The rail vehicle industry is seeing the emergence of an equivalent to the Internet of Things – the “Internet of Trains”. And increasingly, this new IoT is determining how IoT-related interactions between the many players in the industry will work in the future. But it will only succeed once a standardized data sharing structure is in place.

To start with, the “Internet of Things” (IoT) was more of a playground for hardcore IT experts: They enabled machines to communicate with each other by fitting them with sensors and networking functions and giving them access to the cloud. Since then, the networking of physical objects has also gained traction in the rail industry – for providing real-time information on train connections, for example, or estimating probable delays for passengers’ convenience. Other applications include predictive maintenance for minimizing downtime, the streamlining of train operations for rail network operators, or the analysis of track conditions and signaling system status for infrastructure owners. All these IoT activities depend on a crucial common element: connectivity between subsystems, vehicles and infrastructure – as well as the ability to scale specific functions across the industry as a whole.

80809 München

Deutschland - Germany

carina.smid@knorr-bremse.com

Joint venture for monitoring the condition of HVAC systems

In 2022, Siemens Mobility and Knorr-Bremse implemented precisely such a scalable solution for the large-scale digital monitoring of HVAC system status in real time. The venture covers 172 regional trains operated by South Western Railway in the UK; the trains’ 733 HVAC systems have been retrofitted with Knorr-Bremse’s condition monitoring solution, in the form of a digital upgrade kit.

The big data collected while the rail vehicles are running is transferred to the joint platform used by both strategic partners, and the resulting insights are processed with the assistance of AI to create a comprehensive HVAC system monitoring function. Data on temperatures, for example, is used to measure the performance of the air-conditioning systems in operation. Clear, user-friendly graphics displayed on a “data dashboard” enable the service teams in Siemens Mobility workshops to identify potentially necessary repairs at an early stage and tackle them proactively, long before unplanned repairs impact vehicle operations.

CO2 sensor systems have also been installed, providing further big data insights with similar “IoT” functionality. If the air quality falls below a (preset) threshold, the control system increases the supply of fresh air. Because fresh air often needs to be cooled or heated, this demand-based air supply reduces energy consumption and improves the train’s eco-footprint. During the Covid-19 pandemic, it was easy to reverse the underlying logic and deliberately increase the inflow of fresh air to improve the air quality in carriages and passenger compartments.

There are already comparatively straightforward ways for individual vehicle manufacturers to share operating data with individual subsystems suppliers via a project-specific interface. But for the rail industry as a whole to take full advantage of the value added by digitalization, data from a large number of industry players is required. In the best-case scenario, such data would depict the entire value chain.

To interact via IoT, the rail industry must be willing to change

The downside: As the number of players grows, so too does the complexity of the collaboration between them. The following example puts this in context: A sensor system monitoring an axle bearing reports abnormal vibration values, indicating that the bearing will soon fail. With the help of predictive maintenance – of which this is a classic example – it should be easy to replace the defective axle bearing and quite probably avoid unscheduled vehicle downtime. But the next level of value added can only be achieved by adding further information into the mix – so in our example: Were other axle bearings affected in the same way after traveling over the same route? Then perhaps the cause is lurking in a particular section of track. Information like this would make it possible to rapidly identify and repair damaged or defective rails, thereby ensuring that they do not cause similar damage to other axle bearings, vehicle components or vehicles. And vice versa: Such intelligence could also help to avoid unnecessary damage to rail infrastructure as a result of delayed vehicle repairs. Once again, this shows that while data from individual (sub)systems provides valuable information in isolation, the information becomes even more valuable when data from multiple (sub)systems is aggregated.

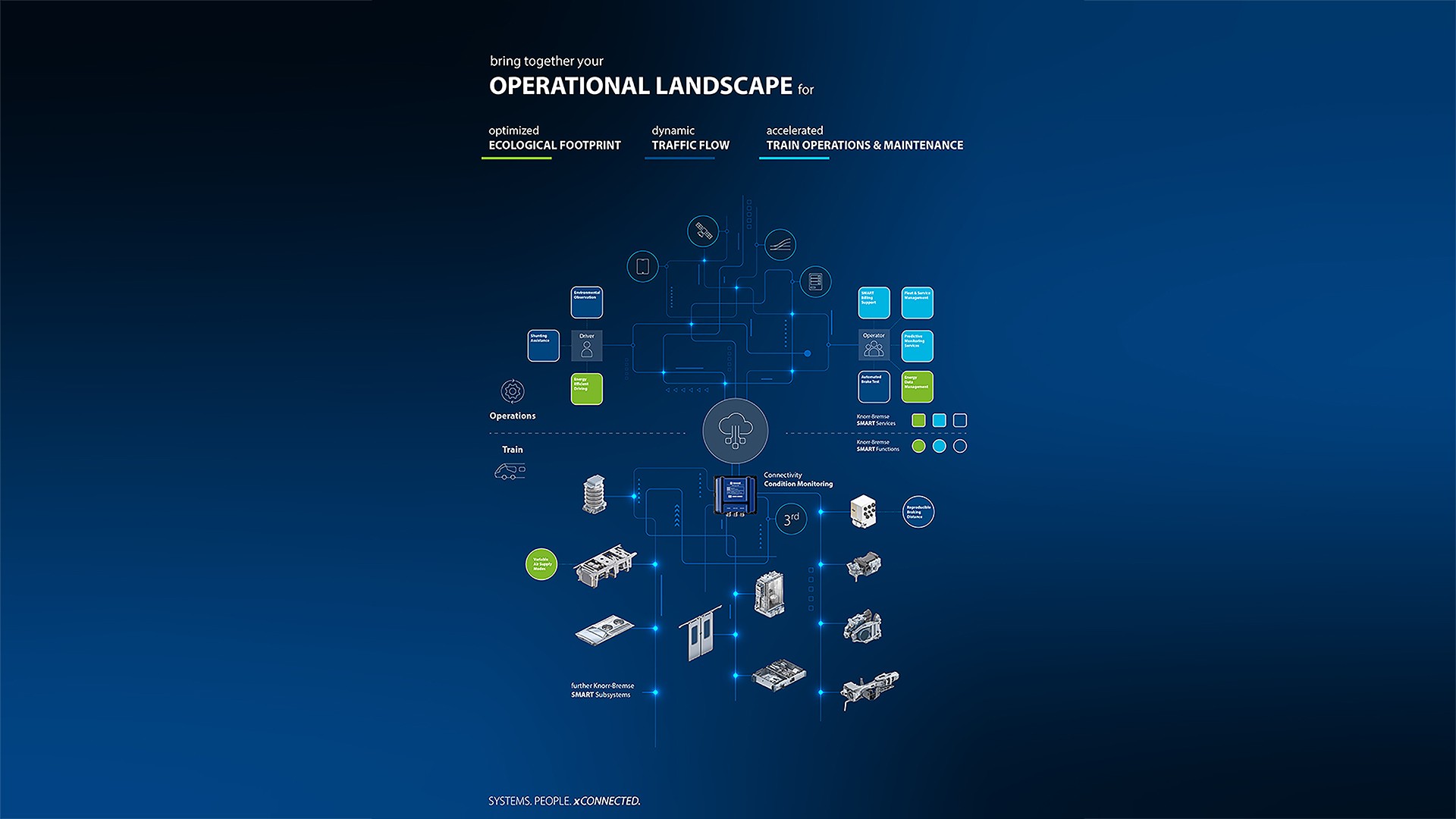

As a rule, fleet operators – and even vehicle manufacturers – only have limited options for identifying broader issues based on the data supplied by subsystems or components. System manufacturers, on the other hand, are in an excellent position to do so. To add new value to all aspects of rail operations, from planning to management, diagnostics to maintenance, asset management to customer services, as much data as possible should be provided by an ever larger number of industry players – in real time. Ideally, the entire value chain should be involved, with all players able to read and analyze the data and integrate it into their services.

The next step, then, is to acknowledge that any comprehensive sharing of data involves a constant give and take. It is now generally agreed that the actual data always belongs to the owner of the asset concerned – meaning, as a rule, the vehicle operator. If the latter wants to leverage their asset and take full advantage of the opportunities offered by the IoT, they must also be willing to share the asset’s data. But asset owners will only be willing to share data if the relevant IoT applications and the value they add are clearly and transparently explained. This in turn means that all those involved must think in terms of opportunities, rather than allowing themselves to be deterred by risks.

To establish and scale the standards and formats required to share data, close collaboration between competitors – in the sense of “coopetition” – is absolutely vital. But the success of this coopetition will stand or fall with the creation of a standardized data space dedicated to the world of rail vehicles.

Trustworthy architecture based on Gaia-X and the EU’s common European data spaces

Such a Rail Data Space forms part of the FA1 “MOTIONAL” work package of the Europe’s Rail Joint Undertaking (ERJU) under the Horizon Europe research program (2021 to 2027) . The aim is to build an open, secure and trustworthy architecture, as proposed by the EU Data Act, that will enable the players involved to effectively share their data for the purpose of networking their business processes.

When seeking appropriate technical solutions, there is no need to reinvent the wheel. There are many positive reasons for basing such a concept on the Gaia-X joint project, the framework within which a sovereign cloud and data infrastructure for Europe is currently being developed. This structure could provide the necessary technical foundation; the next step would be to set up a decentralized Rail Data Space as an active platform for the rail industry as a whole.

It goes without saying that the development of such a data space would need to take account of a wide range of issues, including data protection, data security and intellectual property, as well as ways to enable data owners to control their own data, and the use of state-of-the-art, AI-assisted processing solutions to analyze and predict data. Again, another look at EU-level projects suggests a possible solution: The common European data spaces developed as part of the EU Data Strategy provide a standardized, interoperable framework for sharing data within the EU.

Ultimately, this concept could bring about the emergence of an “Internet of Trains” or even an “Internet of Mobility” (IoM), by networking together vehicles – including their subsystems and components – with fleet operators and depots, infrastructure owners, stations and stops, control centers, IT service providers and eventually also (multimodal) information portals and individual travelers’ smartphones.

Such a holistic focus on the rail sector, let alone the mobility sector as a whole, undoubtedly represents a huge challenge. But the value added for the urbanized world would be enormous: The industry would reach a key milestone in the creation of an intelligent, end-to-end transportation system capable of carrying people and freight to their destinations faster, more efficiently and more affordably by responding more precisely to individual needs.