80809 München

Deutschland - Germany

sales.sfs@knorr-bremse.com

Train brake discs with optimized friction technologies

The friction pairings perform the physical work of the braking system. Powerful forces transform kinetic energy into heat, causing the train to brake. Optimal friction technologies require a perfectly balanced “pairing”. Knorr-Bremse can supply custom, application-specific friction material pairings for virtually any type of train, meeting almost every rail industry standard around the world. The company’s in-depth understanding of what constitutes the right friction pairing ensures optimized life cycle costs, generating added value for the customer.

All friction pairings are grouped under the heading of Friction Technologies. Knorr-Bremse’s individual product technologies for friction material – sintered and organic pads and blocks – are bundled under its three Friction product ranges: ProPad, ProBlock and UltraPad. The brake discs are marketed under the names UltraDisc, ProDisc and LightDisc.

Contact

Pads

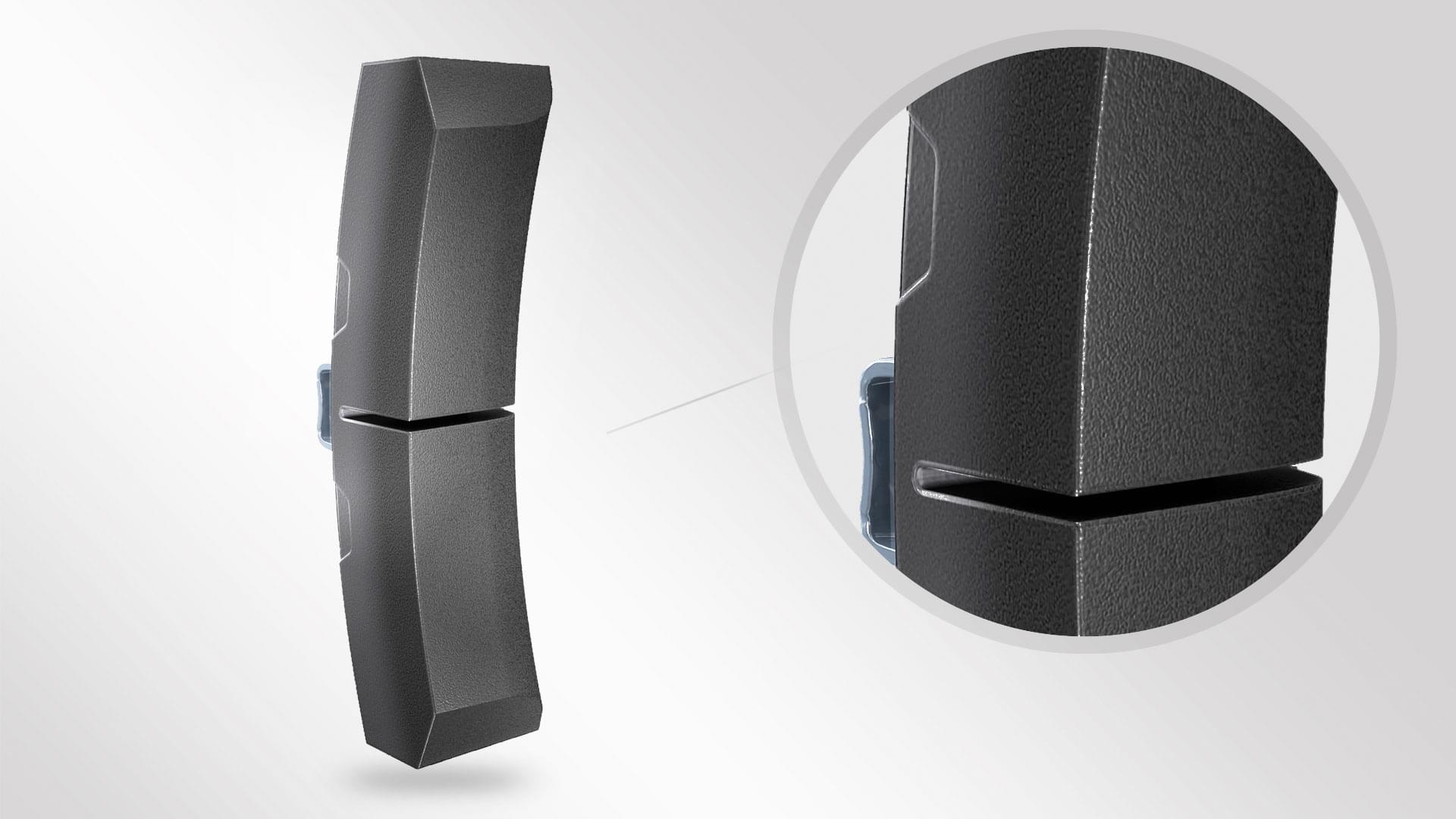

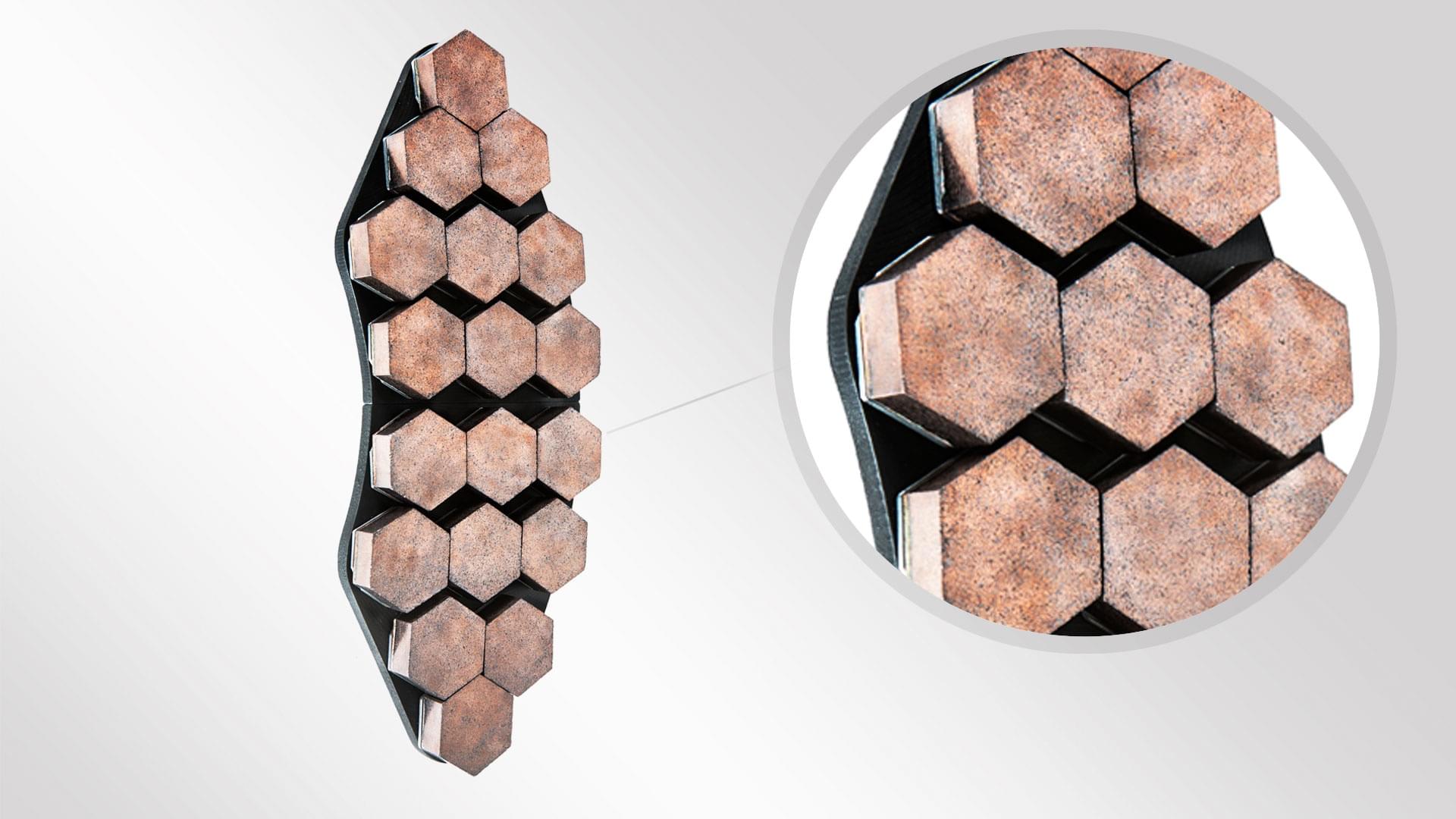

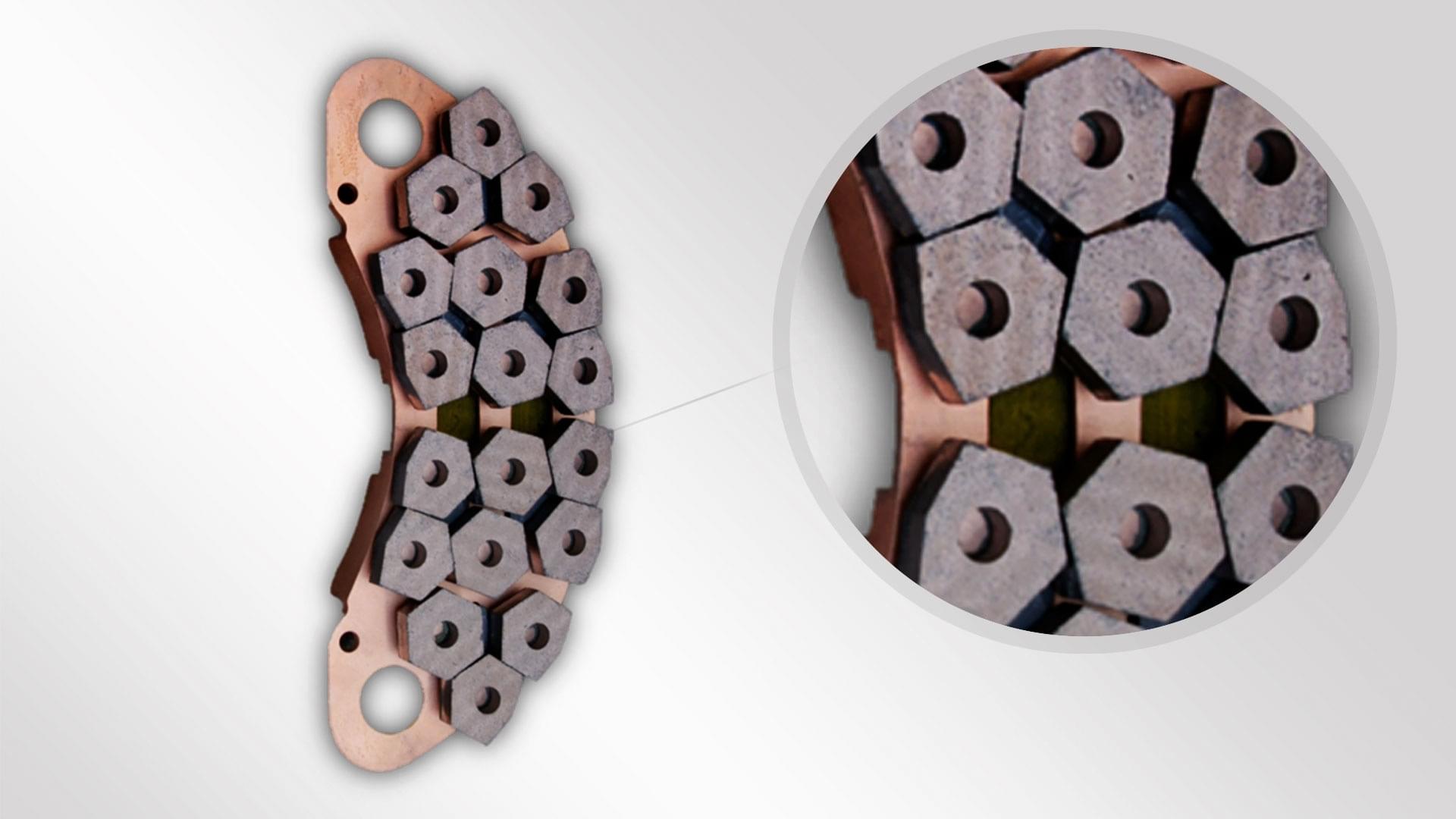

In our brake pad and block ranges, the prefix “Ultra-” denotes sintered products, while “Pro-” denotes organic products. Knorr-Bremse’s ProPad organic brake pads are available as standard brake pads and for hydraulic braking system applications. The 'UltraPad family' of sintered pads includes the high-performance sintered pads 'UltraPad Flex' and 'UltraPad Extreme' (also known as ISOBAR®).

Blocks

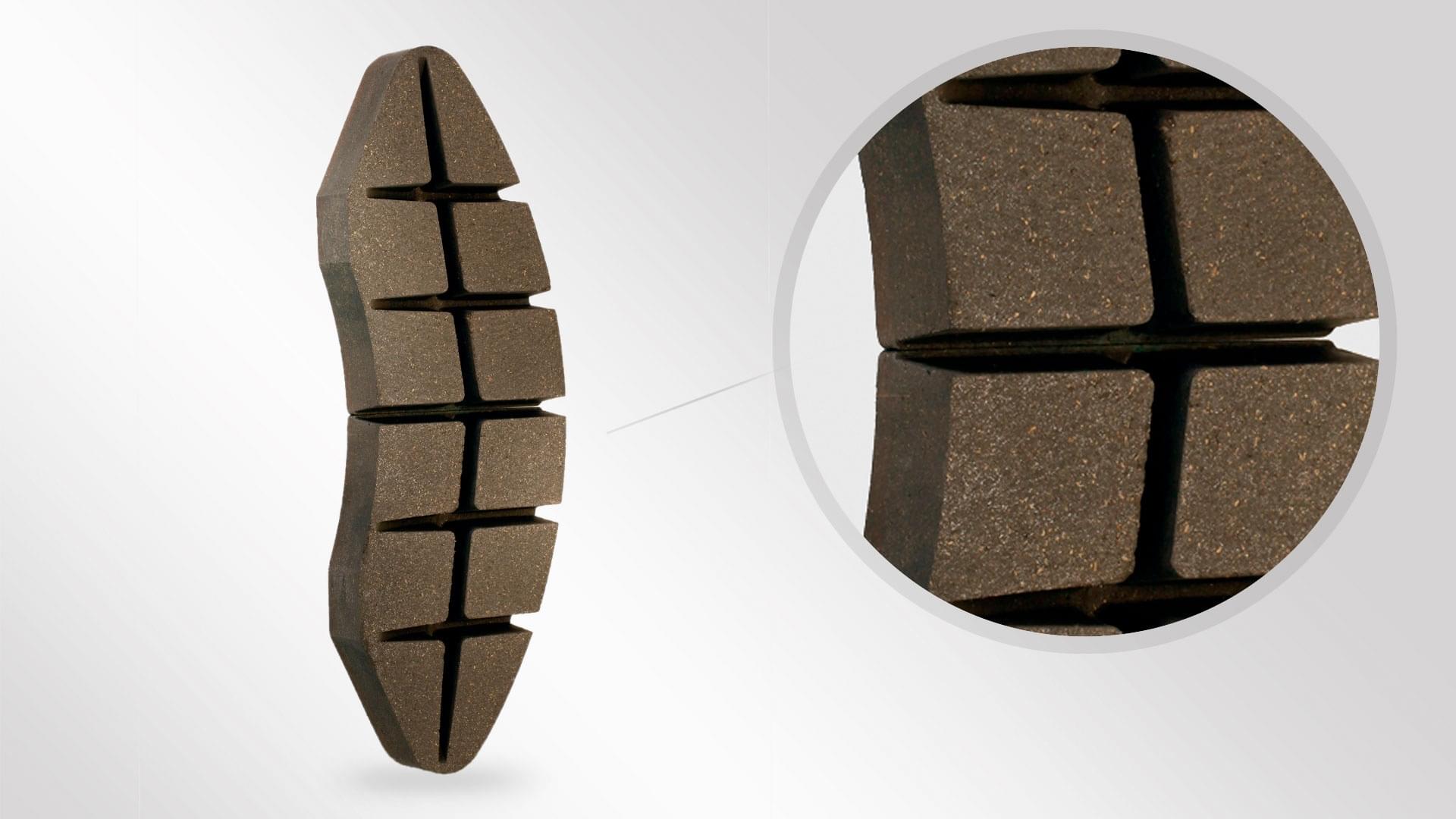

In our brake block range, the 'ProBlock family' features quiet, low-wear organic brake blocks including the “whisper brake” LL blocks and K blocks for freight cars.

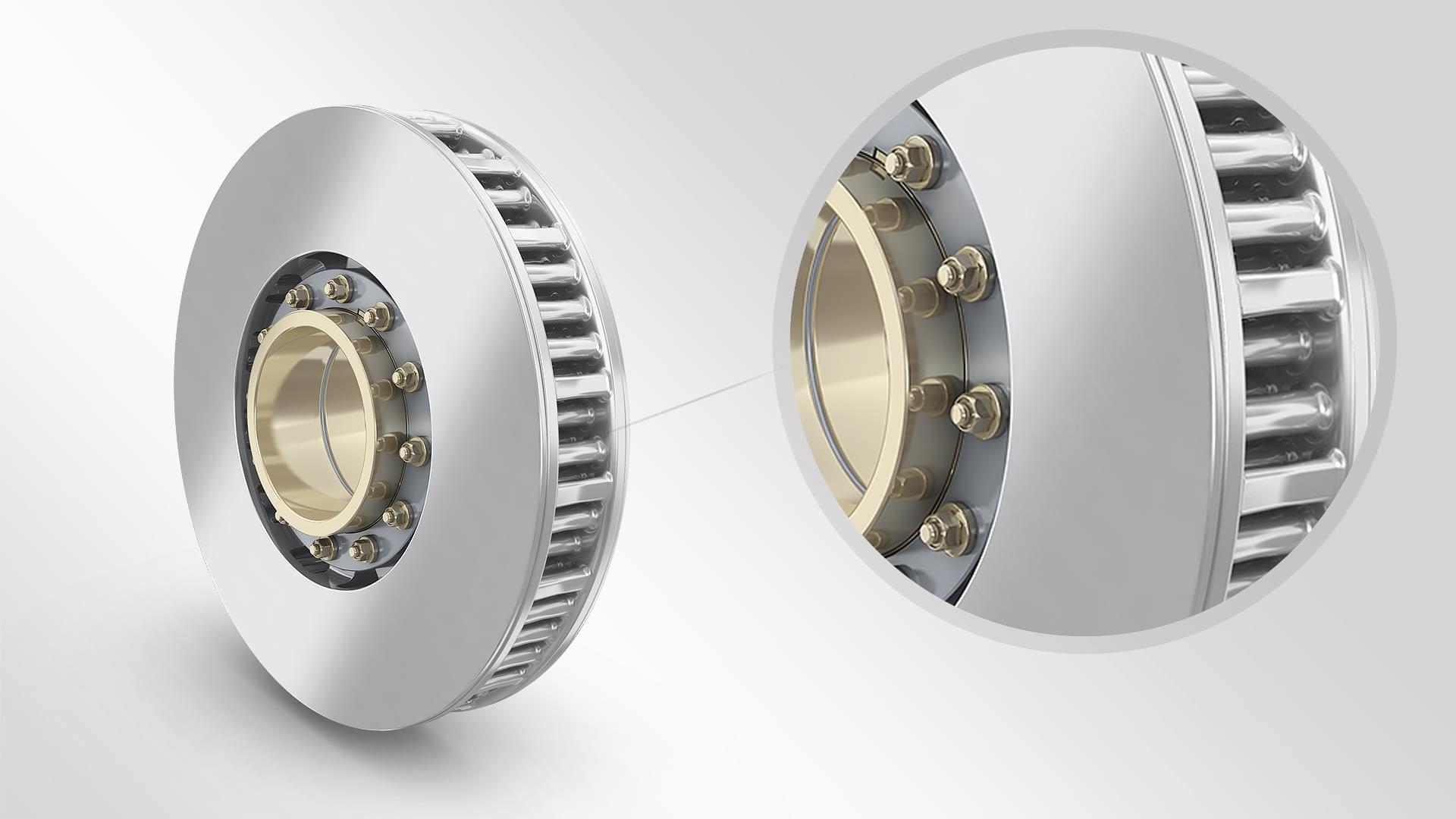

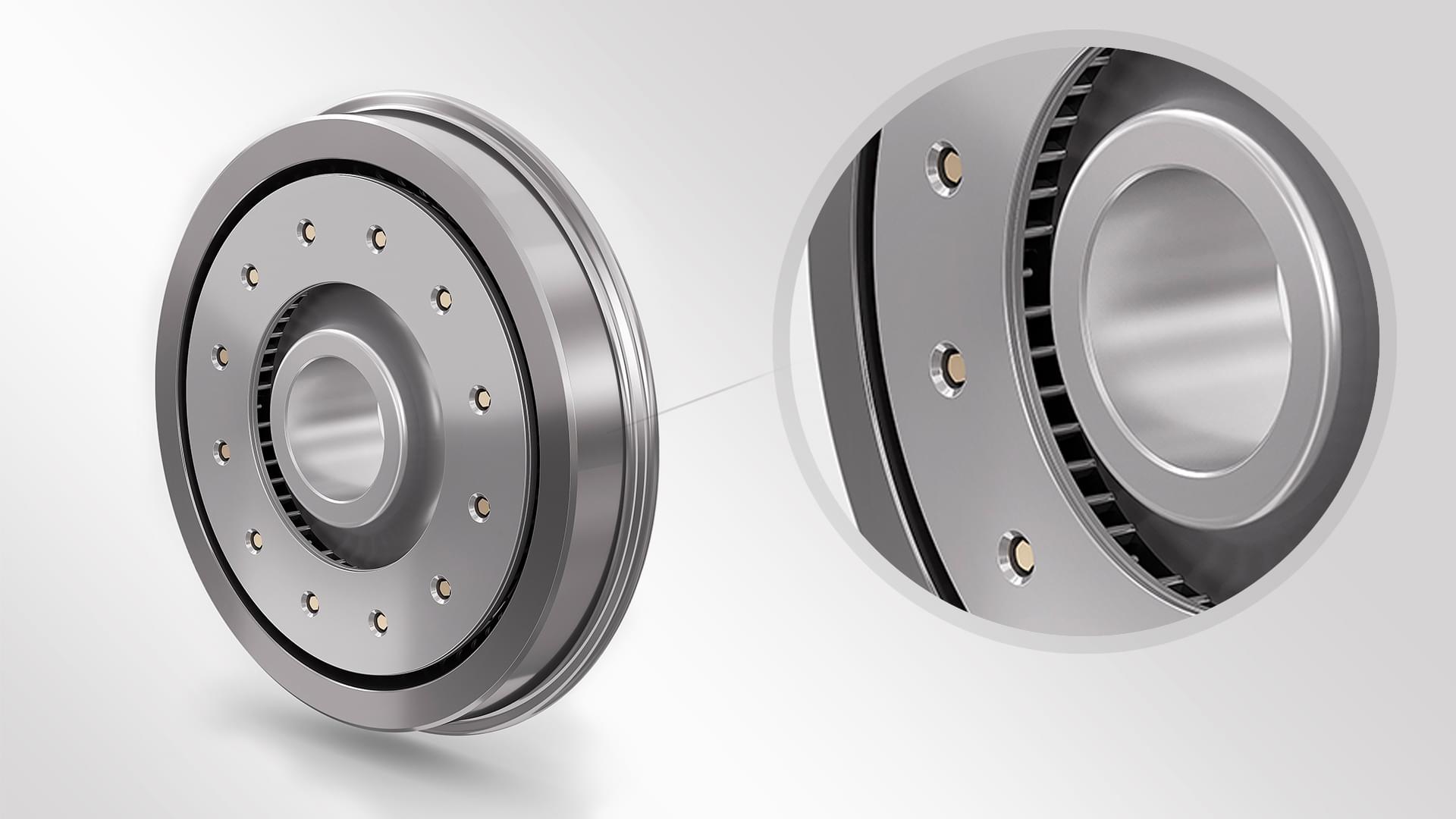

Brake Discs

To achieve the ideal friction pairing, Knorr-Bremse can choose from a modular range of brake discs of many different thicknesses and diameters. The axle- or wheel-mounted discs are available in the widest range of steel, grey cast iron, nodular cast iron and aluminum versions.

Info

Download Product Brochures