Sanding systems 'SandGrip', wheel slide protection 'WheelGrip' and cleaning blocks 'TreadGrip' all make a valuable contribution to improving adhesion when it is impaired by factors such as leaves or aerosol deposits on the line, or mist and drizzle. Sanding systems in particular play a critical role, primarily when the vehicle is setting off, accelerating or braking. Over the years, sanding systems have evolved from simple devices into genuinely high-tech systems that are indispensable for safe and efficient rail transportation.

Contact

80809 München

Deutschland - Germany

sales.sfs@knorr-bremse.com

Wheel Slide Protection 'WheelGrip' and Cleaning Blocks 'TradGrip' for Optimal Braking Performance

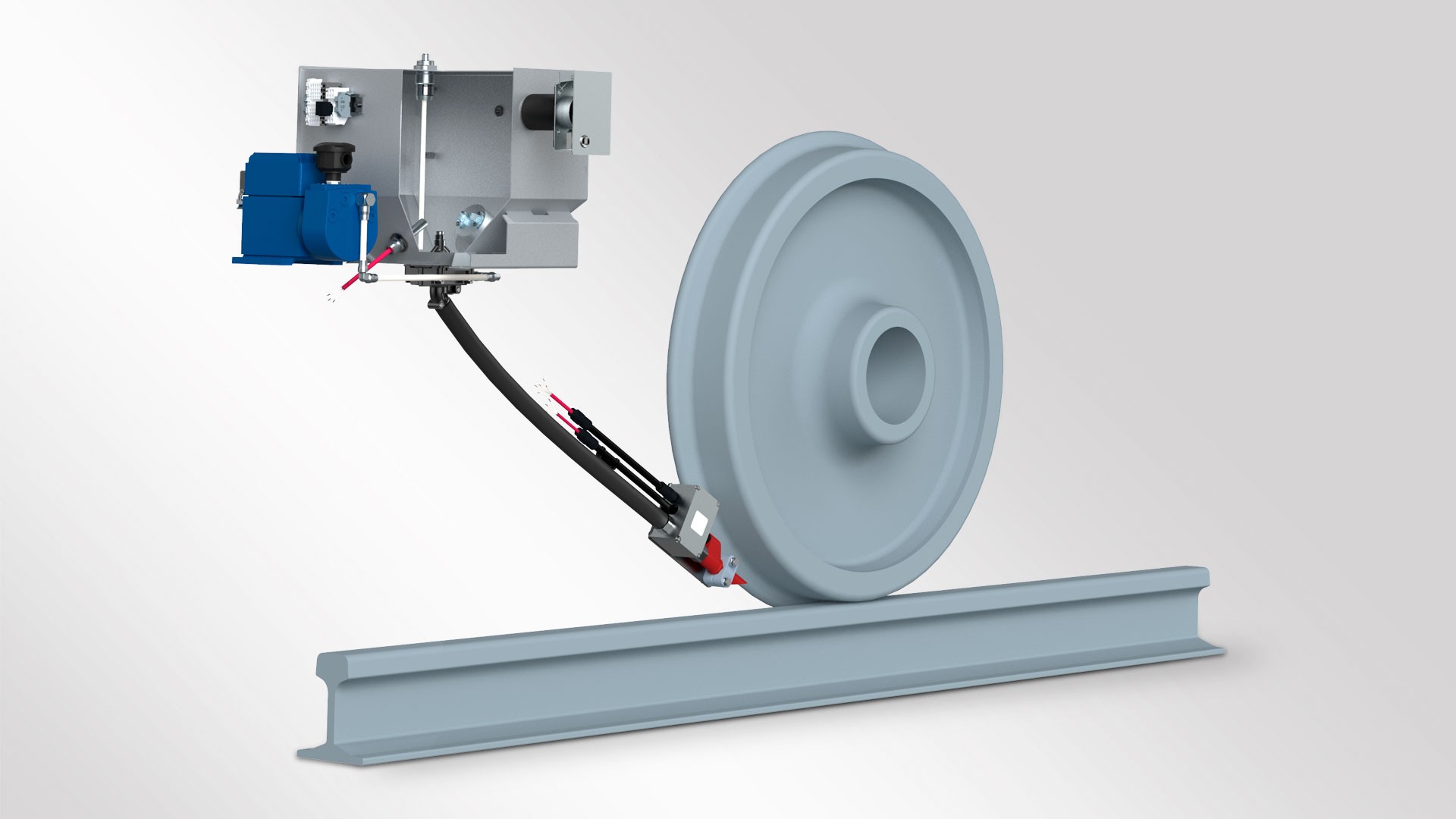

The same is true for the 'WheelGrip family' that is integrated into our Knorr-Bremse’s braking systems in order to maximize wheel-rail adhesion. Knorr-Bremse’s adaptive systems are ideal for low and extremely low adhesion conditions. Cleaning blocks that can be flexibly mounted on the bogie optimize the wheel surface condition.

Adhesion Management with Project-specific Sanding System Designs 'SandGrip'

Sanding systems 'SandGrip' are employed when low wheel-rail adhesion makes it difficult to operate rail vehicles reliably. They improve braking distances in adverse conditions by blowing sand between the wheel and the rail, ensuring that the required adhesion level is reliably achieved. State-of-the-art systems now feature project-specific designs with speed-controlled sand delivery. The quantity of sand delivered in a given operating situation is determined by a sophisticated brake management system.

Info

Download Product Brochures