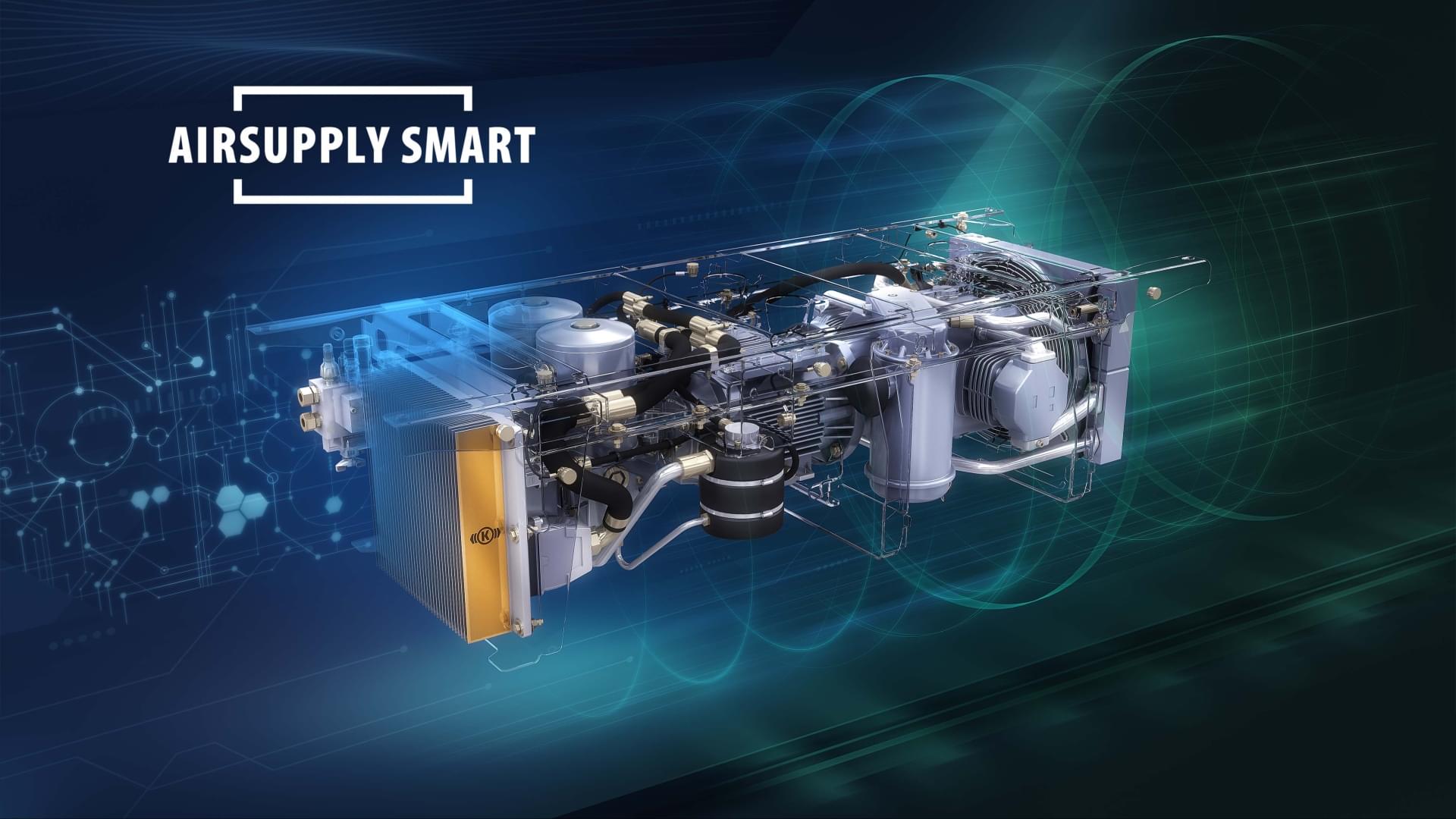

An intelligent air supply unit 'AirSupply Smart' with a groundbreaking new demand and noise management system

The ability to vary compressor speed constitutes a paradigm shift for air supply systems. After decades of only being able to switch the compressor to “on” or “off”, the Intelligent Air Supply Unit 'AirSupply Smart' now provides a smart, multifunctional platform. It is based on a groundbreaking new demand and noise management system that adjusts compressed air delivery to the current operating conditions such as vehicle load, speed, number of braking operations and the topography of the route. This flexibility also allows the compressor to be powered directly by the vehicle battery, removing the need for an auxiliary compressor. The potential for adaptive control coupled with integrated condition monitoring increases vehicle availability while reducing wear and life cycle costs.

The 'AirSupply Smart' offers many customer benefits

- Integrated Pantograph Mode (battery start-up)

- Integrated Boost Mode (for fast fill-up)

- Integrated Silent Mode / Night Mode

- Integrated Full System Condition Monitoring

- Anytime Extendable Functions

- Automatic Mode - to adjust the volume flow to the real demand

- Improved energy efficiency

- Easy system integration

- Reduced LCC

- Reduced weight

- Downsizing potential