Train couplers are complex multipurpose systems that take care of the mechanical, pneumatic, electrical and digital connections within and between trainsets. At the same time, they manage huge tensile and compressive forces while compensating for the relative movements of railcars in operation. In short, railway couplers ensure that trains run safely, smoothly, but also economically. And now the digital automatic coupler is about to propel rail freight into the 21st century and help to achieve the climate targets by enabling the Digital Freight Train.

Contact

80809 München

Deutschland - Germany

Since entering the passenger and freight train coupling business in 2019, Knorr-Bremse has also started to cover other safety-related aspects of the holistic system of a train. Knorr-Bremse is now using its longstanding expertise as a market-leading innovator of rail vehicle systems and the tradition in coupler manufacturing. Through its unique service network in more than 40 countries, with countless field service locations around the world, Knorr-Bremse now provides top-quality, on-site customer support for its train couplers as well.

Passenger train couplers were transformed into digital interfaces a long time ago – and now Knorr-Bremse is driving efforts to change Europe’s freight trains in the same way by introducing a digital automatic center buffer coupler. To achieve this, the company has embedded its own Digital Automatic Coupler (DAC) in the end-to-end system that is the Knorr-Bremse Digital Freight Train (DFT).

Coupling portfolio

Download Knorr-Bremse's coupling portfolio

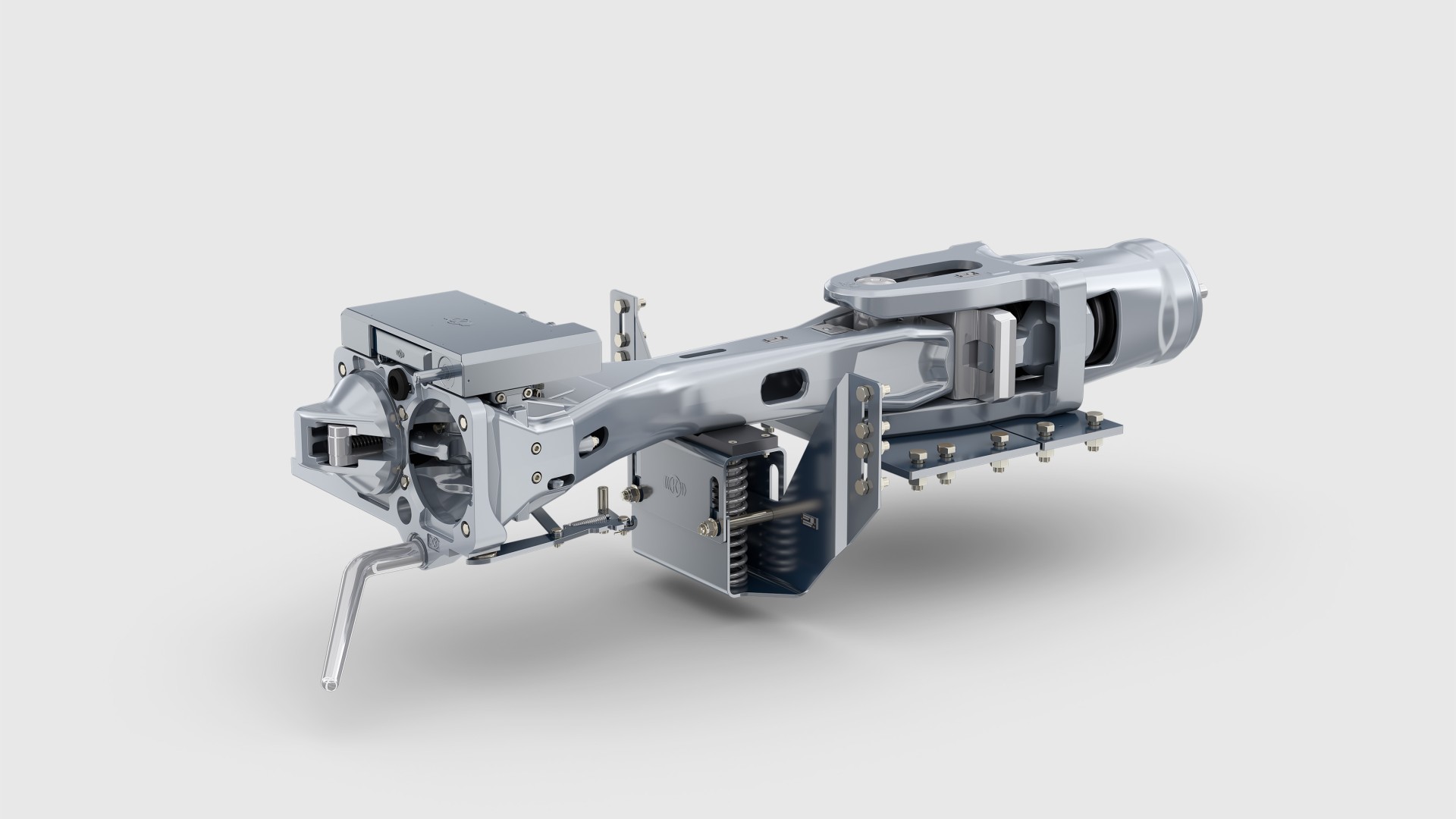

Knorr-Bremse's coupling systems

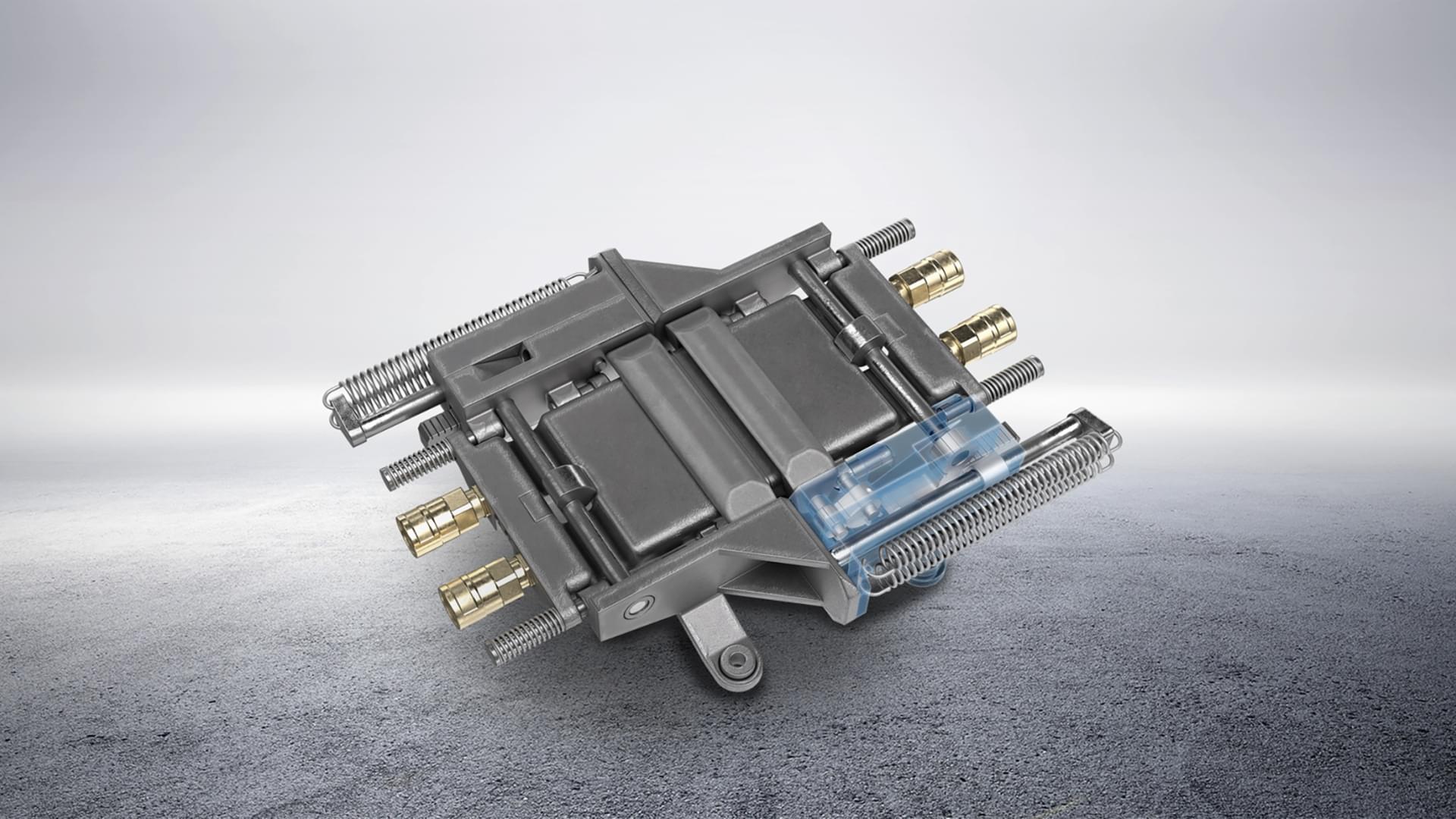

A reliable, safe, long-lasting passenger train coupler significantly enhances the availability of both trains and fleets – and so to a safe, smooth traffic flow for an ever-increasing number of passengers. Train couplers are part of a family of safety-relevant rail vehicle systems, and a key component of the energy absorption system that takes care of passive safety aboard trains.

Find out more about Automatic Coupling Solutions for passenger transport!

To ensure that more freight is transported by rail, the rail freight industry needs to become more efficient and competitive. The Digital Freight Train (DFT), with the Digital Automatic Coupler (DAC) as its core component, is initiating a groundbreaking transformation that will make a key contribution to achieving the European Union’s climate targets.

Find out more about the Digital Automatic Coupler for freight transport!

Coupling systems – tested in Europe, reliable worldwide

For over a century, Knorr-Bremse has been an icon of technical excellence in the rail industry. With more than 120 years of experience in developing innovative rail systems as well as the service skills required to maintain, repair and upgrade them, we combine in-depth expertise with state-of-the-art technology.

Our coupling systems build on this tradition of quality, backed up by cutting-edge test facilities at our in-house test centers. Our Budapest plant plays an especially important role here: This is where we develop our products – and then test and validate them in realistic conditions.

State-of-the-art test facilities in Budapest ensure market-leading safety and reliability

When we develop Knorr-Bremse coupling systems, quality is always our top priority. Regardless of type, all our coupling systems – from automatic front couplers to semi-permanent and adapter couplers right through to our Digital Automatic Coupler for the rail freight market – are directly subjected to the most rigorous testing and validation processes at our cutting-edge test facilities in Budapest. This is how we ensure that every single product meets our customers’ exacting requirements.

Using state-of-the-art test rigs to optimize safety

Our Budapest Test Center boasts some of the world’s most advanced test facilities. They allow us to perform comprehensive static and dynamic tests in realistic conditions:

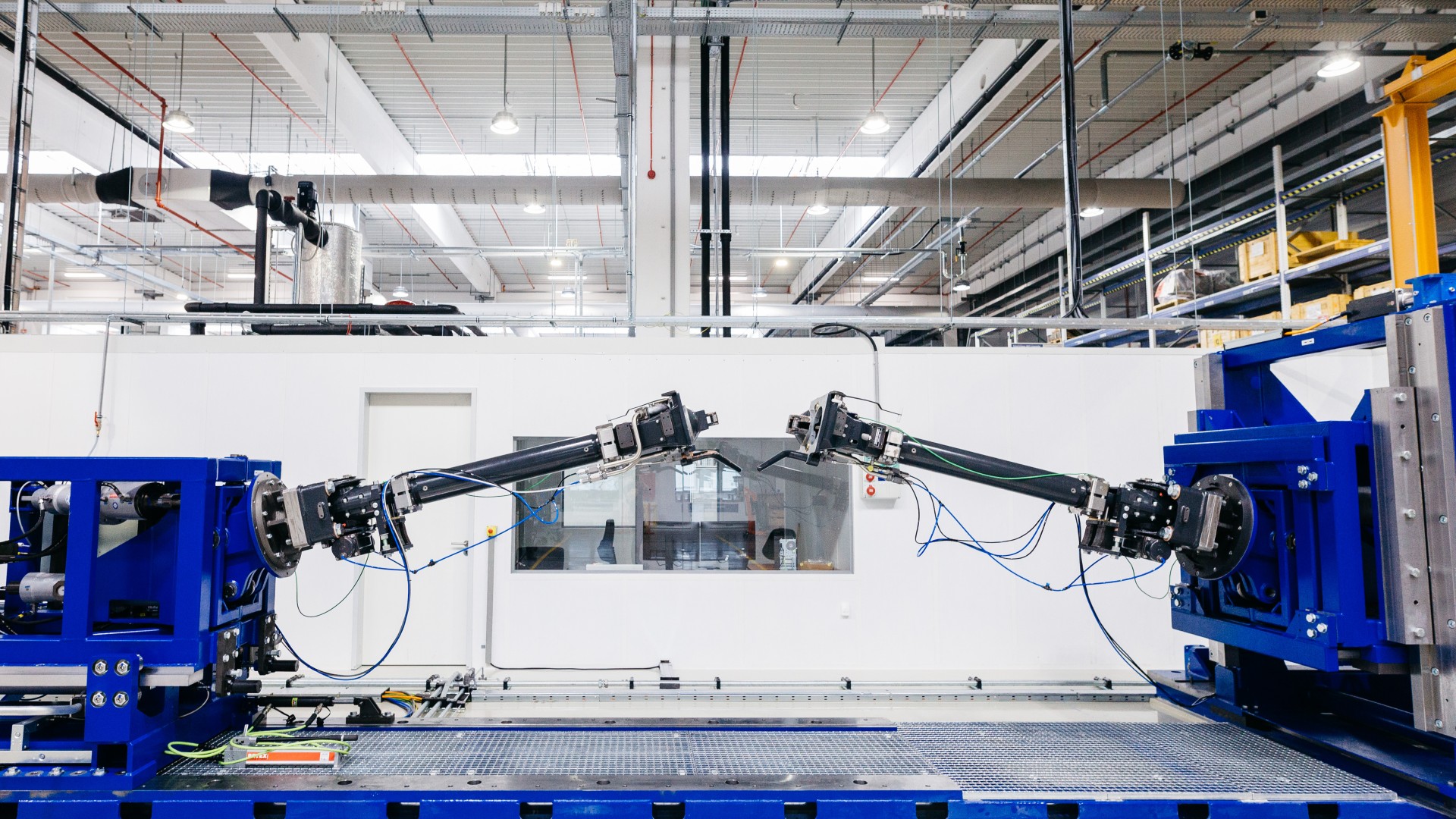

- Functional test benches for simulating any kind of coupling scenario at speeds of up to 5 kph

- Static test benches for precisely simulating mechanical stresses of up to 3,000 kN

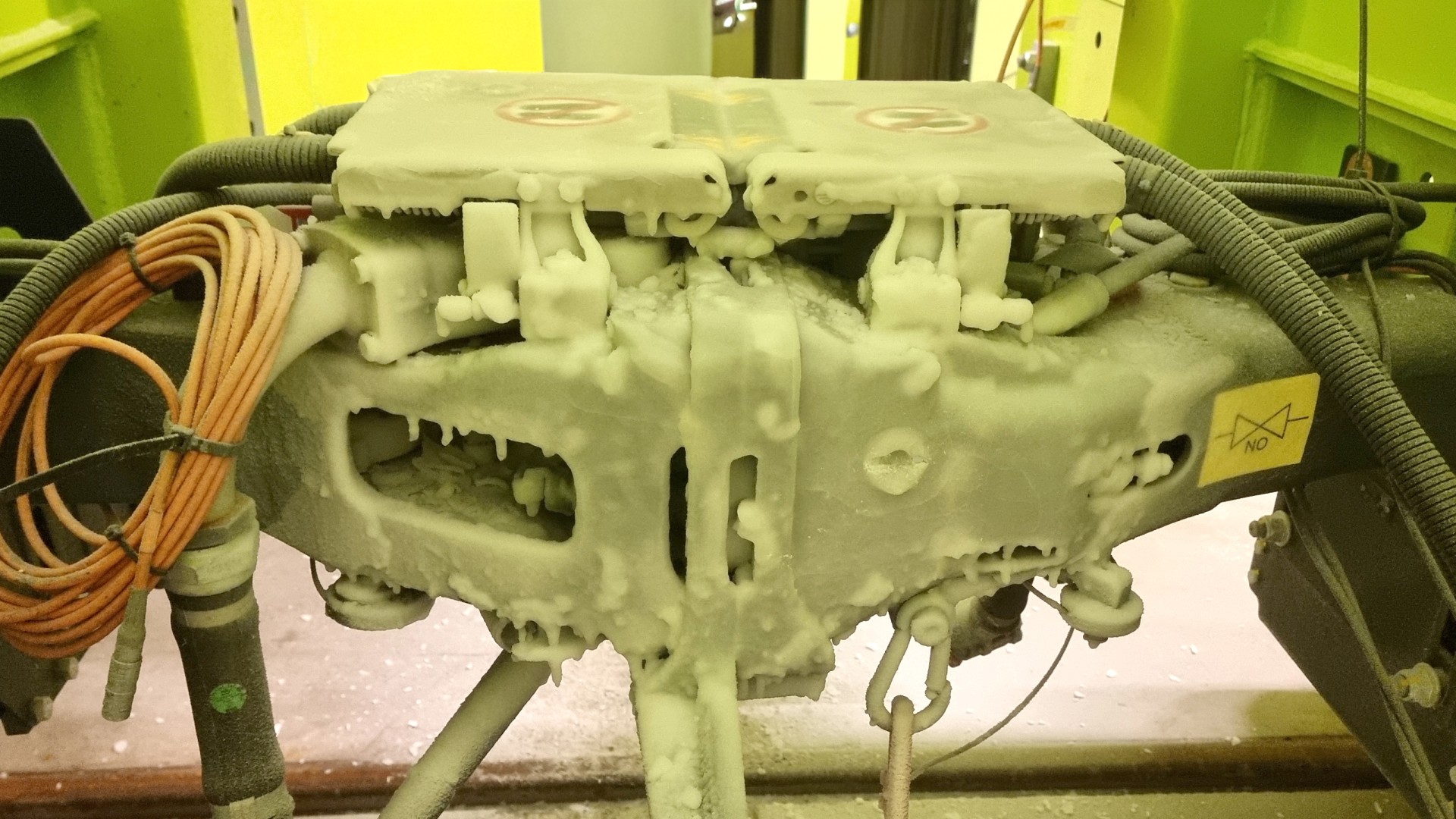

- Climate chambers for validating systems in extreme environmental conditions

- Our high-performance press for designing and validating irreversible energy absorption components

Thanks to this infrastructure, we are able to guarantee the functionality, durability and service life of our couplers long before they are actually used in the field.

Using external tests to further enhance quality

As well as our in-house test facilities in Budapest, we also selectively use external test facilities to ensure that our coupling systems are always totally dependable in an even broader range of conditions. The following are especially important:

- Climate chamber tests of products in the vehicle: Here, we expose our products to extreme temperature and humidity cycles to ensure that they remain fully functional in interaction with the vehicle under all climatic conditions.

- Crash tests: Working together with specialized test centers, we simulate realistic crash scenarios so we can test the structural integrity and safety of our couplers even in the most challenging dynamic scenarios.

By performing these external tests, we ensure that our systems not only comply with European standards but also meet the world’s most exacting safety and quality standards.

In-house expertise with an uncompromising focus on quality

Almost all our modules, including our electric contact coupler, are developed, tested and manufactured in-house by Knorr-Bremse. Our engineering teams have decades of experience in the design, validation and servicing of safety-critical rail components and work closely with our global service network to optimize fleet availability.

Type Test Bench

Functional test bench with six degrees of freedom for simulating any coupling scenario at speeds of up to 5 kph.

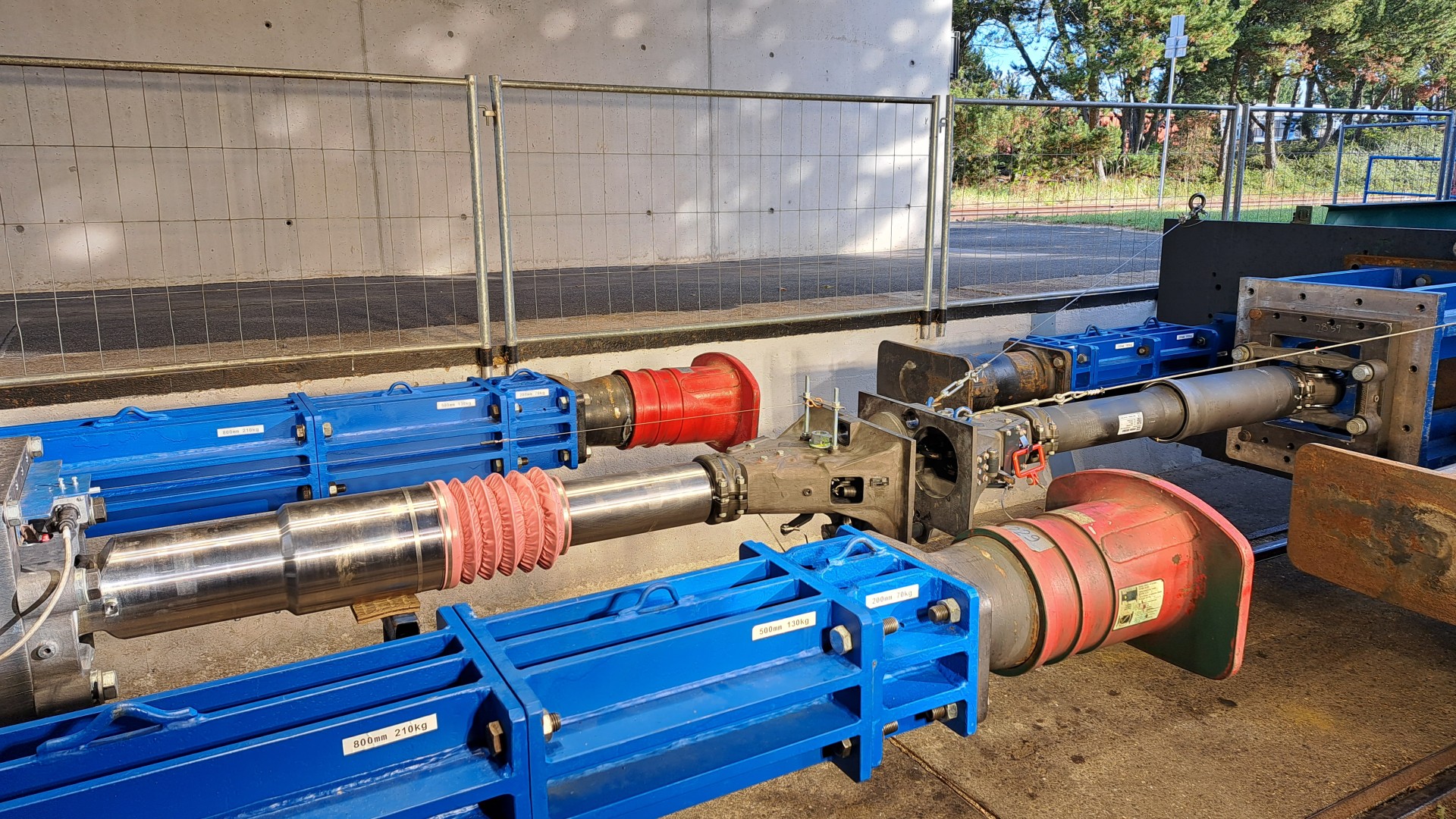

High-performance Press

High-performance press for designing and validating irreversible energy absorption components.

Static Test Bench

Static test bench for stress testing under compressive forces of up to 3,000 kN and tensile forces of up to 2,500 kN.

More interesting topics about coupling systems

Press release “Knorr-Bremse equips metro trains for the Rome metro for Hitachi Rail”

Press release “Munich S-Bahn: Knorr-Bremse equips new trains with couplers”

The Digital Automatic Coupler as an enabler of the Digital Freight Train

Press release "Knorr-Bremse equips passenger trains with coupling systems for the first time"

Press release "Knorr-Bremse tests innovative electric contact coupler"