Summer is the best time for holidays. And vacation in most cases also means to travel. This summer, our mascot Knorr-Berta travelled across Europe to learn more about Knorr-Bremse, its locations and Group brands as well as the portfolio. Join Knorr-Berta on her exciting journey through Europe.

Greetings to all the lovely readers out there! If we haven't met before, allow me to introduce myself – I'm Knorr-Berta, your Knorr-Bremse teddy bear. Having reached that age where I'm wise and experienced, I'm currently proud to be part of the team at Knorr-Bremse in Munich. And guess what? This year, I've decided to embark on an exciting europetour, and guess who gets to come along? That's right, all of you! Through the power of virtual travel, I'm here to take you on a thrilling journey across Europe.

Here we go!

It all began on a sunny Sunday morning – the day I was all set to explore new horizons. Armed with my trusty backpack and after ensuring my apartment was cleaned up, I made my way to the heart of Munich – the central station. It was there that I would catch my train and kick-start this incredible adventure. As I sit here on the train, I can't help but feel a surge of excitement. The unknown awaits!

I'm ready to soak in different cultures, connect with colleagues, and of course, dive deep into the world of our products and systems.

Hamburg

A warm “top of the morning” to you from my first destination! I arrived in Hamburg and I’ve already seen a lot of this magical city. After scouting out the city that’s also known in Germany as the “Gateway to the World”, I traveled to Altona train station so I could take a suburban train to Wedel. You may be wondering what this city-loving bear is going to do in a small town like Wedel when she could just chill out in Hamburg?

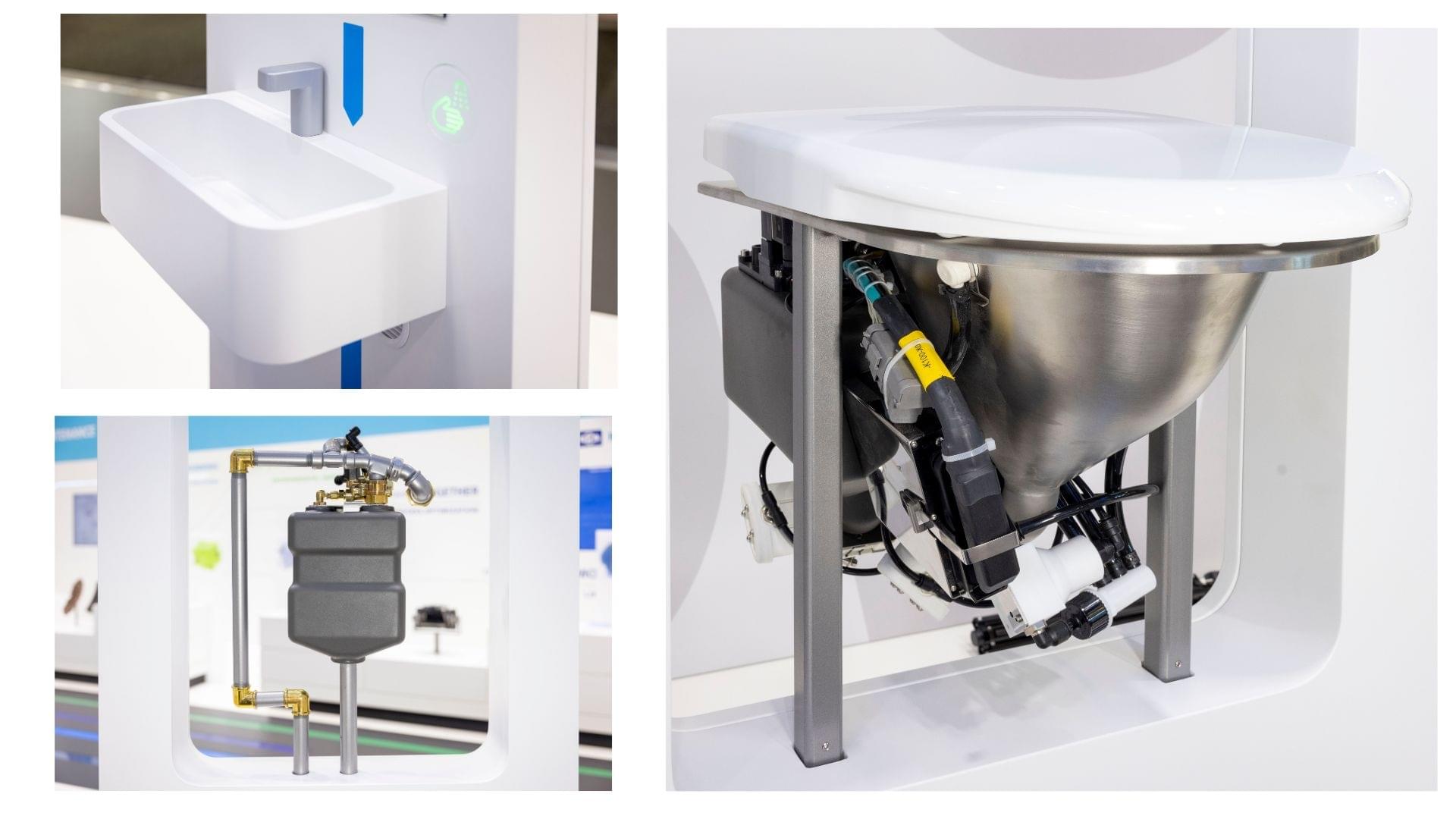

Well, I’ll tell you: My mission was, to visit the headquarters as well as the roughly 200 colleagues of our group brand EVAC! EVAC has been part of the Knorr-Bremse family since 2021 and its product portfolio includes individual sanitary components as well as fully equipped toilet cabins for the original equipment business as well as for various modernization projects.

I must admit that before I visited my colleagues at EVAC, all I knew about them was that they are leading provider of integrated sanitary systems for passenger trains and that they have over 40 years of experience in this field. I can just say: You live and learn! And here are just some of the interesting facts I learned during my visit:

- EVAC introduced the first vacuum toilet to the market back in 1975!

- EVAC systems operate between -40 to +70 degrees Celsius.

- Their installed base is more than 120,000 systems.

- The business unit sanitary has sites in Wedel, Florence (Italy), Palwal (India), and the Watertown (USA).

Did you know that with Knorr-Bremses` worldwide service and spare parts network behind them, EVAC is truly close to their customer wherever rail has been laid in the world? Neither did I, but I was amazed by their range! If you want to learn even more about EVAC just have a look in our Newsforum !

EVAC at InnoTrans 2022 in Berlin

Since 2021 is EVAC part of the Knorr-Bremse Family. Their exhibits were although represented at InnoTrans 2022 in Berlin.

Brussels

Having just spent the last hours in a high-speed train battling boredom by planning my itinerary and enjoying the scenery, I’ve finally arrived at my long-awaited stopover – beautiful Brussels! Sadly, I was only able to spend a very short time there because my next train was already waiting at the next platform. I still managed to grab a “pistolet” roll – a typical Brussels pastry – for a travel snack. So I sat down in my window seat and waited for the train to move out of the station. While I was waiting, I noticed something pretty cool which – of course – I’d like to share with you:

As I was looking out the window, I saw two coupled Belgian multiple units passing by. Well, of course I already know plenty about railway couplers because of my work. In my first few weeks at Knorr-Bremse, I learned how we manufacture coupling systems for passenger trains as well as freight cars.

The big new thing for rail freight is our Digital Automatic Coupler, or “DAC” for short. Our FreightLink DAC is a big step on the way to upgrading rail freight for the digital age! Not only will it automate the coupling process, which is – get this! – still manual; its innovative electrical interface will also make it possible to digitize and automate rail freight transportation.

On the passenger side, meanwhile, you’ve probably heard about the AutoLink center buffer coupler used to connect passenger trains with oneanother. As well as smoothing the coupling process, it also makes train journeys more comfortable and provides maximum safety in critical situations.

Whoops! I’ve just noticed how my brief observation has turned into a great big long explanation. I could talk about this stuff forever… But I won’t. Instead, why not check out our coupling systems website, where you’ll get an even more detailed look into our entire coupler portfolio. Oh, we are moving… I’m really looking forward to my next stop!

Bristol

A great big “hi there” from Bristol, too! After I left Brussels, I traveled right across the UK and finally ended up here in Bristol. On the way, I saw some truly gorgeous scenery – it was like something out of a picture book. Endless green meadows beneath a cloudless, turquoise-blue sky… what more could a wandering teddy bear ask for?

Bristol’s a beautiful city, and I was able to check off (here in the UK, they say “tick off”!) the first item on my bucket list straight away: I spent the morning in a pretty little tearoom, so I started the day in a very relaxed mood.

But let’s get on to the really good stuff: the Knorr-Bremse site in Melksham. Using Bristol’s local public transit system, the trip took me about 40 minutes. After I arrived, I was given a guided tour by several super-lovely colleagues. And during my tour, I found out a few interesting things. So of course I’m going to share them with you:

- This site has the largest curved solar roof in the UK (565 kW), consisting of 1,414 photovoltaic panels that use sunlight to generate clean, renewable energy for powering vital systems such as heating, lighting and air conditioning. The installation is capable of generating 537,488 kWh of electricity per year, avoiding 107,500 kg of carbon emissions. That’s equivalent to planting 13,376 trees – amazing!

- Knorr-Bremse Rail Systems UK manages a total of three sites: Melksham, Corsham in Wiltshire, and Manchester.

- Melksham is where engineering happens and the CubeControl V6 is produced.

- An unused green area at Melksham has been turned into a nature reserve, complete with pond, trees and flowers. Visitors can also find out more about native wildlife.

After my guided tour, I was really impressed by just how multi-talented and enthusiastic my colleagues in Melksham are – actually, that goes for everybody in the UK! If I’ve tickled your curiosity and you’d like to know more about Melksham or the other two UK sites, I suggest you check out their website .

As for me, after spending a couple of great days here, it’s time to say goodbye to Bristol. Okay, I’m a bit sad – but already looking forward to my next destination.

Strasbourg

After spontaneously spending the past 24 hours in Paris (aren’t you just green with envy?), I’m back on a train again and less than an hour away from my next destination – Strasbourg! Since boarding the train at the Gare d’Austerlitz, I’ve spent my time guzzling macarons and looking out the window at the gorgeous French countryside. It’s been a (very) hot day, so I’ve been enjoying the train’s A/C system. And because work isn’t something you can just leave behind you, I found myself thinking about our company brand Merak…

Merak was founded back in 1963, and with around 1600 highly qualified employees and 50 years of expertise, has been an integral part of the Knorr-Bremse family since 2005. As well as a head office in Getafe (ES), it has homes in various other countries around the world.

And guess what? Merak supplies air-conditioning (well, more accurately, HVAC) systems that are both climate-friendly and energy-efficient. These include innovative, efficient technologies that maximize air quality and optimize energy savings by automatically and continuously adjusting the system’s airflow to match the train’s current heating or cooling needs. Merak also uses refrigerants with low global-warming potential, as well as filters that last four times longer than the standard alternatives. Isn’t it a great feeling to know that these things are helping us contribute to a more efficient, eco-friendly mode of transportation?

Whoops, there I go again! I’m getting all excited about air conditioning, and the conductor’s just announced that we’re about to arrive at Strasbourg’s (seriously cool – check it out) central station. But if you’re still curious and want to know more about what Merak does, where it’s located and what projects it’s managing, why not visit their website !

So my agenda for the next couple of days involves taking a good look at Strasbourg and its many charming nooks and crannies before I head off to my next destination.

After enjoying a couple of great days in Strasbourg, I’ve just arrived in Switzerland – more specifically, in Lyss, a large village in the canton of Bern (a “canton” is something like a federal state). Lyss is an old village with lots of history, but over the last 150 years, it’s turned into one of the region’s major industrial centers. Even so, it’s still feels like a village, with cheesemakers, bakers (such as Kambly and his famous “butterfly” cookies) and weekly markets. So I strolled through the alleyways around the marketplace and bought a few souvenirs – cheese, chocolates, some of those “butterfly” cookies – for friends and family, plus of course my colleagues!

Any idea what else is special about Lyss? That’s right – this is where our corporate brand Selectron has its head office, so of course I had to pay them a visit! Selectron was founded in Lyss back in 1956 and joined the Knorr-Bremse Group in 2015. Selectron employs around 120 people and has more than 60 years of experience of developing electronics. As well as Lyss, the company has a development center in Italy.

Selectron supplies TCMS (Train Control and Management System) solutions used for rail vehicle automation. The company specializes in control, remote I/O, connectivity and communication technologies, and develops solutions that comply with the very latest safety and cybersecurity standards. TCMS modules are programmed using highly efficient software tools that allow customers to respond to the latest digital connectivity trends.

And now I really must get going again, because my next stop is already waiting for me! But if you’re as interested in Selectron and its various activities as I am, just take a closer look at the company’s website .

Mödling

Wow! You can’t imagine what a fantastic view I’m enjoying right now! I was allowed into the driver’s cab a little earlier so I could take a look around. And one thing got me totally hooked – the crystal-clear windshield, giving me a breathtaking view of Austria’s spectacular natural landscapes. Those lakes, those mountains in the background – they’re awesome! As you can see from the pictures – it’s like there isn’t any glass in the way! Apparently, it’s all down to the great work of the windshield wiper- and wash systems .

Knorr-Bremse also produces these systems. They’re developed specifically for each project, based on a custom “3D wipe-area and installation analysis” of the vehicle in question. Depending on which system the customer selects, the drive units need no maintenance for up to ten years, even at 300,000 operation cycles per year. And as it happens, these systems are produced in Austria, where I am now! More precisely, they’re manufactured in Mödling, some 7 kilometers (around 4 miles) south of Vienna.

At the Mödling site, Knorr-Bremse Austria has built up years of expertise in windshield wiper and wash systems. The result? Thousands of successful installations, ranging from super-complex, pneumatically driven wiper systems for high-speed trains to electrically driven wiper systems for LRVs – with or without control systems and/or rain sensors. These systems ensure drivers enjoy good visibility in all conditions, anywhere in the world. Safer, anybody? The development of these systems highlights Knorr-Bremse’s unique capabilities, from defining a brand-new system layout right through to modernizing an existing system.

Sadly, on this year’s tour, I won’t be able to visit Mödling or share my impressions of the site with you The good news? I’ve found the LinkedIn channel for Knorr-Bremse Mödling, where you can check out the daily lives of our Austrian colleagues several times a week!

But there’s a bit of bad news too. I’m afraid this is the last diary entry for my grand tour of Europe, because after my two-day stay in Innsbruck, I’m heading home to Munich. But I’m so grateful for the past few weeks – I’ve explored Knorr-Bremse sites, got to know loads of lovely colleagues, and really expanded my knowledge of our product portfolio.

So I’ll just say this one more time: Stay tuned, stay curious, because as well as my travel diary, you’ll find lots of other great Knorr-Bremse stories in our Newsforum. Enjoy!

P.S. Look forward to seeing you again at InnoTrans at the latest!